In the realm of geotechnical engineering, projects often face formidable challenges such as unstable soil conditions, high tensile forces, and the need for rapid installation in cohesive or unconsolidated grounds. SupAnchor, as Asia's leading manufacturer and exporter of self-drilling anchors, addresses these issues with the introduction of the Grade 75 self-drilling hollow anchor. This high-strength variant is designed to meet the escalating demands of modern infrastructure, offering superior load-bearing capacity while maintaining the efficiency of the proven "3-in-1 principle." By integrating drilling, grouting, and reinforcement into a single system, SupAnchor enhances construction speed and safety, reducing risks associated with traditional methods. This innovation is pivotal for projects ranging from deep foundations to tunnel supports, where reliability and performance are paramount.

The Grade 75 self-drilling hollow anchor builds on SupAnchor's extensive product line, leveraging high-strength steel to deliver exceptional mechanical properties. Key features include the 3-in-1 integration, which combines a sacrificial drilling rod, injection tube, and reinforcing bar into a ribbed hollow bar, eliminating the need for separate casing and streamlining on-site operations. This design not only improves efficiency but also ensures robust bonding with grouting materials, thanks to an optimized rib structure that minimizes soil disturbance. The anchor's high tensile and yield strengths make it ideal for heavy-load applications, such as reinforcing deep foundations or stabilizing slopes in geotechnically complex environments. Below is a summary of inferred technical data based on SupAnchor's standardized logic, highlighting parameters that underscore its engineering adaptability and value.

| Parameter | Grade 75 R32 Model | Grade 75 R38 Model |

|---|---|---|

| Outside Diameter (mm) | 32 | 38 |

| Internal Diameter (mm) | 18-20 | 19-21 |

| Cross Sectional Area (mm²) | 400-450 | 600-650 |

| Ultimate Load (kN) | ≥380-420 | ≥550-600 |

| Yield Load (kN) | ≥300-340 | ≥440-480 |

| Weight (kg/m) | 3.2-3.6 | 4.7-5.1 |

| Thread Type | ISO 10208 - R32 | ISO 10208 - R38 |

| Steel Grade | Grade 75 | Grade 75 |

| Elongation (%) | A100mm ≥6 | A100mm ≥6 |

These specifications enable the Grade 75 anchor to tackle engineering challenges by providing higher load thresholds than standard models, ensuring structural integrity under extreme conditions. For instance, in soft soil with high settlement risks, the anchor's high strength resists deformation, while its compatibility with anti-corrosion treatments like hot-dip galvanizing extends its lifespan in damp environments. This makes the self drilling anchor system a versatile solution for diverse geotechnical needs, enhancing safety and reducing project timelines through efficient installation processes.

The Grade 75 self-drilling hollow anchor is tailored for a wide range of demanding applications in geotechnical engineering. Its superior load-bearing capacity makes it suitable for heavy-duty infrastructure projects, such as deep foundation reinforcement for skyscrapers or anchor systems for large-span bridges. In challenging ground conditions, like those encountered in tunnel excavation for highways or railways, this anchor provides reliable support against soil pressure and structural deformation. Additionally, it serves critical roles in permanent support structures, including nuclear power plant auxiliaries or industrial foundations, where long-term reliability is essential. The drill-and-grout bolt functionality allows for quick deployment in cohesive soils, minimizing disruption and maximizing efficiency on site.

These scenarios highlight the anchor's adaptability, making it a cornerstone of modern geotechnical reinforcement systems that prioritize safety and performance.

The introduction of the Grade 75 self-drilling hollow anchor underscores SupAnchor's commitment to innovation and excellence in the global geotechnical sector. As the No. 1 manufacturer and exporter in Asia, SupAnchor leverages extensive R&D and adherence to international standards like ISO 10208 and ISO 1720 to deliver products that meet the highest quality benchmarks. This anchor not only addresses the growing demand for high-strength solutions in infrastructure development but also contributes to geotechnical safety by reducing the risk of failures in critical projects. SupAnchor's collaborative approach with engineers and contractors ensures that their products are tailored to real-world needs, fostering trust and reliability across industries such as tunneling, mining, and civil engineering. By continuously expanding their product portfolio with innovations like the Grade 75 variant, SupAnchor reinforces its position as a leader in the self drilling anchor bolt market, driving progress in sustainable and efficient construction practices worldwide.

SupAnchor's self-drilling anchor system ensures stable foundations in challenging soil conditions, supporting global infrastructure projects with advanced geotechnical solutions.

SupAnchor's SupCT Bolt System offers high ductility and corrosion resistance for tunneling and mining. Features include factory-preassembled components and optimized grouting design, enhancing safety and efficiency.

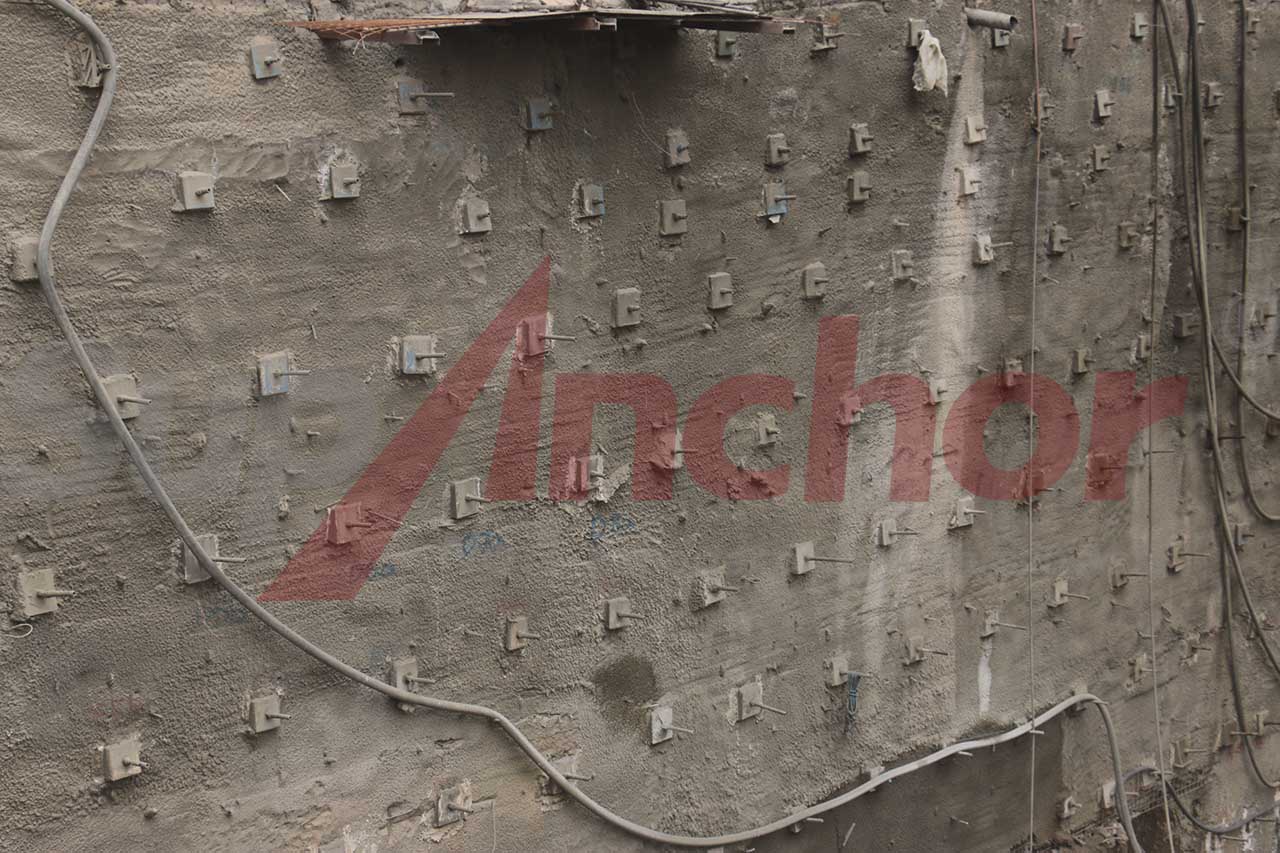

SupAnchor's self-drilling anchor bolt system provides robust geotechnical reinforcement in challenging construction sites, supporting global infrastructure trends and improving safety standards.

SupAnchor's innovative GFRP friction bolt enhances safety and durability in underground engineering and mining with corrosion resistance and no spark risks.

SupAnchor's innovative self drilling anchor system provides critical support in challenging geotechnical conditions for a major European tunneling project, improving efficiency and safety.