In the demanding fields of mining and tunneling, unstable geological conditions often pose significant risks to worker safety and project integrity. SupAnchor's SupHulk friction rock bolt system has emerged as a critical solution, offering robust support through advanced friction-based anchorage. This self drilling anchor system is designed to address challenges such as rock movements and structural weaknesses, ensuring reliable performance in diverse environments. With applications spanning from deep mining operations to large-scale civil engineering tunnels, the SupHulk system exemplifies innovation in geotechnical reinforcement.

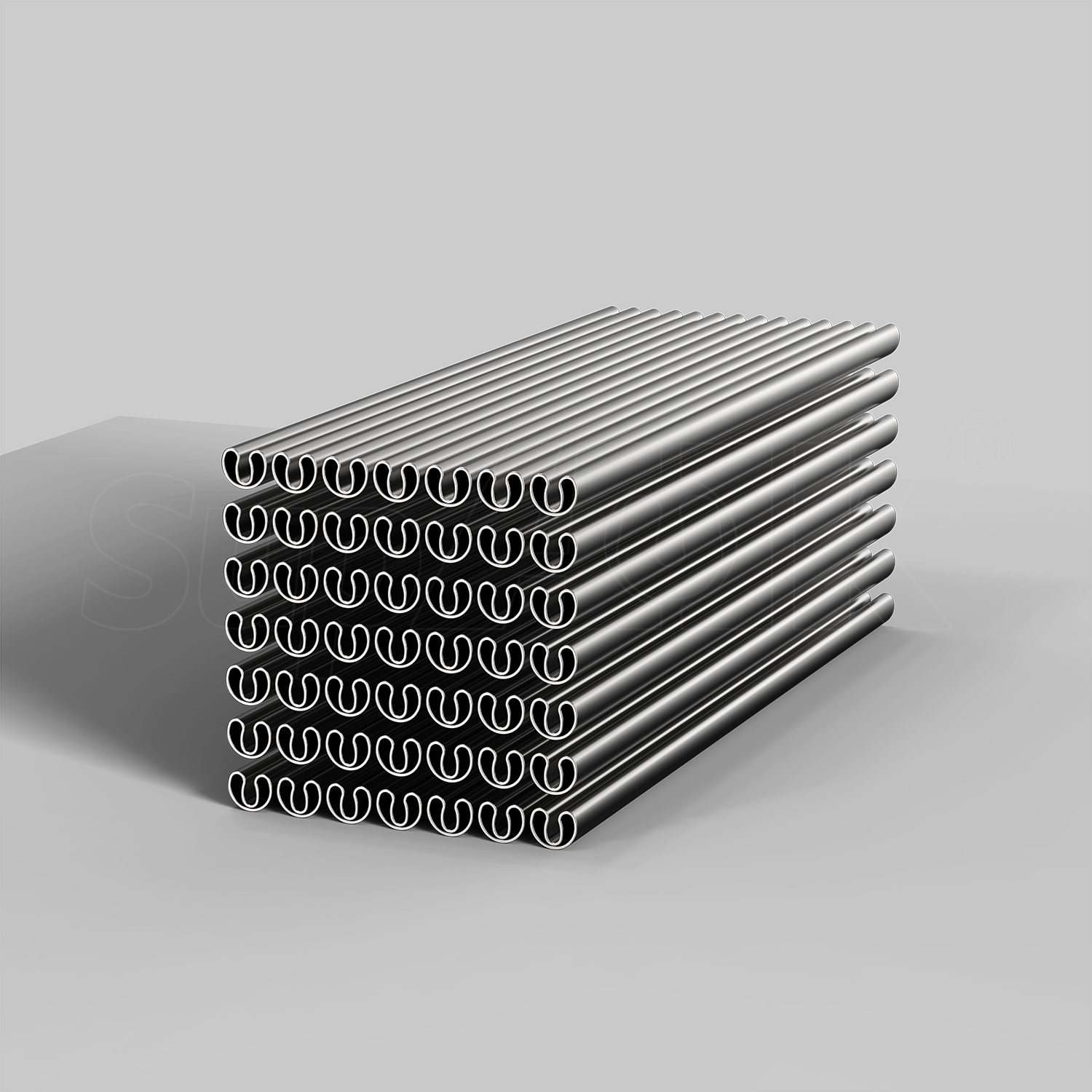

The installation process for the SupHulk rock bolt is straightforward: operators drill a hole, insert the bolt, and inflate it to a predetermined pressure using a specialized system. This simplicity enhances efficiency on-site while maintaining high safety standards. Key technical specifications highlight the system's capability to handle various loads and conditions. For instance, the Premium (PM) series, including models PM12, PM16, and PM24, offers high yield loads and good deformability, allowing immediate absorption of rock movements and distribution of forces along the bolt length. These features are crucial in mitigating risks like rock falls and ensuring long-term stability in mining and tunneling projects.

| Model | Min Breaking Load (kN) | Min Yield Load (kN) | Elongation (%) | Inflation Pressure (bar) | Hole Diameter (mm) |

| PM12 | 110 | 100 | 10 | 300 | 32-39 |

| PM16 | 160 | 130 | 10 | 240 | 43-52 |

| PM24 | 240 | 200 | 10 | 300 | 43-52 |

These parameters enable the SupHulk system to solve common engineering challenges, such as the need for rapid deployment and high load-bearing capacity. The self drilling anchor bolt's ability to form friction and interlocking anchors along the entire borehole length ensures full-column support, adapting to irregularities and bridging gaps in the rock. This makes it an ideal choice for projects requiring quick installation and reliable performance under stress.

The SupHulk rock bolt system is highly versatile, finding use in a wide range of applications. In tunneling, it serves as pattern bolts for systematic anchoring, supporting excavations based on rock mass properties and project scale. For mining, it is commonly employed in roof bolting and hanging wall bolting, providing a rapid and safe solution that enhances operational efficiency. The system's capacity ranges, from 110 kN to 240 kN, allow it to meet the demands of various reinforcement scenarios, including civil engineering projects where geotechnical safety is paramount. Features like the SupHulk net washer and the ability to withstand shear movements further extend its applicability to medium and soft rock conditions, ensuring durability and performance across different environments.

The adoption of SupHulk friction rock bolts contributes significantly to global infrastructure development by improving safety and reducing downtime in mining and tunneling operations. As part of the broader geotechnical reinforcement system, these bolts help prevent accidents and enhance the longevity of structures. SupAnchor, as a leading manufacturer, emphasizes innovation and collaboration in its R&D efforts, holding ISO certifications that underscore its commitment to quality. The company's involvement in international projects demonstrates its role in advancing ground anchor bolt technology, fostering partnerships that drive industry standards forward. This professional and innovative approach ensures that SupAnchor's products, including the self drilling anchor system, remain at the forefront of geotechnical solutions, supporting sustainable development worldwide.

SupAnchor's self-drilling anchor system ensures stable foundations in challenging soil conditions, supporting global infrastructure projects with advanced geotechnical solutions.

SupAnchor's SupCT Bolt System offers high ductility and corrosion resistance for tunneling and mining. Features include factory-preassembled components and optimized grouting design, enhancing safety and efficiency.

SupAnchor's self-drilling anchor bolt system provides robust geotechnical reinforcement in challenging construction sites, supporting global infrastructure trends and improving safety standards.

SupAnchor's innovative GFRP friction bolt enhances safety and durability in underground engineering and mining with corrosion resistance and no spark risks.

SupAnchor's innovative self drilling anchor system provides critical support in challenging geotechnical conditions for a major European tunneling project, improving efficiency and safety.