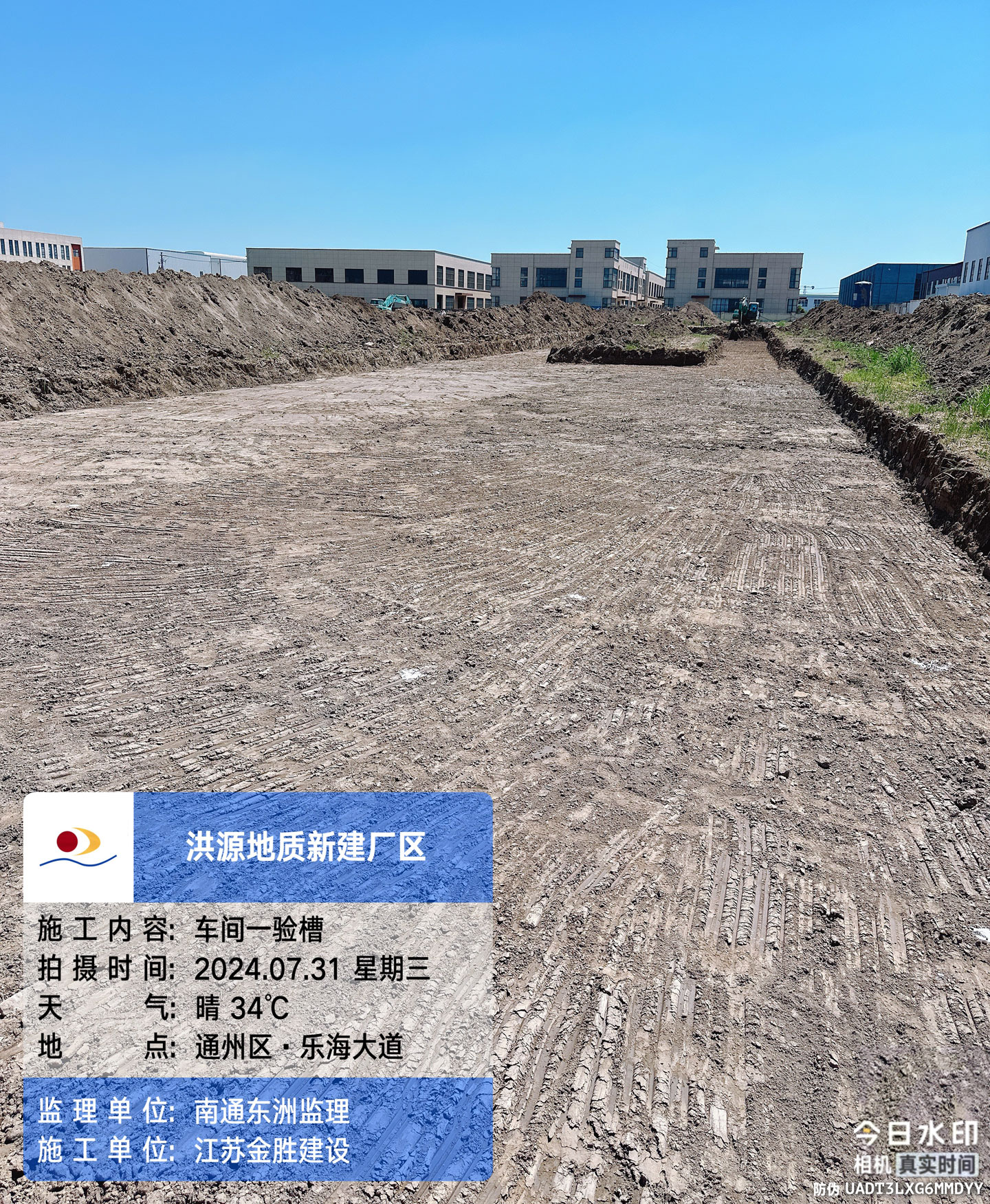

On July 23, 2024, SupAnchor officially began the construction of its Eastern New Plant. Located just 3 kilometers (1.86 miles) east of the old plant, this new facility enjoys a prime geographical position, only 1.5 hours from Shanghai Pudong Airport and 3 hours from the Port of Shanghai, ensuring efficient logistics services for global customers.

The new plant covers an area of 23,500 square meters (about 253,000 square feet), with a building area of 17,000 square meters (about 183,000 square feet). The construction is expected to be completed by mid-2025, with a total investment of 8 million USD.

The new facility is designed to significantly enhance production capacity and automation, featuring the following key production lines:

These new production lines will increase the company’s total production capacity by 30% to 50%, ensuring that SupAnchor can meet the growing demand of the market.

The Eastern New Plant will introduce state-of-the-art production technology and high-speed automation equipment to enhance product quality, production efficiency, and sustainability. The introduction of high-speed anchor rod rolling machines is particularly crucial, as they will significantly shorten production cycles while ensuring precision and consistency in products.

Moreover, the plant will incorporate green and energy-efficient design principles, optimizing energy use and production processes to help reduce carbon emissions, setting a benchmark for green development in the industry.

With 30 years of experience in the self-drilling anchor bolt market, SupAnchor has become the leading exporter in Asia. The construction of the Eastern New Plant is not only a significant milestone in the company's development but also a testament to our unwavering commitment to customers: delivering high-quality, high-performance products and services.

Once operational, the new plant will further solidify SupAnchor’s leadership in the industry, providing even more excellent solutions for global customers. Meanwhile, the old plant will gradually be phased out, making way for the new facility and freeing up more space for future growth.

We look forward to the completion and operation of SupAnchor’s Eastern New Plant, as we move together toward a brighter future!

Industry news on SupAnchor's self drilling anchor bolt application in a complex geology tunnel project, featuring technical parameters and global relevance.

SupAnchor introduces high-performance GFRP reinforcement rebar, offering superior corrosion resistance and tensile strength for diverse construction needs in harsh environments.

SupAnchor's self drilling anchor systems provide critical ground stabilization in a challenging hydropower project, highlighting innovation in geotechnical engineering for infrastructure development.

SupAnchor launches the SupCT Bolt System, a self drilling anchor bolt with high ductility and corrosion resistance, ideal for tunneling and mining projects worldwide.

Report on SupAnchor's application of self drilling anchor bolts for slope stabilization in a major infrastructure project, highlighting technical parameters and industry relevance.