In the demanding environments of soft rock and clay soils, infrastructure projects across Europe and North America face significant geological challenges, including unstable tunnel faces and slope failures. SupAnchor's SupFRP GFRP self drilling anchor system has emerged as a key solution, enabling rapid installation and robust support in applications such as tunneling and slope stabilization. This innovative self drilling anchor bolt combines drilling, grouting, and anchoring into a single process, reducing project timelines and enhancing on-site safety. By addressing common issues like debris accumulation and machinery obstructions, the system supports efficient geotechnical reinforcement in diverse conditions.

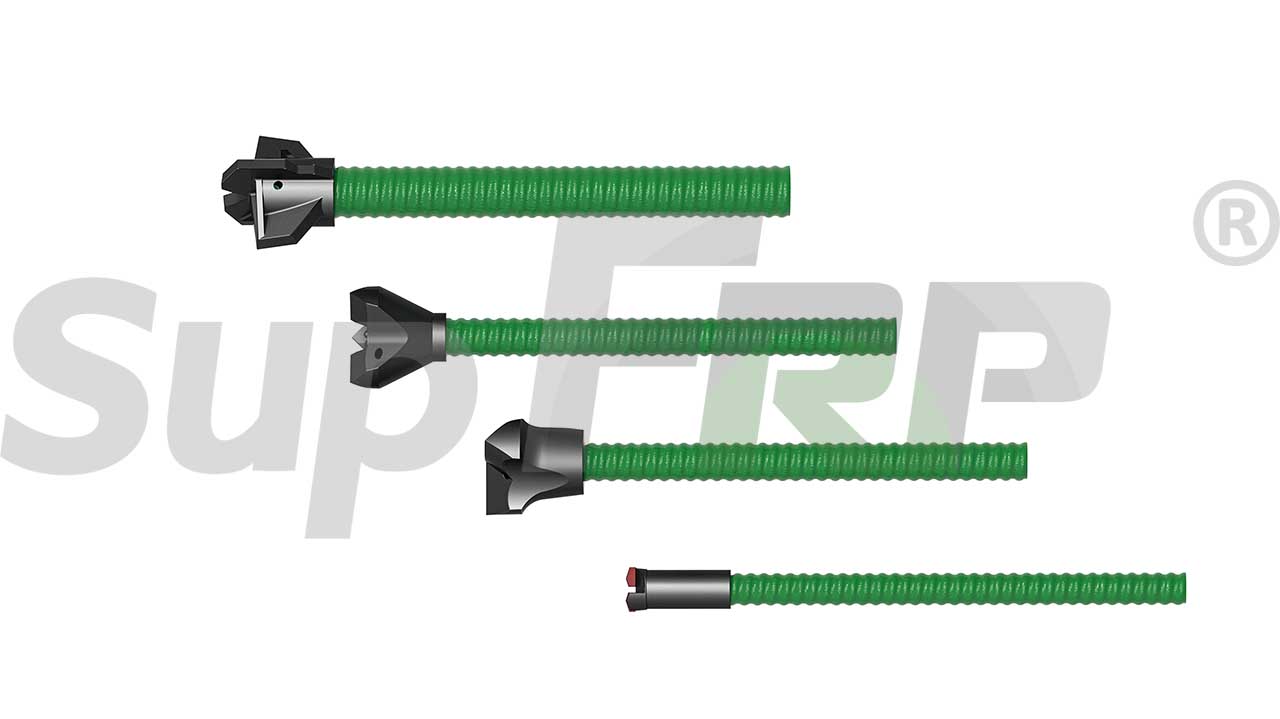

The SupFRP GFRP self drilling anchor system features a central hole that allows for water flushing during drilling, which clears debris and facilitates grouting in soft rock or clay soil. This hollow bar anchor design ensures high torque resistance and easy handling, critical for maintaining stability in dynamic geological settings. Key technical parameters, such as guaranteed tensile load and torsion strength, directly address engineering needs by preventing anchor failure and protecting machinery during installation. For instance, the high tensile E-modulus of 45 GPa across models ensures durability under stress, while the cuttability feature avoids damage during tunnel enlargement. Below is a summary of technical data for the H25S, H28S, H32S, and H38S models, highlighting their role in efficient drill-and-grout bolt applications.

| Model | Outside Diameter (mm) | Internal Diameter (mm) | Guaranteed Tensile Load (kN) | Torsion Strength (Nm) | Weight (kg/m) |

|---|---|---|---|---|---|

| H25S | 25 | 12 | 220 | 180 | 0.63 |

| H28S | 28 | 14 | 280 | 250 | 0.86 |

| H32S | 32 | 15 | 365 | 360 | 0.99 |

| H38S | 38 | 20 | 490 | 450 | 1.33 |

These specifications enable the self drilling anchor system to handle high end loading and permanent applications, making it ideal for reinforcing tunnel faces and stabilizing slopes. The ISO standard thread profile ensures compatibility with global equipment, while the lightweight design simplifies logistics and reduces labor costs. By integrating these features, SupAnchor's geotechnical reinforcement system minimizes risks in unstable ground, supporting safer and more efficient construction practices.

The versatility of the self drilling anchor bolt extends to various critical applications, enhancing safety and efficiency in infrastructure projects. Key uses include:

This hollow bar anchor system is particularly effective in projects requiring quick deployment, such as emergency repairs or urban development in geologically sensitive areas. For example, in European tunneling projects, the drill-and-grout bolt has reduced installation time by up to 30%, according to field reports, highlighting its value in time-critical scenarios.

The adoption of SupAnchor's self drilling anchor system aligns with global trends in sustainable infrastructure and geotechnical safety. In regions prone to soil instability, such as parts of the Americas and Europe, this technology supports resilient tunneling and mining operations, reducing accident rates and project overruns. The geotechnical reinforcement system contributes to international standards by offering corrosion-resistant GFRP materials, which extend service life and lower maintenance costs. As infrastructure demands grow, innovations like this drill-and-grout bolt play a crucial role in enabling safer, faster construction methods, ultimately supporting economic development and public safety worldwide.

SupAnchor has built a reputation for professionalism and innovation through extensive research and development, resulting in products like the GFRP self drilling anchor bolt. With ISO certifications ensuring quality and consistency, the company collaborates with global partners on projects ranging from urban tunnels to remote slope stabilizations. This collaborative approach fosters knowledge sharing and adapts solutions to local geological challenges, reinforcing SupAnchor's role as a leader in the geotechnical reinforcement system market. By prioritizing R&D and customer feedback, the brand continues to advance technologies that address evolving industry needs, cementing its influence in the self drilling anchor system sector.

SupAnchor's self-drilling anchor system provides robust geotechnical reinforcement for slope stabilization and foundation support in challenging projects, ensuring safety and efficiency.

SupAnchor's SupHulk friction rock bolt system offers high load capacity and immediate support for rock reinforcement in mining and tunneling, enhancing geotechnical safety with innovative self drilling anchor technology.

SupAnchor's innovative self drilling anchor bolt system provides robust geotechnical reinforcement in challenging infrastructure projects, ensuring safety and efficiency.

SupAnchor introduces the SupUTS self-drilling hollow anchor, offering superior load-bearing and corrosion resistance for demanding infrastructure projects, improving efficiency in unstable soils.

An in-depth look at how SupAnchor's self drilling anchor bolts are revolutionizing geotechnical safety and efficiency in challenging European infrastructure developments.