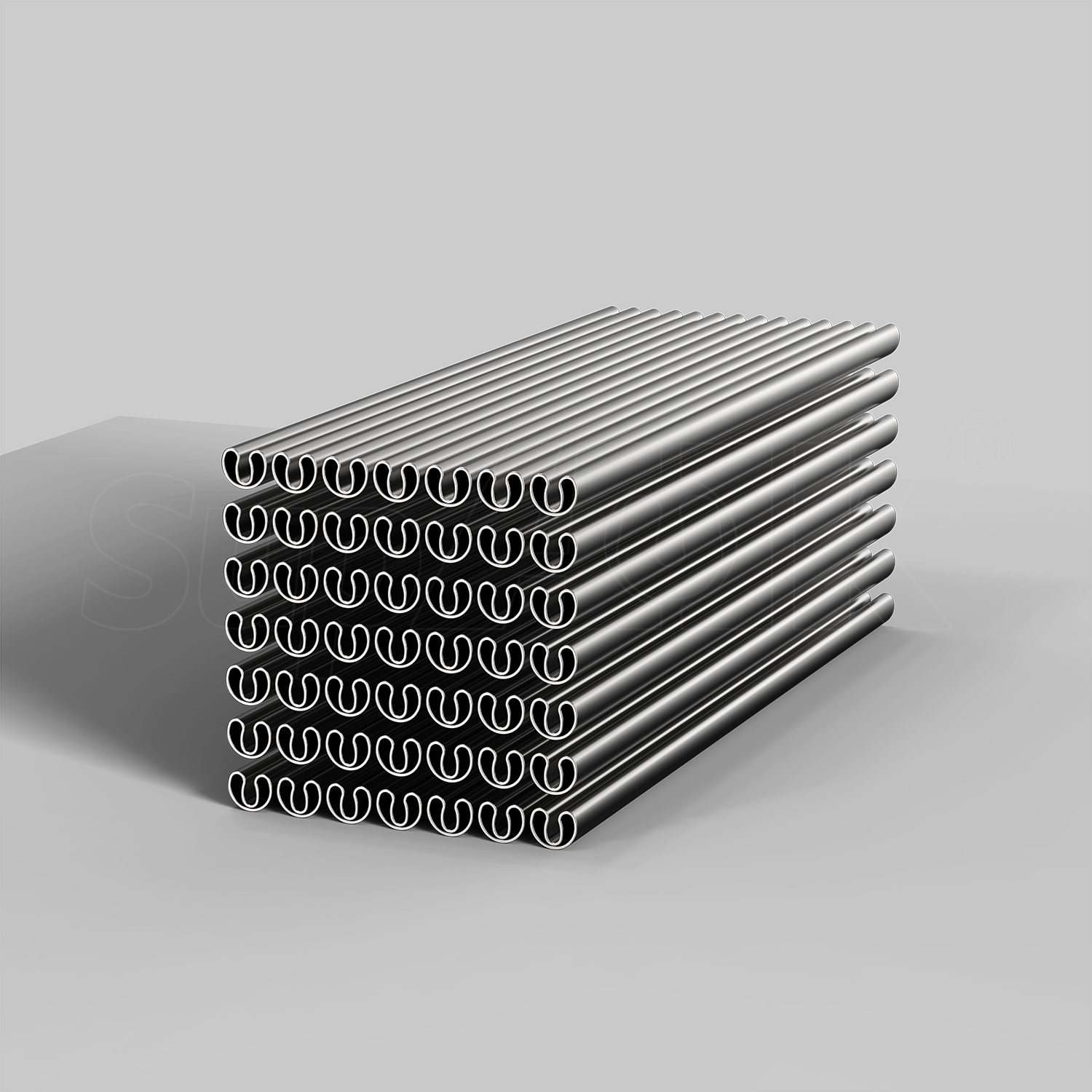

In the demanding world of modern infrastructure, mining and tunneling projects face increasing challenges from unstable geological conditions, requiring robust and reliable support systems. SupAnchor, a leading manufacturer in the geotechnical reinforcement industry, has responded with the SupHulk Friction Rock Bolt System, a self-drilling anchor bolt designed to provide immediate and durable support. This innovative system addresses critical needs in both mining and civil engineering, enhancing safety and efficiency on a global scale.

The SupHulk system leverages a simple yet effective installation process: operators drill a hole, insert the bolt, and inflate it to a pre-determined pressure using a specialized pump. This friction-based anchoring mechanism allows the bolt to bear full loads immediately after installation, absorbing rock movements and distributing force along its entire length. Key parameters from the Premium (PM) series highlight its performance: for instance, the PM24 model offers a minimum breaking load of 240 kN and a yield load of 200 kN, with an inflation pressure of 300 bar. These specs ensure the system can handle low to medium stress conditions in tunneling and mining, providing stiff support with high deformability.

| Model | Min Breaking Load (kN) | Min Yield Load (kN) | Inflation Pressure (bar) | Hole Diameter Range (mm) |

|---|---|---|---|---|

| PM12 | 110 | 100 | 300 | 32-39 |

| PM16 | 160 | 130 | 240 | 43-52 |

| PM24 | 240 | 200 | 300 | 43-52 |

The system's adaptability is further demonstrated by its ability to bridge gaps in rock, withstand shear movements, and conform to borehole irregularities. With a 50 cm inflated section generating 100 kN of friction, it offers full-column support, making it a versatile geotechnical reinforcement system for various applications. This self-drilling anchor bolt minimizes installation time and ensures quality through automated pressure control, reducing human error and enhancing project timelines.

SupHulk rock bolts are highly versatile, finding use in numerous tunneling and mining systems worldwide. In tunneling, they serve as pattern bolts for excavation support, with bolting patterns tailored to rock mass properties and project scale. For mining, applications include roof bolting and hanging wall bolting, where the system's rapid deployment and high performance improve safety and operational efficiency. This hollow bar anchor technology is suitable for both mining and civil engineering projects, such as urban tunnels and infrastructure developments, contributing to global geotechnical safety standards.

The system's capacity ranges—from 110 kN to 240 kN—allow it to meet diverse reinforcement needs, ensuring reliable performance in medium to soft rocks. By integrating this drill-and-grout bolt alternative, industries can achieve cost savings and reduced environmental impact through efficient material use and minimized downtime.

SupAnchor's commitment to innovation is evident in the SupHulk system, developed through extensive R&D and backed by ISO certifications. The brand emphasizes a professional, innovative, and collaborative approach, working on global projects that span from European tunneling ventures to American mining operations. As a soil nail system manufacturer and ground anchor bolt factory, SupAnchor leverages its expertise to deliver high-quality self-drilling anchor systems that meet international standards. The company's focus on sustainability and safety aligns with modern engineering demands, positioning it as a key player in the geotechnical reinforcement market.

Looking ahead, SupAnchor continues to expand its portfolio, driving advancements in self-drilling anchor technology to support the growing needs of global infrastructure. The SupHulk Friction Rock Bolt System exemplifies this progress, offering a reliable solution for engineers and project managers seeking to enhance geotechnical reinforcement in complex environments.

A report on how SupAnchor's self drilling anchor bolts solve geotechnical challenges in a major tunneling project, featuring technical specs and global industry relevance.

SupAnchor® GFRP SDA Bolt combines drilling, grouting, and anchoring for efficient geotechnical reinforcement, supporting infrastructure projects globally with high torque resistance and easy handling.

An industry report on SupAnchor's self drilling anchor bolts providing geotechnical reinforcement in a challenging Alpine slope project, highlighting technical specs and global trends.

SupAnchor introduces the SupCT Bolt System, a high-performance self-drilling anchor system with duplex corrosion protection and versatile applications in mining, tunneling, and infrastructure projects.

Industry report on SupAnchor's self drilling anchor system improving stability in challenging tunneling projects, highlighting technical specs and global trends.