In the demanding field of geotechnical engineering, projects across Europe and North America frequently encounter complex geological conditions such as unstable slopes, soft rock formations, and confined ground spaces. These challenges necessitate robust and innovative solutions to ensure structural integrity and safety. SupAnchor, a prominent manufacturer in the geotechnical reinforcement system sector, has responded with the introduction of the SupFRP® GFRP Hollow Injection Bolt. This product is designed to streamline installation processes while providing durable support, making it a critical tool for modern infrastructure development.

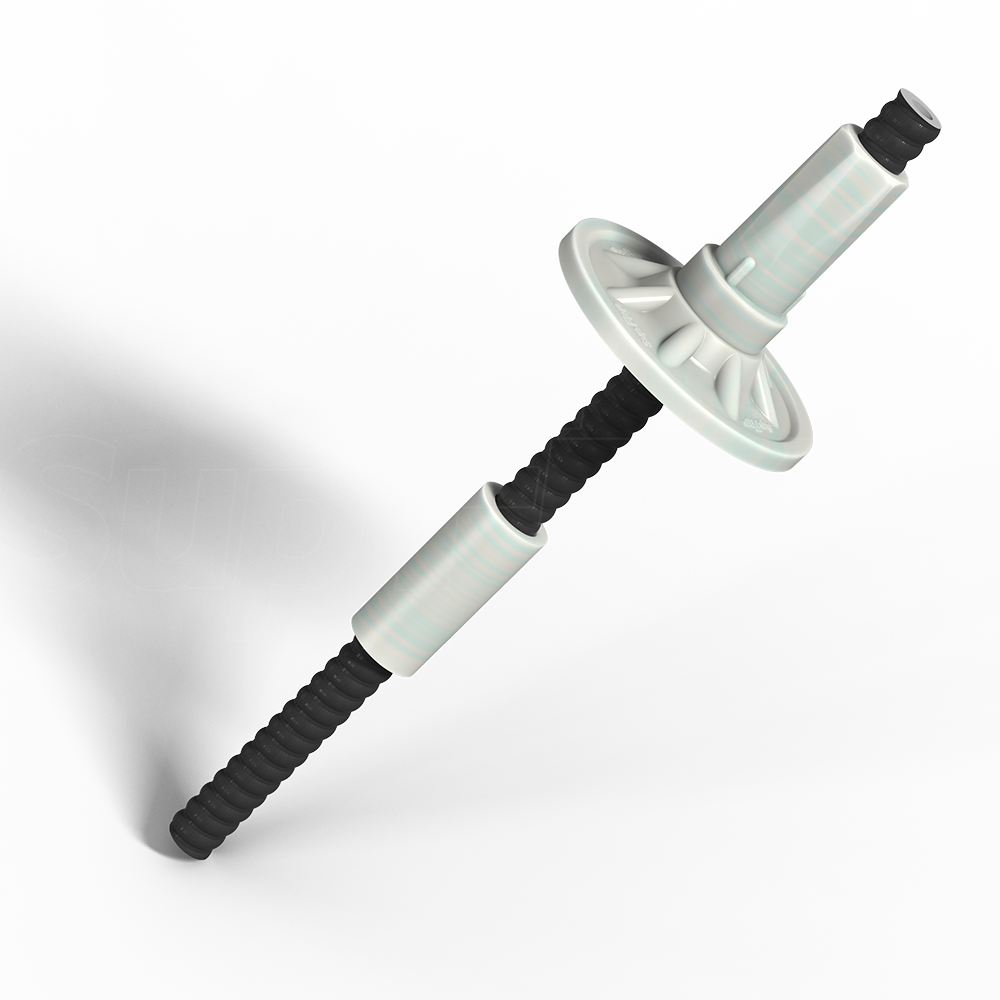

The SupFRP® GFRP Hollow Injection Bolt stands out as a core component of SupAnchor's SupFRP series, engineered to integrate the functions of a rock bolt and injection system. After completing injection work, the bolt remains embedded in the borehole, collaborating with end plates and nuts to bear substantial loads. This self drilling anchor system leverages high injection pressure to achieve full grouting, which enhances bonding with all grouting materials and significantly improves project quality. Key advantages include high pressure resistance, low weight for easy handling, high tensile load capacity, cuttability for customized lengths, high corrosion resistance, and excellent bond force. These features address common engineering hurdles such as material degradation and installation inefficiencies, particularly in harsh environments.

To meet diverse project requirements, SupAnchor offers multiple models with varying specifications. Below is a detailed technical overview showcasing the adaptability and performance of this hollow bar anchor:

| Model | Outside Diameter (mm) | Guaranteed Tensile Load (kN) | Pressure Resistance (MPa) | Weight (kg/m) | Length Options (m) |

|---|---|---|---|---|---|

| H25/220 | 25 | 220 | 5 | 0.64 | 2 to 11 |

| H28/320 | 28 | 320 | 5 | 0.88 | 2 to 11 |

| H32/360 | 32 | 360 | 5 | 1.20 | 2 to 11 |

| H38/490 | 38 | 490 | 5 | 1.5 | 2 to 11 |

| H22/230 | 22 | 230 | 18 | 0.58 | 2 to 11 |

| H25/300 | 25 | 300 | 30 | 0.79 | 2 to 11 |

This drill-and-grout bolt system excels in scenarios requiring high tensile strength and corrosion resistance, such as permanent installations in coastal or industrial areas. The use of Glass Fiber Reinforced Polymer (GFRP) material ensures longevity, reducing maintenance costs and enhancing sustainability in geotechnical projects.

The SupAnchor GFRP Hollow Injection Bolt is versatile, catering to numerous geotechnical challenges. Key applications include slope stabilization, where it prevents soil erosion and landslides; TBM face support, providing stability during tunnel boring machine operations; forepoling for temporary ground support in excavation; confined ground conditions in urban developments; stabilization of soft rock in mining operations; and permanent applications in infrastructure like bridges and retaining walls. This self drilling anchor bolt system allows for rapid deployment, minimizing downtime and improving safety on-site. For instance, in slope stabilization projects, the high bond force with grouting materials ensures long-term reliability, while in tunneling, the pressure resistance capabilities support complex geological formations.

The introduction of this advanced geotechnical reinforcement system aligns with global trends in infrastructure development, where safety, efficiency, and environmental considerations are paramount. In sectors like tunneling, mining, and transportation, the bolt's high performance contributes to reduced accident rates and enhanced project timelines. By offering a lightweight yet durable solution, SupAnchor addresses the growing demand for innovative materials in construction, supporting sustainable practices and economic growth. This hollow bar anchor not only meets current engineering standards but also sets a benchmark for future innovations in ground anchoring technologies.

SupAnchor has built a reputation for professionalism, innovation, and collaboration through extensive R&D efforts and adherence to international quality standards, including ISO certifications. The company's global projects, from European railways to American highways, demonstrate its commitment to delivering reliable solutions. The SupFRP® series, including this self drilling anchor system, reflects SupAnchor's focus on customer-centric design and technological advancement. By fostering partnerships with engineering teams worldwide, SupAnchor ensures that its products, such as this ground anchor bolt, are tailored to real-world needs, reinforcing its position as a leader in the soil nail system manufacturing industry.

In summary, the SupAnchor GFRP Hollow Injection Bolt represents a significant leap forward in geotechnical engineering, combining technical prowess with practical adaptability. As infrastructure projects become increasingly complex, this product offers a reliable and efficient solution, underscoring SupAnchor's dedication to enhancing global safety and innovation.

SupAnchor's self drilling anchor system addresses complex geology in a large-scale project, highlighting innovation in geotechnical engineering for global infrastructure trends.

SupAnchor's Sup2000 and Sup5000 grout pumps, with high delivery rates and robust design, optimize injection work in tunneling, civil engineering, and mining applications worldwide.

A large-scale tunnel project in Europe utilizes SupAnchor's self-drilling anchor bolts to overcome complex geology, improving infrastructure safety and efficiency.

SupAnchor introduces the GFRP SDA Bolt, an innovative self drilling anchor system that integrates drilling, grouting, and anchoring for fast installation in soft rock and clay soil, improving safety and efficiency in global infrastructure projects.

SupAnchor's advanced self drilling anchor bolt system provides critical support in a challenging Alpine tunneling project, showcasing innovation in geotechnical reinforcement systems for global infrastructure.