In the demanding fields of mining and tunneling, geological instability poses significant challenges, requiring robust support systems to ensure safety and efficiency. SupAnchor, a leading manufacturer, addresses these issues with its innovative SupHulk friction rock bolt system, designed for immediate load-bearing and adaptability in various rock conditions. This self drilling anchor system is pivotal in projects across Europe and America, where infrastructure demands high-performance geotechnical reinforcement.

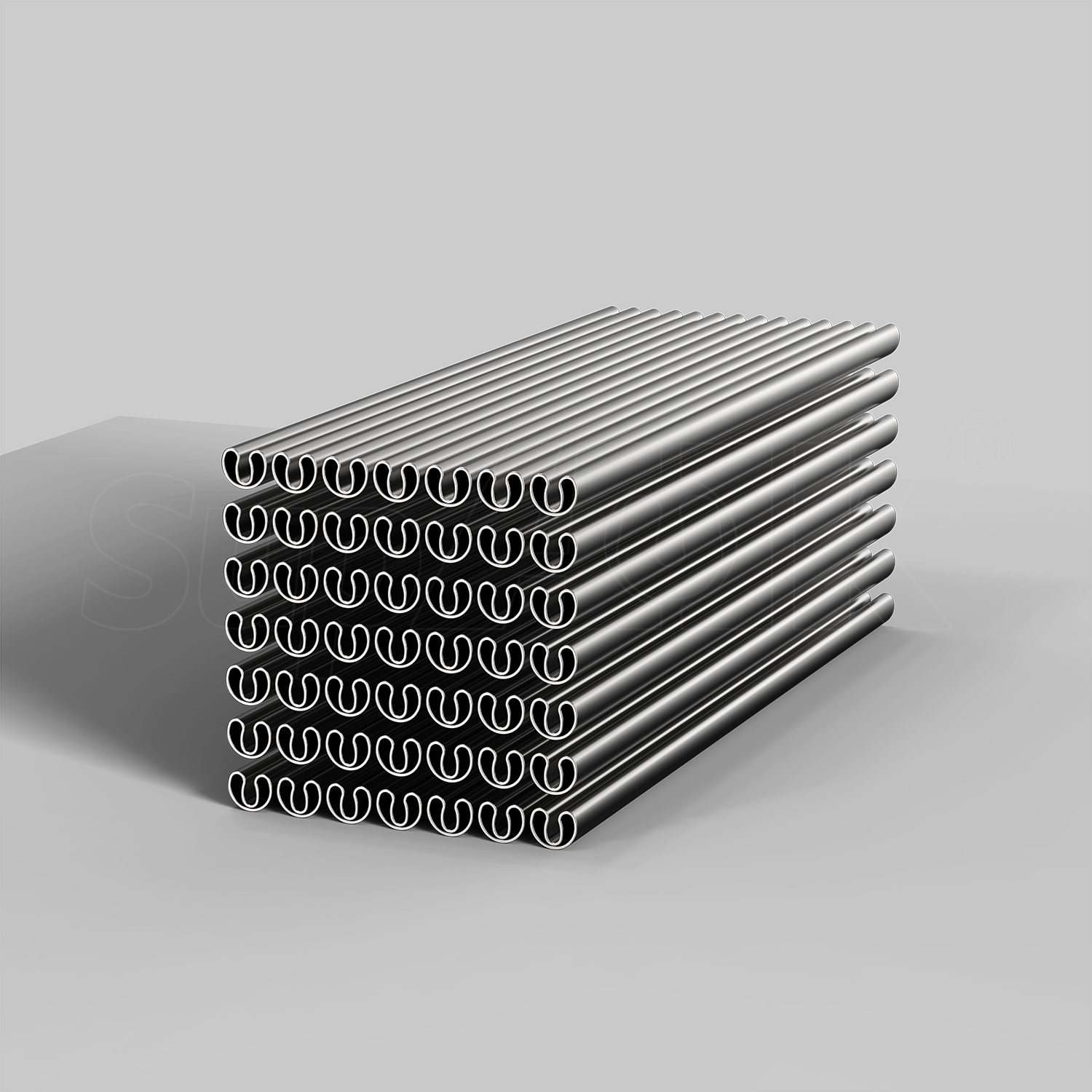

The SupHulk system simplifies installation: operators drill a hole, insert the bolt, and inflate it to a preset pressure using a specialized pump, which automatically stops at the recommended level. This process ensures quality and allows for easy pull-testing. Key parameters include high yield loads and deformability, with the Premium line (PM) series offering models like PM12, PM16, and PM24. Below is a summary of critical specs:

| Parameter | PM12 | PM16 | PM24 |

|---|---|---|---|

| Min Breaking Load (kN) | 110 | 160 | 240 |

| Min Yield Load (kN) | 100 | 130 | 200 |

| Elongation (%) | 10 | 10 | 10 |

| Inflation Pressure (bar) | 300 | 240 | 300 |

These specifications enable the SupHulk bolt to handle shear movements and provide full-column support, solving engineering challenges like rock movement absorption and irregular borehole adaptation. The system's friction-based anchorage distributes force evenly, making it ideal for low to medium stress conditions in mining and tunneling.

The SupHulk rock bolt is highly versatile, used in pattern bolting for tunneling excavations and roof or hanging wall bolting in mining. Its capacity ranges from 110 kN to 240 kN allow it to suit most reinforcement needs. Key applications include:

This self drilling anchor bolt system bridges gaps in rock and allows significant shear movements, ensuring reliability in diverse environments from soft to hard rock formations.

SupHulk contributes to global infrastructure by improving safety and efficiency in geotechnical reinforcement systems. Its use in mining and tunneling reduces risks of collapses and enhances project timelines. The system's innovation supports sustainable development in resource extraction and urban expansion, aligning with international safety standards. SupAnchor's commitment to quality, backed by ISO certifications, ensures that products like the hollow bar anchor meet rigorous demands, fostering trust in European and American markets.

SupAnchor emphasizes professionalism, innovation, and collaboration through continuous R&D. The company's global projects demonstrate its expertise in developing advanced drill-and-grout bolt technologies. By focusing on customer needs and environmental adaptability, SupAnchor reinforces its position as a leader in the soil nail system manufacturer space, driving progress in ground anchor bolt factory operations worldwide.

A report on SupAnchor's self drilling anchor bolts used in a challenging tunneling project, highlighting technical specs, industry trends, and innovation in geotechnical reinforcement.

SupAnchor's new GFRP solid bolt provides high tensile strength and corrosion resistance, ideal for slope stabilization and tunnel support in harsh environments, improving safety and durability.

An in-depth look at SupAnchor's self drilling anchor bolts used in a challenging subway project, highlighting technical specs, industry trends, and innovation in geotechnical reinforcement.

SupAnchor introduces the Grade 75 self-drilling hollow anchor, offering high-strength steel and efficient 3-in-1 design for demanding geotechnical reinforcement in infrastructure and tunneling.

SupAnchor's T thread self-drilling hollow anchor integrates drilling and grouting, improving efficiency and safety in tunneling, slope stabilization, and foundation projects with robust anti-corrosion options.