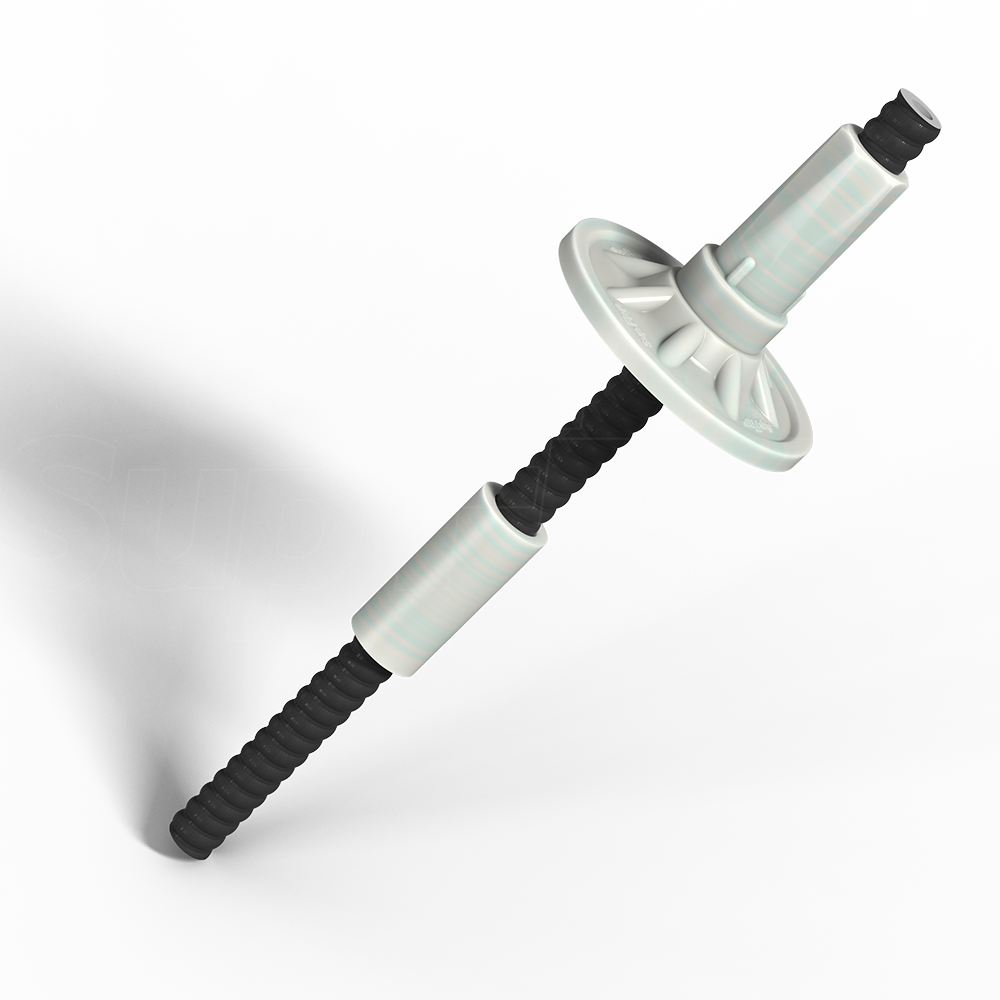

In regions with complex geological conditions, such as unstable slopes and soft rock formations, engineers face significant challenges in ensuring structural integrity and safety. SupAnchor's GFRP Hollow Injection Bolt, a key component of their self drilling anchor system, addresses these issues by combining robust design with advanced materials. This product is increasingly being adopted in European and American infrastructure projects, where its ability to handle high loads and resist corrosion makes it a reliable choice for demanding environments. The bolt's integration of drilling and grouting functions streamlines construction processes, reducing time and costs while enhancing overall project quality.

The SupAnchor GFRP Hollow Injection Bolt is engineered to meet the rigorous demands of geotechnical applications. With features like high tensile load, pressure resistance, and lightweight construction, it offers substantial benefits on-site. For instance, in tunneling projects, the bolt's hollow design allows for efficient injection of grouting materials, ensuring full bonding and stability. Key parameters from the product line demonstrate its versatility and strength, making it suitable for various ground conditions. The following table summarizes the technical data for different models, highlighting how each specification contributes to solving engineering challenges such as load distribution and environmental durability.

| Model | Outside Diameter (mm) | Internal Diameter (mm) | Guaranteed Tensile Load (kN) | Pressure Resistance (MPa) | Weight (kg/m) |

|---|---|---|---|---|---|

| H25/220 | 25 | 12 | 220 | 5 | 0.64 |

| H28/320 | 28 | 12 | 320 | 5 | 0.88 |

| H32/360 | 32 | 15 | 360 | 5 | 1.20 |

| H38/490 | 38 | 20 | 490 | 5 | 1.5 |

| H22/230 | 22 | 8 | 230 | 18 | 0.58 |

| H25/300 | 25 | 8 | 300 | 30 | 0.79 |

These specifications, such as the high tensile loads up to 490 kN and pressure resistance up to 30 MPa, enable the bolt to withstand extreme forces in applications like slope stabilization and TBM face support. The lightweight nature, with weights as low as 0.58 kg/m, facilitates easy handling and installation, reducing labor costs and improving efficiency. Moreover, the cuttability and high corrosion resistance ensure long-term performance in harsh environments, addressing common issues in geotechnical engineering where moisture and chemical exposure can compromise structural elements. By providing a reliable geotechnical reinforcement system, SupAnchor's hollow bar anchor minimizes risks and enhances safety across various projects.

The versatility of the SupAnchor self drilling anchor bolt is evident in its wide range of applications. Key uses include slope stabilization, where the bolt's high bond force and full grouting capability prevent soil erosion and landslides. In tunneling and mining, it serves as a critical component for TBM face support and forepoling, ensuring stability in confined ground conditions. The product's adaptability to soft rock stabilization and permanent installations makes it a go-to solution for engineers seeking durable and efficient reinforcement. For example, in European infrastructure projects, the drill-and-grout bolt has been deployed to secure excavation sites, demonstrating its value in reducing project timelines and enhancing safety standards. This geotechnical reinforcement system not only meets current engineering needs but also anticipates future challenges in urban development and environmental conservation.

The introduction of SupAnchor's GFRP Hollow Injection Bolt has significant implications for the global infrastructure sector. As urbanization accelerates and climate change intensifies geological risks, reliable reinforcement systems are essential for sustainable development. This product contributes to safer tunneling operations, reduced maintenance in mining, and improved resilience in slope stabilization projects. By leveraging advanced materials like GFRP, which offers high strength-to-weight ratios and corrosion resistance, the hollow bar anchor supports long-term economic and environmental goals. In regions prone to earthquakes or heavy rainfall, the self drilling anchor system provides a proactive approach to disaster mitigation, aligning with international safety standards and fostering collaboration among stakeholders in construction and engineering.

SupAnchor has established itself as a leader in geotechnical solutions through continuous research and development. The company's commitment to innovation is reflected in products like the GFRP Hollow Injection Bolt, which underwent rigorous testing to achieve high performance metrics. With ISO certifications ensuring quality control, SupAnchor has successfully implemented this technology in global projects, from European tunneling initiatives to American mining operations. The brand's professional approach emphasizes collaboration with engineers and contractors, ensuring that the drill-and-grout bolt meets specific site requirements. By focusing on R&D and customer-centric solutions, SupAnchor reinforces its message of professionalism, innovation, and teamwork, driving advancements in the geotechnical reinforcement system market and setting new benchmarks for industry excellence.

In conclusion, SupAnchor's GFRP Hollow Injection Bolt represents a significant leap forward in geotechnical engineering, offering a blend of technical prowess and practical adaptability. As infrastructure demands grow, this self drilling anchor bolt will play a crucial role in enhancing safety and efficiency worldwide, supported by SupAnchor's unwavering dedication to quality and innovation.

A report on how SupAnchor's self drilling anchor bolts solve geotechnical challenges in a major tunneling project, featuring technical specs and global industry relevance.

SupAnchor® GFRP SDA Bolt combines drilling, grouting, and anchoring for efficient geotechnical reinforcement, supporting infrastructure projects globally with high torque resistance and easy handling.

An industry report on SupAnchor's self drilling anchor bolts providing geotechnical reinforcement in a challenging Alpine slope project, highlighting technical specs and global trends.

SupAnchor introduces the SupCT Bolt System, a high-performance self-drilling anchor system with duplex corrosion protection and versatile applications in mining, tunneling, and infrastructure projects.

Industry report on SupAnchor's self drilling anchor system improving stability in challenging tunneling projects, highlighting technical specs and global trends.