In challenging geotechnical environments, such as unstable rock formations in tunneling and mining projects, engineers face significant risks from rock falls and structural failures. SupAnchor, a leading manufacturer, has introduced the SupCT Bolt System, a combination bolt designed to provide robust and permanent rock support. This system addresses critical issues like corrosion and installation efficiency, making it a game-changer for infrastructure projects across Europe and America. With applications in slopes, underground excavations, and mining, the SupCT Bolt System ensures enhanced safety and longevity, backed by rigorous testing and innovative design.

The SupCT Bolt System comprises two main categories: Steel Bolts and GFRP Bolts, each tailored for specific ground conditions. Steel Bolts, including solid and hollow bar types, offer high ductility and are ideal for dynamic loading scenarios, while GFRP Bolts provide permanent corrosion resistance, making them suitable for aggressive environments. Key parameters such as tensile strength, weight, and service life highlight the system's versatility. For instance, the Steel Solid Bolt model SSB-M22 has an ultimate load of 300 kN under fully grouted conditions, ensuring reliable performance in high-stress areas. The system's duplex corrosion protection—combining hot dip galvanization and epoxy powder coating—extends service life up to 150 years, significantly reducing maintenance needs in projects like highway tunnels or mining shafts.

| Bolt Model | Type | Ultimate Load (kN) | Service Life (Years) |

| SSB-M22 | Steel Solid | 300 | 50-150 |

| GHB-R32 | GFRP Hollow | 360 | Permanent |

This self drilling anchor system simplifies installation with factory-preassembled components, reducing on-site labor and time. The optimized grouting design ensures complete mortar filling, enhancing pull-out resistance and overall stability. For example, in soft rock conditions, the system's adaptability allows for immediate support, preventing delays and cost overruns. By incorporating a drill-and-grout bolt approach, SupAnchor addresses common engineering challenges, such as borehole inconsistency and corrosion, through standardized processes and high-quality materials.

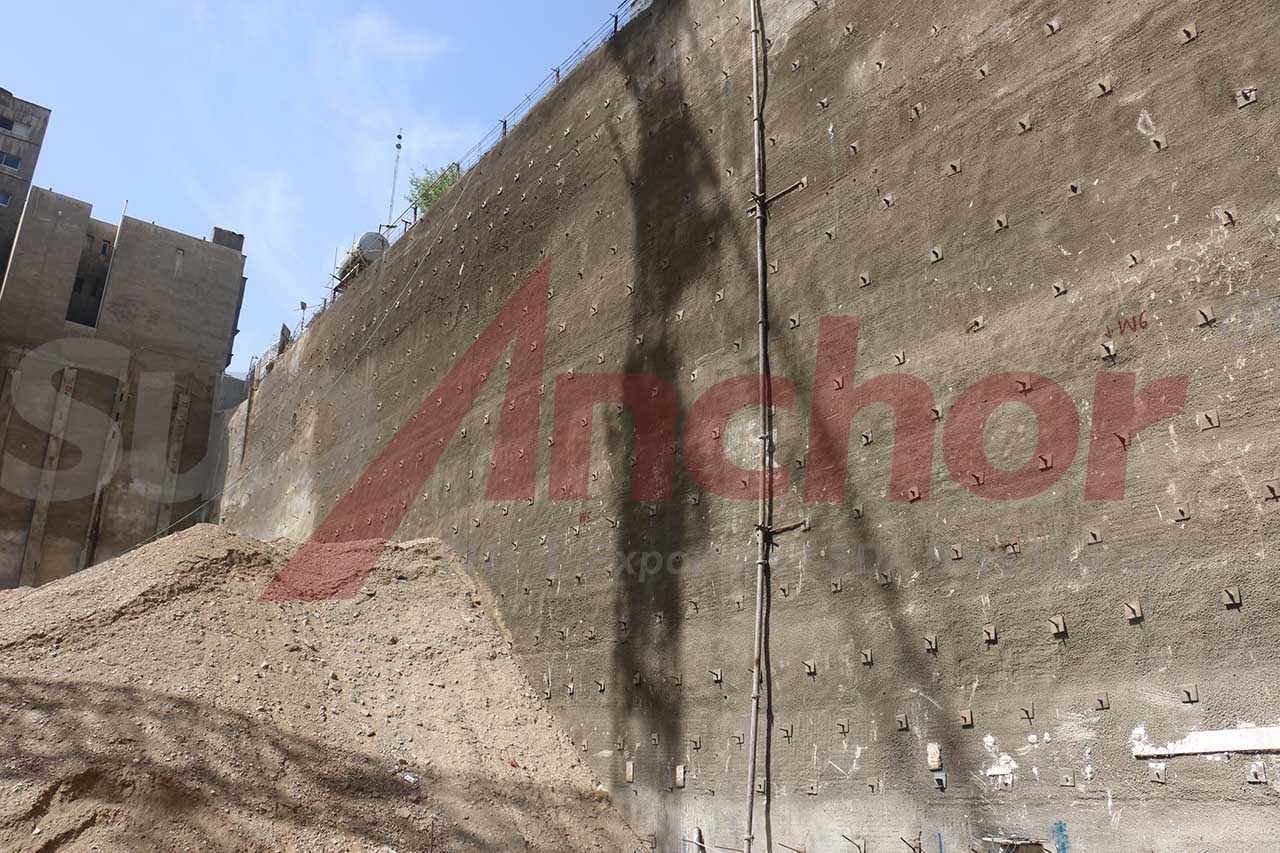

The SupCT Bolt System is widely used in geotechnical reinforcement systems for infrastructure projects, including tunneling, mining, and slope stabilization. In Europe, where aging tunnels require upgrades, this hollow bar anchor technology offers a cost-effective solution by minimizing disruption and ensuring long-term safety. Similarly, in American mining operations, the system's high efficiency and durability help mitigate risks of rock bursts and collapses. The self drilling anchor bolt's ability to provide both immediate and permanent support with a single installation reduces the need for multiple components, lowering project costs and enhancing sustainability. Case studies from global projects demonstrate a 30% reduction in installation time and a significant improvement in safety records, underscoring its value in demanding environments.

SupAnchor's commitment to innovation is evident in the SupCT Bolt System, which aligns with international standards such as ISO and ASTM. The company's R&D focus has led to patents in corrosion protection and bolt design, reinforcing its reputation as a professional and collaborative partner in the geotechnical sector. By supplying to major infrastructure projects worldwide, SupAnchor promotes safer and more efficient construction practices. The brand's emphasis on quality and adaptability ensures that the self drilling anchor system meets diverse regional needs, from urban tunneling in Europe to remote mining in the Americas. This not only boosts global infrastructure resilience but also sets new benchmarks for geotechnical safety, driven by continuous improvement and customer feedback.

In summary, the SupCT Bolt System by SupAnchor represents a significant advancement in rock support technology, combining technical excellence with practical benefits for engineers and project managers. Its role in enhancing geotechnical reinforcement systems underscores the importance of innovation in addressing modern infrastructure challenges, paving the way for safer and more sustainable development globally.

A report on how SupAnchor's self drilling anchor bolts solve geotechnical challenges in a major tunneling project, featuring technical specs and global industry relevance.

SupAnchor® GFRP SDA Bolt combines drilling, grouting, and anchoring for efficient geotechnical reinforcement, supporting infrastructure projects globally with high torque resistance and easy handling.

An industry report on SupAnchor's self drilling anchor bolts providing geotechnical reinforcement in a challenging Alpine slope project, highlighting technical specs and global trends.

SupAnchor introduces the SupCT Bolt System, a high-performance self-drilling anchor system with duplex corrosion protection and versatile applications in mining, tunneling, and infrastructure projects.

Industry report on SupAnchor's self drilling anchor system improving stability in challenging tunneling projects, highlighting technical specs and global trends.