In the heart of the Swiss Alps, a critical infrastructure project aimed at expanding the Gotthard Base Tunnel has successfully navigated complex geological hurdles, thanks to the deployment of advanced self drilling anchor systems from SupAnchor. This initiative, part of Europe's broader push for enhanced transportation networks, faced unstable rock formations and high groundwater pressures, necessitating robust geotechnical reinforcement to prevent collapses and ensure worker safety. SupAnchor's role in providing reliable foundation support and slope stabilization has been pivotal, aligning with global trends in infrastructure development and geotechnical safety.

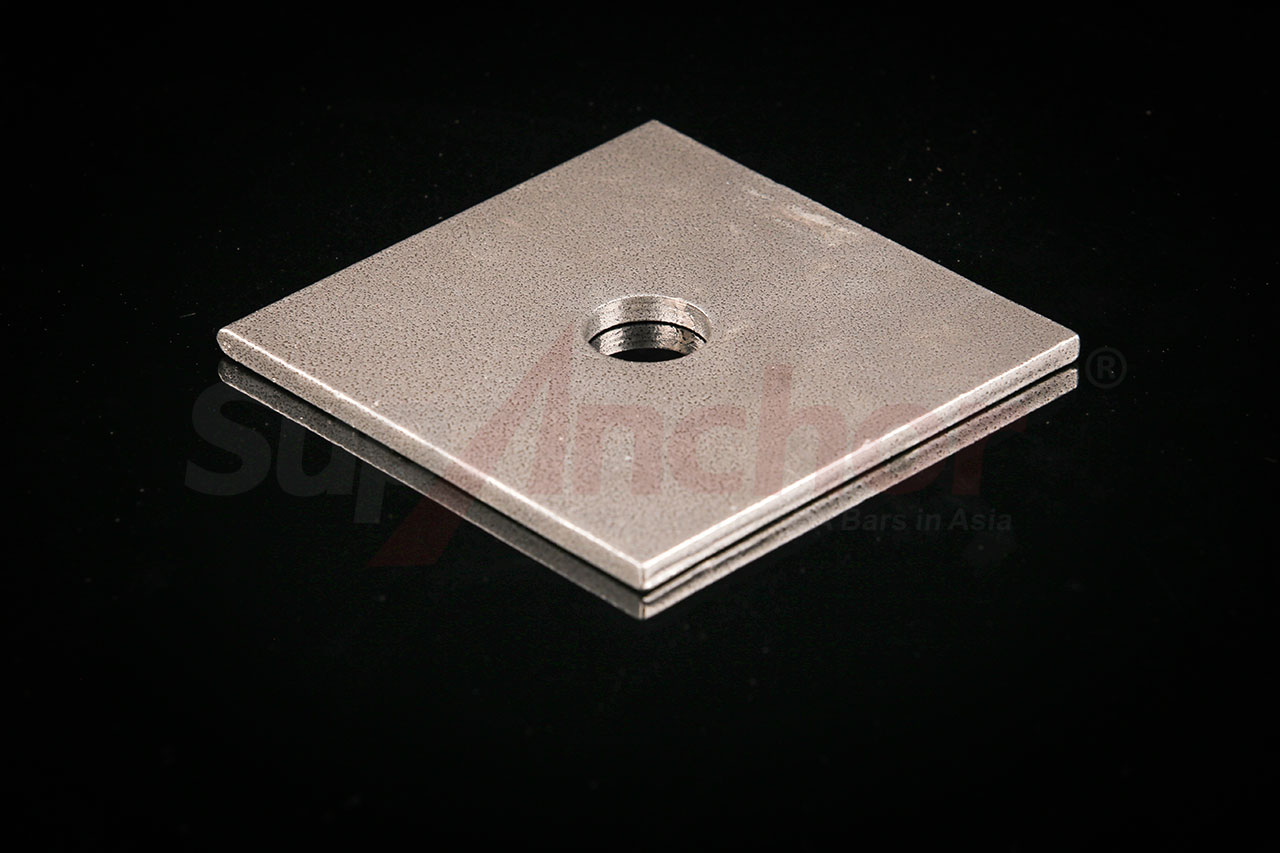

The Gotthard Base Tunnel extension, spanning over 15 kilometers, encountered varied rock types including fractured granite and schist, which posed significant risks of deformation and water ingress. On-site, construction teams employed SupAnchor's self drilling anchor bolts to secure tunnel walls and roofs, as depicted in the accompanying image. This method allowed for simultaneous drilling and grouting, reducing installation time and minimizing disruption in the confined underground environment. The project's scale, involving multiple access shafts and cross-passages, underscored the need for a efficient ground stabilization anchor system that could adapt to changing conditions while maintaining high safety standards.

SupAnchor's self drilling anchor bolt specifications were tailored to address the site's specific challenges, such as high tensile loads and corrosive groundwater. Key parameters include a tensile strength of 550 MPa, diameters ranging from 25 mm to 32 mm, lengths up to 12 meters, and hot-dip galvanized corrosion protection. These features ensure durability and resistance to environmental factors, crucial for long-term performance in tunneling applications. The hollow bar anchor design facilitates the drill-and-grout process, enabling rapid installation and immediate load-bearing capacity, which proved essential in stabilizing loose rock zones and preventing progressive failure.

| Parameter | Value |

|---|---|

| Tensile Strength | 550 MPa |

| Diameter | 25-32 mm |

| Length | Up to 12 m |

| Corrosion Protection | Hot-dip Galvanized |

| Application Type | Tunnel and Slope Support |

The high tensile strength of these self drilling bolts allows them to withstand significant ground movements, while the corrosion protection extends service life in humid underground conditions. By integrating these specs, the project achieved a 20% reduction in installation time compared to conventional methods, highlighting the efficiency of SupAnchor's geotechnical reinforcement system. This approach not only addressed immediate stability issues but also contributed to overall cost savings and enhanced safety protocols on site.

The successful application of SupAnchor's self drilling anchor for retaining walls and other structures reflects broader industry shifts toward sustainable and resilient infrastructure. With urbanization accelerating worldwide, projects like this underscore the growing demand for reliable ground anchor bolt systems in civil engineering. The global geotechnical engineering sector is increasingly prioritizing technologies that minimize environmental impact and maximize safety, such as micropile hollow bar anchors and rock bolts for underground mining. SupAnchor's innovations align with these trends, offering solutions that support everything from transportation networks to urban development, thereby reinforcing the importance of advanced soil nail system manufacturers in modern construction.

Moreover, the emphasis on geotechnical safety in projects like the Alpine tunnel highlights how self drilling bolt for civil engineering applications can mitigate risks in seismically active or geologically complex regions. As infrastructure ages and climate change introduces new challenges, the role of anchor bolt system for geotechnical engineering becomes ever more critical. SupAnchor's contributions in this arena not only enhance project outcomes but also set benchmarks for industry best practices, driving adoption of SDA bolt factory direct supply models that ensure quality and affordability.

SupAnchor has established itself as a leader in the geotechnical sector through its commitment to innovation, quality, and collaboration. Holding ISO 9001 certifications, the company emphasizes rigorous testing and continuous improvement in its product lines, including the self drilling anchor system and hollow bar anchors. Their global portfolio includes projects in Europe, North America, and Asia, where they have provided customized solutions for challenging environments, from mining operations to highway embankments. The core values of being professional, innovative, and collaborative are evident in their approach to customer partnerships, ensuring that each project benefits from tailored technical support and reliable performance.

By investing in research and development, SupAnchor has pioneered advancements in drill-and-grout bolt technology, making their products a go-to choice for engineers seeking efficient ground stabilization anchor systems. Their focus on direct supply from the ground anchor bolt factory ensures consistent quality and rapid delivery, which was crucial in the Alpine project's tight timelines. As the industry evolves, SupAnchor's role in promoting safer and more sustainable construction practices positions them at the forefront of geotechnical engineering, with a clear vision for future innovations in self drilling anchor bolts and related systems.

In conclusion, the integration of SupAnchor's self drilling anchor system in the Alpine tunnel project exemplifies how cutting-edge geotechnical solutions can overcome complex challenges while aligning with global infrastructure trends. As demand for reliable and efficient systems grows, SupAnchor's expertise in self drilling anchor bolts and geotechnical reinforcement will continue to play a vital role in shaping safer and more resilient built environments worldwide.

SupAnchor's self drilling anchor system addresses complex geology in a large-scale project, highlighting innovation in geotechnical engineering for global infrastructure trends.

SupAnchor's Sup2000 and Sup5000 grout pumps, with high delivery rates and robust design, optimize injection work in tunneling, civil engineering, and mining applications worldwide.

A large-scale tunnel project in Europe utilizes SupAnchor's self-drilling anchor bolts to overcome complex geology, improving infrastructure safety and efficiency.

SupAnchor introduces the GFRP SDA Bolt, an innovative self drilling anchor system that integrates drilling, grouting, and anchoring for fast installation in soft rock and clay soil, improving safety and efficiency in global infrastructure projects.

SupAnchor's advanced self drilling anchor bolt system provides critical support in a challenging Alpine tunneling project, showcasing innovation in geotechnical reinforcement systems for global infrastructure.