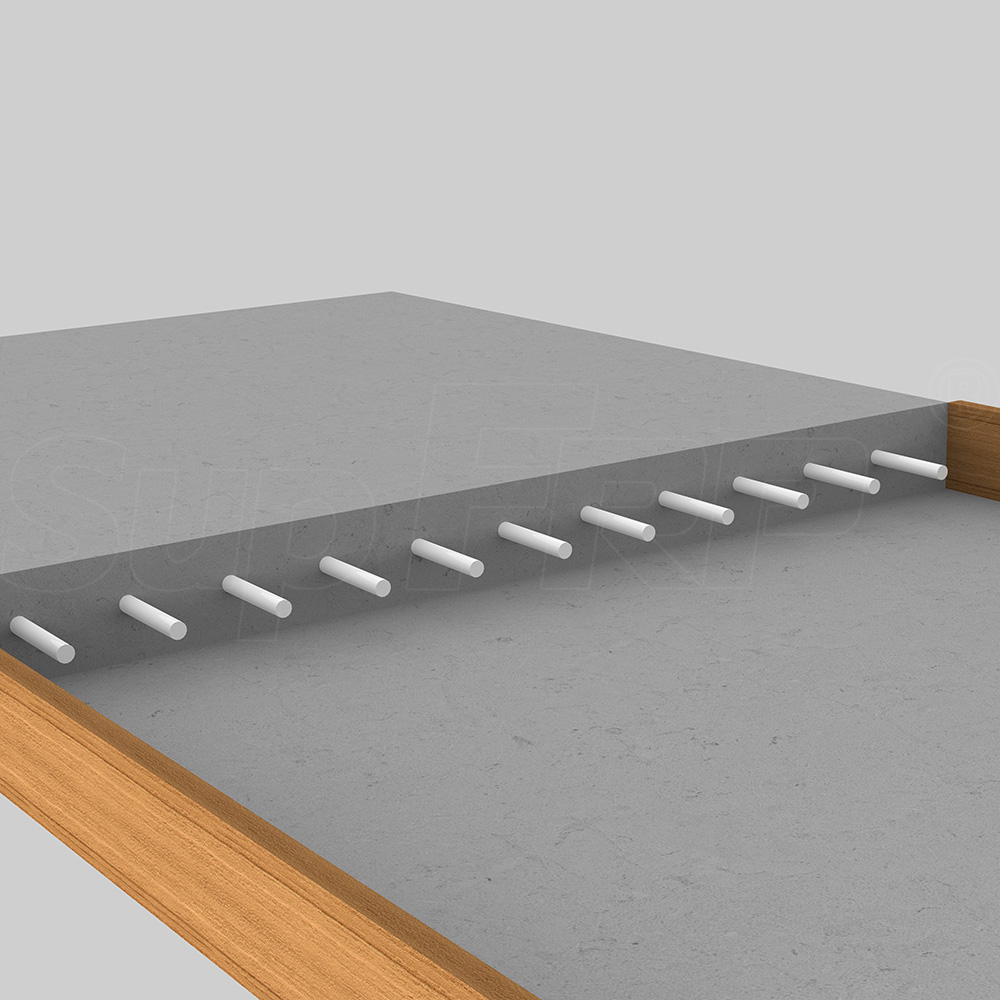

In a major highway expansion project across Northern Europe, engineers confronted persistent issues with thermal expansion and joint failures in concrete pavements due to harsh weather conditions. SupAnchor's GFRP Dowel Bar emerged as a key solution, providing reliable load transfer and enhancing structural integrity in challenging environments. This innovation addresses the need for durable, long-lasting materials in modern infrastructure, aligning with global sustainability goals.

The SupAnchor GFRP Dowel Bar, part of the company's advanced geotechnical reinforcement system, is engineered from high-quality glass fiber reinforced polymer. It facilitates horizontal movement in concrete slabs to accommodate thermal changes, ensuring stability without corrosion. Key parameters include transverse shear load, diameter, and service life, which directly tackle engineering challenges like joint slippage and material degradation. For instance, in applications such as jointed rigid pavements, the bar's non-conductive nature makes it ideal for areas with electromagnetic sensitivities. Below is a summary of technical data for various models:

| Model | Outside Diameter (mm) | Transverse Shear Load (kN) | Nominal Cross Sectional Area (sq. m) | Coefficient of Thermal Expansion (x10-6/℃) | Weight (kg/m) |

|---|---|---|---|---|---|

| DB16 | 16 | 35 | 200 | 9-11 | 0.43 |

| DB20 | 20 | 55 | 310 | 9-11 | 0.67 |

| DB25 | 25 | 85 | 490 | 9-11 | 1.05 |

| DB32 | 32 | 130 | 800 | 9-11 | 1.71 |

| DB38 | 38 | 180 | 1130 | 9-11 | 2.41 |

| DB45 | 45 | 255 | 1590 | 9-11 | 3.37 |

These specifications enable precise customization for projects, with the bar's high strength and superior load transfer efficiency reducing maintenance costs. For example, the DB32 model's 130 kN shear load capacity ensures robust performance in heavy-traffic areas, while the consistent thermal expansion coefficient minimizes stress cracks. This aligns with SupAnchor's broader self drilling anchor system offerings, which include hollow bar anchors for varied geotechnical needs.

The GFRP Dowel Bar is widely used in jointed rigid pavements, embankments, MSE walls, and construction joints, particularly in regions prone to temperature fluctuations. Its non-magnetic and non-conductive properties make it essential for work areas near sensitive equipment, such as in tunneling and mining operations. By replacing traditional steel dowels, it eliminates rust-related failures, extending infrastructure lifespan. In Europe and North America, this has led to increased adoption in urban development and transportation projects, where the self drilling anchor bolt technology from SupAnchor complements this product for comprehensive ground stabilization.

This innovation contributes significantly to global infrastructure by improving geotechnical safety and reducing environmental impact. In sectors like tunneling and mining, the use of drill-and-grout bolt systems alongside GFRP dowels enhances stability in unstable soils. The long service life and rust-free nature lower lifecycle costs, supporting economic growth in developing regions. SupAnchor's role in this aligns with industry trends toward resilient materials, potentially reducing project delays and enhancing public safety in critical applications.

SupAnchor, known for its professional and collaborative approach, has invested heavily in R&D to develop products like the GFRP Dowel Bar. With ISO certifications and a track record in global projects, the company emphasizes innovation in geotechnical reinforcement systems. Their self drilling anchor system portfolio, including hollow bar anchors, demonstrates a commitment to solving complex engineering challenges. By fostering partnerships and adhering to high standards, SupAnchor continues to influence the market, ensuring that solutions like the drill-and-grout bolt meet evolving demands for durability and efficiency.

In summary, the SupAnchor GFRP Dowel Bar represents a leap forward in construction technology, offering tailored solutions for modern infrastructure. Its integration into projects worldwide underscores the brand's dedication to innovation and quality, paving the way for safer, more sustainable developments.

SupAnchor's self drilling anchor system addresses complex geology in a large-scale project, highlighting innovation in geotechnical engineering for global infrastructure trends.

SupAnchor's Sup2000 and Sup5000 grout pumps, with high delivery rates and robust design, optimize injection work in tunneling, civil engineering, and mining applications worldwide.

A large-scale tunnel project in Europe utilizes SupAnchor's self-drilling anchor bolts to overcome complex geology, improving infrastructure safety and efficiency.

SupAnchor introduces the GFRP SDA Bolt, an innovative self drilling anchor system that integrates drilling, grouting, and anchoring for fast installation in soft rock and clay soil, improving safety and efficiency in global infrastructure projects.

SupAnchor's advanced self drilling anchor bolt system provides critical support in a challenging Alpine tunneling project, showcasing innovation in geotechnical reinforcement systems for global infrastructure.