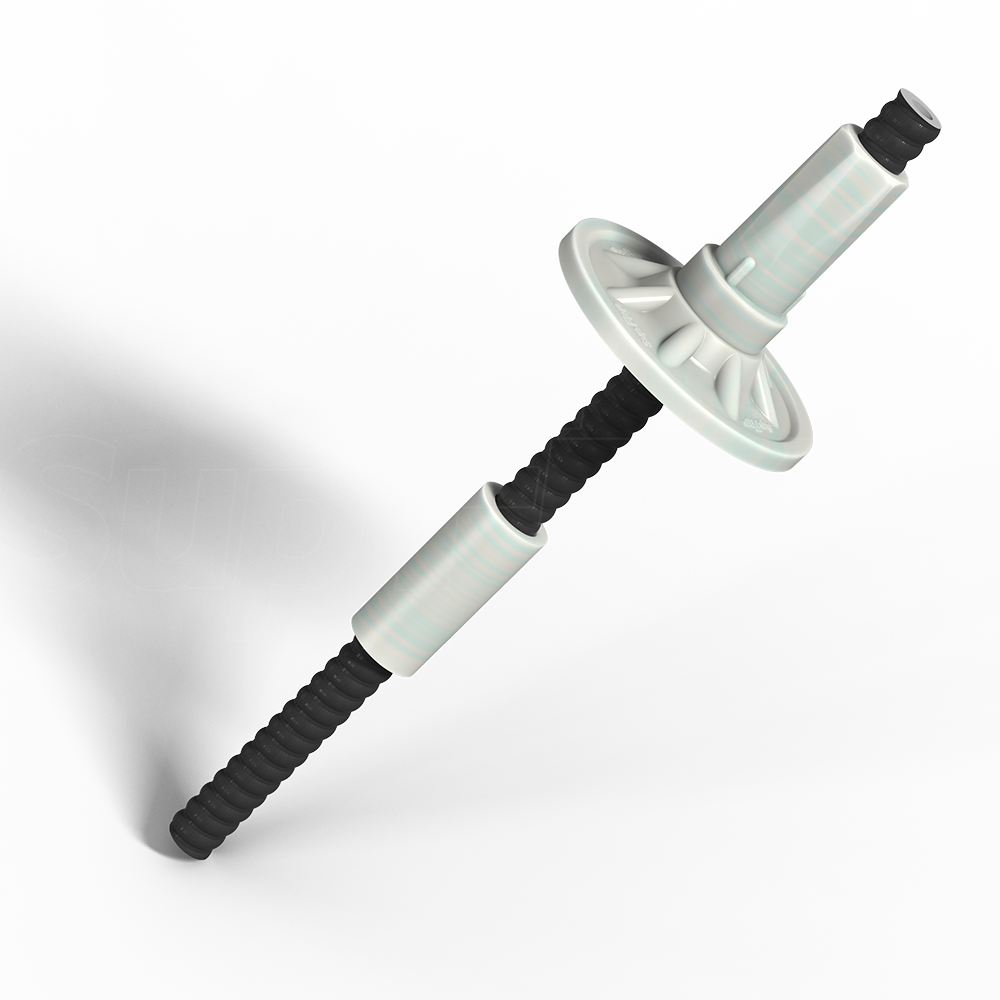

As global infrastructure projects expand into challenging terrains, engineers face increasing pressures from unstable slopes, soft rock conditions, and confined spaces in tunneling and mining. SupAnchor's GFRP Hollow Injection Bolt, part of the innovative SupFRP series, is addressing these demands by providing a reliable self drilling anchor system that combines high load-bearing capacity with efficient grouting integration. This product is pivotal in ensuring long-term stability and safety in diverse geotechnical environments.

On-site installation begins with drilling into rock or soil, where the hollow bar anchor allows for simultaneous grout injection under high pressure, ensuring full bonding and immediate load-bearing post-installation. This drill-and-grout bolt system is designed to handle tensile stresses up to 490 kN and pressure resistance up to 30 MPa, depending on the model. Key parameters, such as lightweight design and high corrosion resistance, directly address common challenges like handling ease in remote areas and durability in harsh conditions. For instance, the low weight reduces labor costs and equipment strain, while the cuttability feature allows for precise adjustments during installation.

| Model | Tensile Load (kN) | Pressure Resistance (MPa) | Weight (kg/m) |

|---|---|---|---|

| H25/220 | 220 | 5 | 0.64 |

| H28/320 | 320 | 5 | 0.88 |

| H32/360 | 360 | 5 | 1.20 |

These specifications enable the geotechnical reinforcement system to perform reliably in applications such as slope stabilization, where high tensile loads prevent landslides, and in TBM face support, where pressure resistance ensures tunnel integrity during excavation. The consistent tensile E-modulus of 45 GPa across models guarantees uniform deformation behavior, crucial for maintaining structural harmony in complex geological settings.

The self drilling anchor bolt is versatile, with primary uses in slope stabilization, TBM face support, forepoling, confined ground conditions, soft rock stabilization, and permanent installations. Its hollow design facilitates efficient grout flow, enhancing bond strength with surrounding materials and reducing the risk of voids that could compromise safety. Key advantages include:

In practice, this geotechnical reinforcement system has been deployed in European tunneling projects, where it supports face stability in TBMs, and in North American mining operations, providing forepoling to prevent collapses. The ability to remain in place post-injection reduces maintenance and enhances project longevity, making it a cost-effective solution for infrastructure developers.

The adoption of SupAnchor's self drilling anchor system is driving advancements in global infrastructure, particularly in tunneling, mining, and urban development. By improving geotechnical safety, this hollow bar anchor minimizes risks of failures that could lead to costly delays or accidents. In regions prone to landslides or seismic activity, its high tensile strength and corrosion resistance offer a sustainable alternative to traditional steel bolts, reducing environmental impact and lifecycle costs. The drill-and-grout bolt technology aligns with international safety standards, supporting projects from the Alps to the Rockies, and underscores the growing demand for innovative geotechnical solutions in an era of rapid urbanization.

SupAnchor has built a reputation for professionalism and innovation through rigorous R&D and adherence to ISO certifications, ensuring that products like the GFRP Hollow Injection Bolt meet global quality benchmarks. Collaborations with engineering firms worldwide have led to successful implementations in large-scale projects, reinforcing the brand's message of being professional, innovative, and collaborative. By continuously refining their geotechnical reinforcement systems, SupAnchor contributes to safer, more efficient construction practices, setting a benchmark for the industry.

In summary, SupAnchor's GFRP Hollow Injection Bolt represents a significant leap in geotechnical engineering, offering a reliable self drilling anchor system that addresses modern infrastructure challenges. With its robust technical features and broad applicability, it stands as a testament to the company's commitment to excellence and safety in the built environment.

SupAnchor's self drilling anchor system addresses complex geology in a large-scale project, highlighting innovation in geotechnical engineering for global infrastructure trends.

SupAnchor's Sup2000 and Sup5000 grout pumps, with high delivery rates and robust design, optimize injection work in tunneling, civil engineering, and mining applications worldwide.

A large-scale tunnel project in Europe utilizes SupAnchor's self-drilling anchor bolts to overcome complex geology, improving infrastructure safety and efficiency.

SupAnchor introduces the GFRP SDA Bolt, an innovative self drilling anchor system that integrates drilling, grouting, and anchoring for fast installation in soft rock and clay soil, improving safety and efficiency in global infrastructure projects.

SupAnchor's advanced self drilling anchor bolt system provides critical support in a challenging Alpine tunneling project, showcasing innovation in geotechnical reinforcement systems for global infrastructure.