In the demanding environments of modern mining and tunneling projects, unstable geological conditions often threaten worker safety and project efficiency. SupAnchor addresses these challenges with its SupHulk friction rock bolt system, a self drilling anchor system designed to provide robust, immediate rock reinforcement. This innovation is crucial for projects in varied terrains, from deep mines to urban tunnels, where rapid installation and high performance are essential.

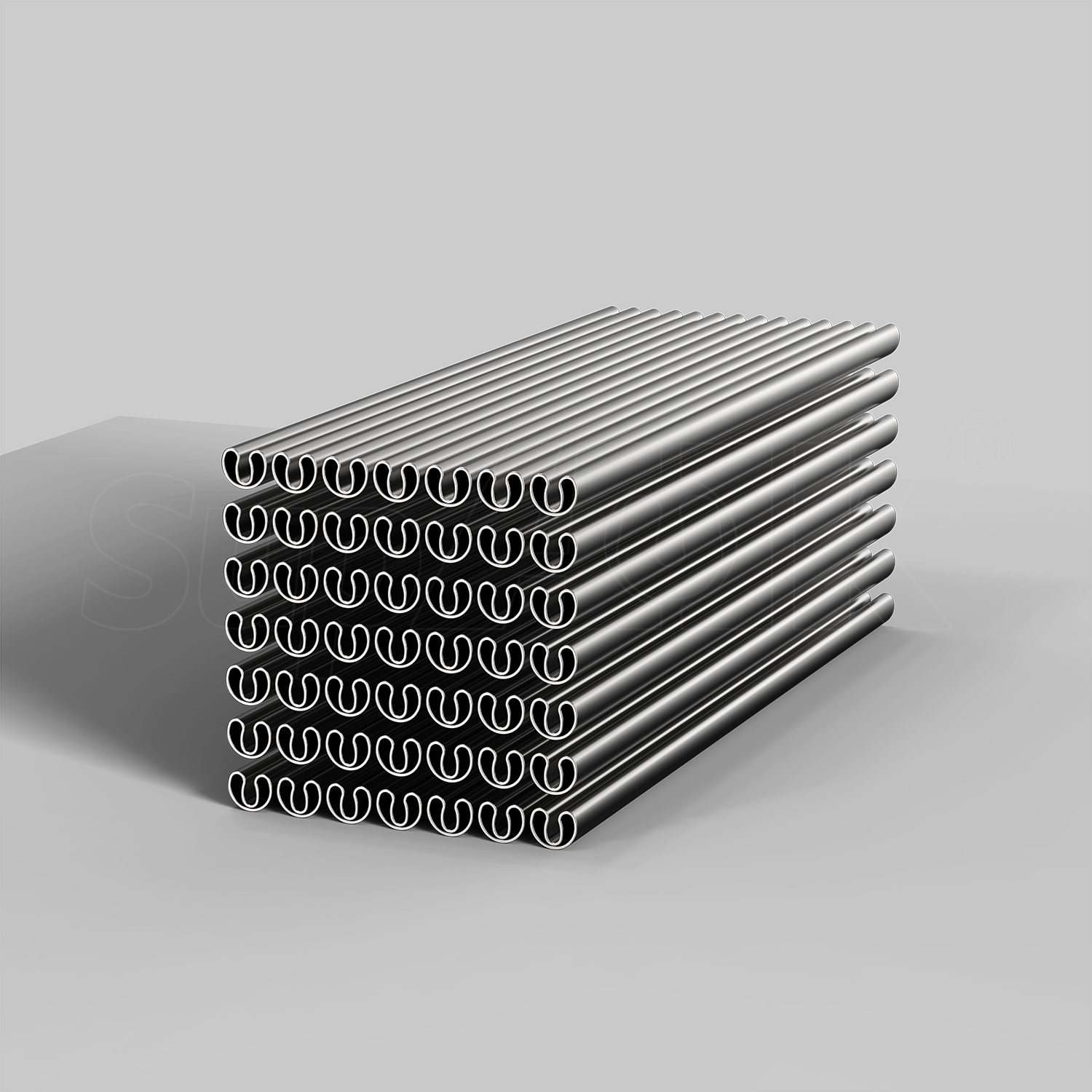

The SupHulk system streamlines on-site processes: operators drill a hole, insert the self drilling anchor bolt, and inflate it to a preset pressure using a specialized pump that ensures quality control. This geotechnical reinforcement system adapts to engineering needs by offering key parameters that solve common challenges like rock movement and load distribution. For instance, the Premium (PM) series features high yield loads and good deformability, allowing immediate load bearing and absorption of rock shifts. Below is a summary of critical specs for the PM models, highlighting their role in enhancing safety and efficiency.

| Model | Min Breaking Load (kN) | Min Yield Load (kN) | Inflation Pressure (bar) | Hole Diameter (mm) |

|---|---|---|---|---|

| PM12 | 110 | 100 | 300 | 32-39 |

| PM16 | 160 | 130 | 240 | 43-52 |

| PM24 | 240 | 200 | 300 | 43-52 |

These specifications, such as the minimum breaking loads of 110 kN to 240 kN, ensure the self drilling anchor bolt can handle high-stress conditions without failure. The system's ability to form friction along the entire bolt length distributes forces evenly, reducing the risk of localized failures. Additionally, features like a 10% minimum elongation allow for flexibility in dynamic rock environments, making it a reliable choice for geotechnical reinforcement systems worldwide.

SupHulk rock bolts are highly versatile, finding use in diverse mining and tunneling applications. In tunneling, they serve as pattern bolts for systematic anchoring, supporting excavations in projects ranging from subway expansions to highway tunnels. For mining, common uses include roof bolting and hanging wall bolting, where the self drilling anchor system provides rapid, safe reinforcement in low to medium stress scenarios. Key features that enhance adaptability include:

This hollow bar anchor technology is particularly valuable in civil engineering, where projects like dam constructions or slope stabilizations require dependable ground anchor solutions. By integrating this self drilling anchor system, engineers can achieve faster project timelines and improved safety outcomes.

The global infrastructure sector benefits significantly from innovations like the SupHulk system, as urbanization and resource extraction drive demand for safer, more efficient geotechnical reinforcement systems. In regions prone to geological hazards, such as earthquake zones or unstable mining areas, this self drilling anchor bolt technology mitigates risks by offering immediate load capacity and durability. SupAnchor's commitment to R&D and innovation is evident in their ISO-certified processes and collaborative projects across Europe and the Americas, reinforcing their reputation as a professional and innovative leader. The brand's focus on collaborative solutions ensures that their products meet international standards, supporting sustainable development in tunneling and mining industries. As infrastructure projects grow in scale and complexity, the SupHulk system's engineering adaptability and market value position it as a key player in enhancing global geotechnical safety.

SupAnchor's self drilling anchor system addresses complex geology in a large-scale project, highlighting innovation in geotechnical engineering for global infrastructure trends.

SupAnchor's Sup2000 and Sup5000 grout pumps, with high delivery rates and robust design, optimize injection work in tunneling, civil engineering, and mining applications worldwide.

A large-scale tunnel project in Europe utilizes SupAnchor's self-drilling anchor bolts to overcome complex geology, improving infrastructure safety and efficiency.

SupAnchor introduces the GFRP SDA Bolt, an innovative self drilling anchor system that integrates drilling, grouting, and anchoring for fast installation in soft rock and clay soil, improving safety and efficiency in global infrastructure projects.

SupAnchor's advanced self drilling anchor bolt system provides critical support in a challenging Alpine tunneling project, showcasing innovation in geotechnical reinforcement systems for global infrastructure.