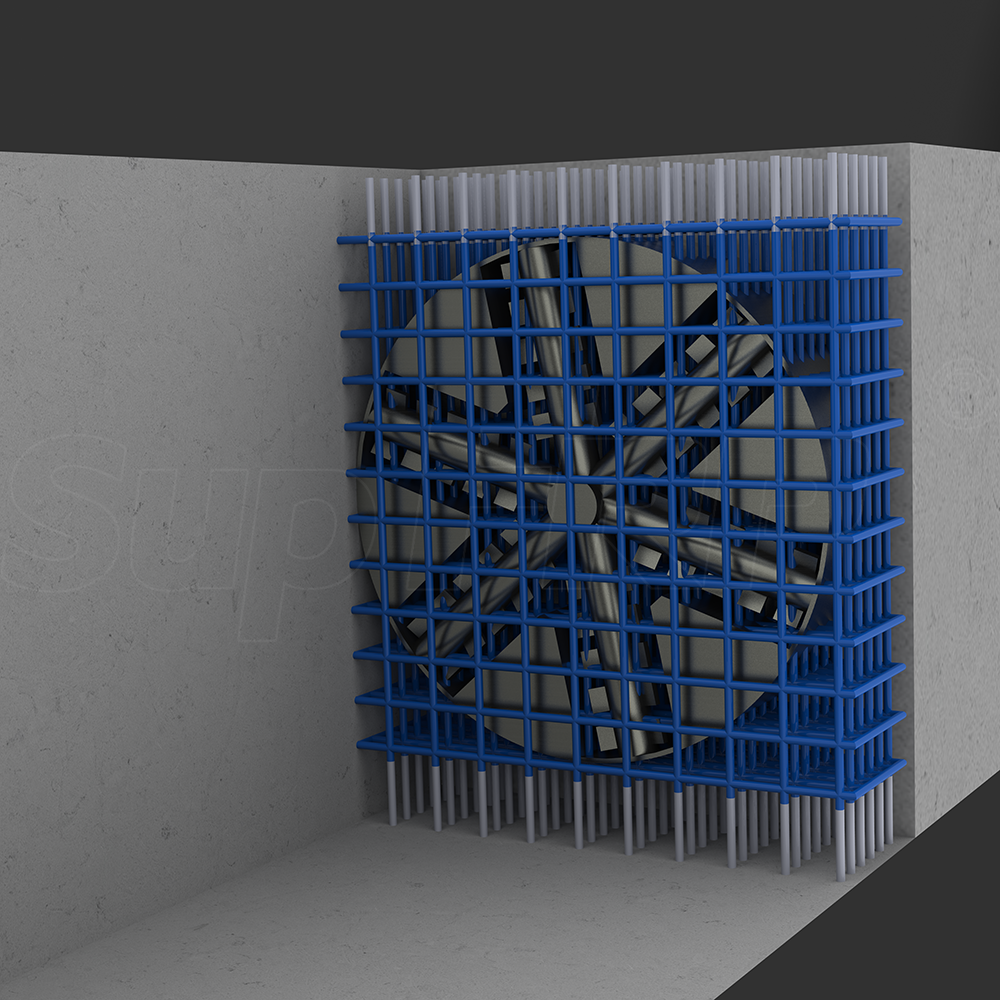

In coastal and industrial regions where corrosion poses significant threats to traditional steel reinforcements, SupAnchor has introduced its SupFRP® GFRP Reinforcement Rebar, a high-performance alternative designed to address these challenges. This product is pivotal in projects involving soft-eye excavation, bridge decks, and sea walls, where durability and reliability are critical. SupAnchor's role in providing advanced geotechnical reinforcement systems ensures that infrastructure can withstand harsh conditions, reducing long-term maintenance costs and enhancing safety.

The SupFRP GFRP rebar is manufactured from corrosion-resistant resin and fiberglass, offering exceptional bonding with concrete and high tensile strength. Key parameters include outside diameter, guaranteed tensile load, tensile strength, and weight, which are tailored to meet diverse engineering needs. For example, in tunneling or mining applications, the rebar's non-conductive and non-magnetic properties prevent interference with electronic systems, while its easy handling and cost-effectiveness streamline construction processes. Below is a summary of selected technical data:

| Product | Outside Diameter (mm) | Guaranteed Tensile Load (kN) | Tensile Strength (MPa) | Weight (kg/m) |

|---|---|---|---|---|

| ReB-8 | 9 | 50.3 | 1000 | 0.125 |

| ReB-16 | 18 | 201 | 1000 | 0.50 |

| ReB-25 | 28 | 491 | 1000 | 1.20 |

| ReB-32 | 36 | 720 | 900 | 2.00 |

These specifications enable the rebar to solve common engineering challenges, such as corrosion in marine environments or high-stress conditions in infrastructural buildings. By providing a consistent tensile E-modulus of 50 GPa and ultimate strain of 2%, it ensures structural integrity and adaptability across various scales, from small precast elements to large bridge decks.

The GFRP rebar is ideally suited for a wide range of applications, leveraging its high corrosion resistance and ease of use. Key scenarios include:

This versatility makes it a core component of SupAnchor's geotechnical reinforcement system, enhancing safety and efficiency in projects across Europe and America. For instance, in urban development, the rebar's easy cutting and handling reduce labor costs, while its non-conductive properties are crucial in areas with electrical hazards.

The introduction of GFRP rebar aligns with global efforts to improve infrastructure resilience and sustainability. By replacing traditional materials, it reduces environmental impact and lifecycle costs, particularly in sectors like mining and tunneling where geotechnical safety is paramount. SupAnchor's product contributes to safer self drilling anchor systems by providing reliable internal reinforcement, minimizing the risk of failures in critical structures. This innovation supports economic growth by extending the service life of assets such as highways and industrial facilities, ultimately fostering more collaborative and professional approaches to construction worldwide.

SupAnchor's commitment to innovation is demonstrated through extensive R&D and adherence to international standards like ISO certifications. The company's portfolio, including self drilling anchor bolts and hollow bar anchors, reflects a focus on professional and collaborative solutions. With successful projects in diverse regions, SupAnchor emphasizes quality and adaptability, ensuring that products like the GFRP rebar meet the evolving demands of the drill-and-grout bolt market. This brand influence reinforces SupAnchor's position as a leader in geotechnical reinforcement systems, driving advancements that benefit global infrastructure.

SupAnchor's self drilling anchor system addresses complex geology in a large-scale project, highlighting innovation in geotechnical engineering for global infrastructure trends.

SupAnchor's Sup2000 and Sup5000 grout pumps, with high delivery rates and robust design, optimize injection work in tunneling, civil engineering, and mining applications worldwide.

A large-scale tunnel project in Europe utilizes SupAnchor's self-drilling anchor bolts to overcome complex geology, improving infrastructure safety and efficiency.

SupAnchor introduces the GFRP SDA Bolt, an innovative self drilling anchor system that integrates drilling, grouting, and anchoring for fast installation in soft rock and clay soil, improving safety and efficiency in global infrastructure projects.

SupAnchor's advanced self drilling anchor bolt system provides critical support in a challenging Alpine tunneling project, showcasing innovation in geotechnical reinforcement systems for global infrastructure.