As geotechnical engineering challenges intensify across Europe and America, with projects ranging from urban tunneling to remote mining operations, the demand for reliable reinforcement solutions has never been higher. SupAnchor, a leader in geotechnical systems, has responded with the launch of its SupFRP® GFRP Hollow Injection Bolt. This innovative product, part of the SupFRP® series, is designed to address critical issues in slope stabilization, tunnel face support, and other demanding applications, combining the functions of a rock bolt and injection for superior performance and durability.

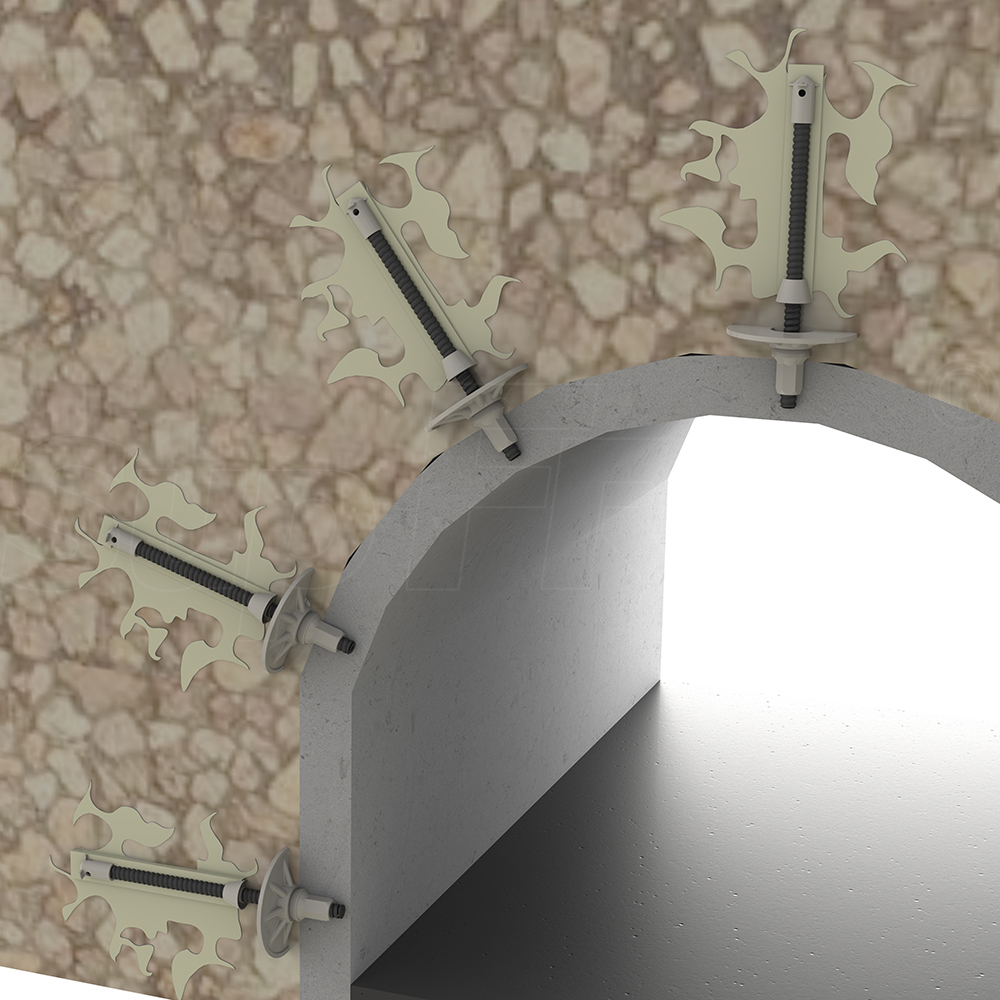

The SupAnchor GFRP hollow injection bolt is engineered for high tensile load and pressure resistance, making it a versatile tool in geotechnical projects. Its hollow design allows for efficient injection of grouting materials, ensuring excellent bonding force and full grouting under high pressure. This self drilling anchor system is lightweight for easy handling, yet robust enough to withstand significant stresses, solving common engineering challenges such as corrosion, weight limitations, and installation speed.

Key technical specifications highlight its adaptability. For instance, the bolt offers guaranteed tensile loads ranging from 220 kN to 490 kN across different models, with pressure resistance up to 30 MPa. Its cuttability allows for on-site customization, while high corrosion resistance ensures longevity in permanent applications. Below is a summary table of key parameters from the product line:

| Model | Guaranteed Tensile Load (kN) | Pressure Resistance (MPa) | Weight (kg/m) | Key Applications |

|---|---|---|---|---|

| H25/220 | 220 | 5 | 0.64 | Slope stabilization, confined ground |

| H28/320 | 320 | 5 | 0.88 | TBM face support, soft rock |

| H32/360 | 360 | 5 | 1.20 | Forepoling, permanent applications |

| H38/490 | 490 | 5 | 1.5 | High-load scenarios |

| H22/230 | 230 | 18 | 0.58 | Lightweight applications |

| H25/300 | 300 | 30 | 0.79 | Versatile use in geotechnical reinforcement |

This hollow bar anchor system integrates drill-and-grout technology, allowing the bolt to remain in place post-injection and work with plates and nuts for effective load distribution. Its high tensile E-modulus of 45 GPa and ultimate strain of 2.0% ensure reliability under dynamic conditions, making it a cornerstone of modern geotechnical reinforcement systems.

The SupAnchor self drilling anchor bolt is designed for a wide array of geotechnical challenges, enhancing safety and efficiency in various projects. Its applications include slope stabilization in landslide-prone areas, where it provides robust support to prevent soil erosion. In tunnel boring machine (TBM) face support, it offers temporary reinforcement during excavation, reducing risks and improving workflow. For forepoling, it stabilizes ground ahead of excavation, while in confined ground conditions, its lightweight nature facilitates easy installation. Additionally, it excels in stabilizing soft rock and serves in permanent applications due to its corrosion resistance, making it ideal for long-term infrastructure like bridges and retaining walls.

This geotechnical reinforcement system addresses specific engineering needs by enabling quick deployment and reducing labor costs. For example, in mining operations, the bolt's high pressure resistance allows for secure anchoring in volatile environments, while in urban construction, its cuttability supports tailored solutions for complex layouts. By integrating injection and load-bearing functions, it streamlines processes that traditionally required multiple steps, showcasing SupAnchor's innovation in self drilling anchor systems.

The introduction of the GFRP hollow injection bolt holds significant value for global infrastructure development. As economies expand and projects push into challenging terrains, reliable reinforcement tools become critical for safety and sustainability. In industries such as tunneling, mining, and civil engineering, this bolt enhances project viability by reducing downtime and preventing accidents. Its corrosion-resistant properties contribute to lower maintenance costs and extended service life, aligning with environmental goals by minimizing resource use.

SupAnchor's product supports international safety standards and regulatory frameworks, offering solutions that meet the rigorous demands of European and American markets. By improving geotechnical stability, it aids in disaster prevention, such as in earthquake-prone regions or areas with unstable slopes, thereby protecting communities and assets. The bolt's versatility in applications from slope stabilization to TBM face support underscores its role as a key component in advancing global construction methodologies.

SupAnchor has established itself as a professional and innovative force in the geotechnical industry, driven by extensive research and development. The SupFRP® series, including this hollow injection bolt, reflects the company's commitment to cutting-edge technology and quality assurance, backed by ISO certifications. Through collaborative projects worldwide, SupAnchor works closely with engineers, contractors, and stakeholders to develop tailored solutions that address real-world challenges.

The brand message of professionalism, innovation, and collaboration is evident in every aspect of the product, from its design to post-sales support. By fostering partnerships and investing in R&D, SupAnchor aims to set benchmarks in geotechnical engineering, ensuring that clients benefit from not just a product, but a comprehensive system that enhances project outcomes. This approach has led to successful implementations in diverse settings, reinforcing SupAnchor's reputation as a trusted provider of self drilling anchor bolts and related systems.

In summary, the SupAnchor GFRP hollow injection bolt represents a significant advancement in geotechnical reinforcement, offering a blend of high performance, ease of use, and durability. By addressing key engineering challenges and supporting global infrastructure needs, it exemplifies SupAnchor's role in shaping safer and more efficient construction practices. As the demand for reliable geotechnical solutions grows, this product is poised to become a standard in projects requiring robust self drilling anchor systems and innovative drill-and-grout technology.

SupAnchor's self drilling anchor system addresses complex geology in a large-scale project, highlighting innovation in geotechnical engineering for global infrastructure trends.

SupAnchor's Sup2000 and Sup5000 grout pumps, with high delivery rates and robust design, optimize injection work in tunneling, civil engineering, and mining applications worldwide.

A large-scale tunnel project in Europe utilizes SupAnchor's self-drilling anchor bolts to overcome complex geology, improving infrastructure safety and efficiency.

SupAnchor introduces the GFRP SDA Bolt, an innovative self drilling anchor system that integrates drilling, grouting, and anchoring for fast installation in soft rock and clay soil, improving safety and efficiency in global infrastructure projects.

SupAnchor's advanced self drilling anchor bolt system provides critical support in a challenging Alpine tunneling project, showcasing innovation in geotechnical reinforcement systems for global infrastructure.