In the mountainous regions of Europe, a major highway expansion project faced significant geotechnical challenges, including loose soil and unstable slopes that threatened construction safety and timeline. SupAnchor, a leading manufacturer of geotechnical reinforcement systems, was engaged to provide its innovative self drilling anchor system for ground stabilization. This project, involving extensive tunneling and slope reinforcement, underscores the growing reliance on advanced solutions in civil engineering to address complex geological conditions.

The construction site, as depicted in the image, showcases SupAnchor's self drilling anchor bolts in action, drilling directly into the soil and rock without pre-drilling, which accelerates the installation process and reduces labor costs. The system's efficiency is critical in this high-risk environment, where timely completion is essential for minimizing disruptions. Key product parameters were tailored to meet the site's specific needs, ensuring optimal performance and durability.

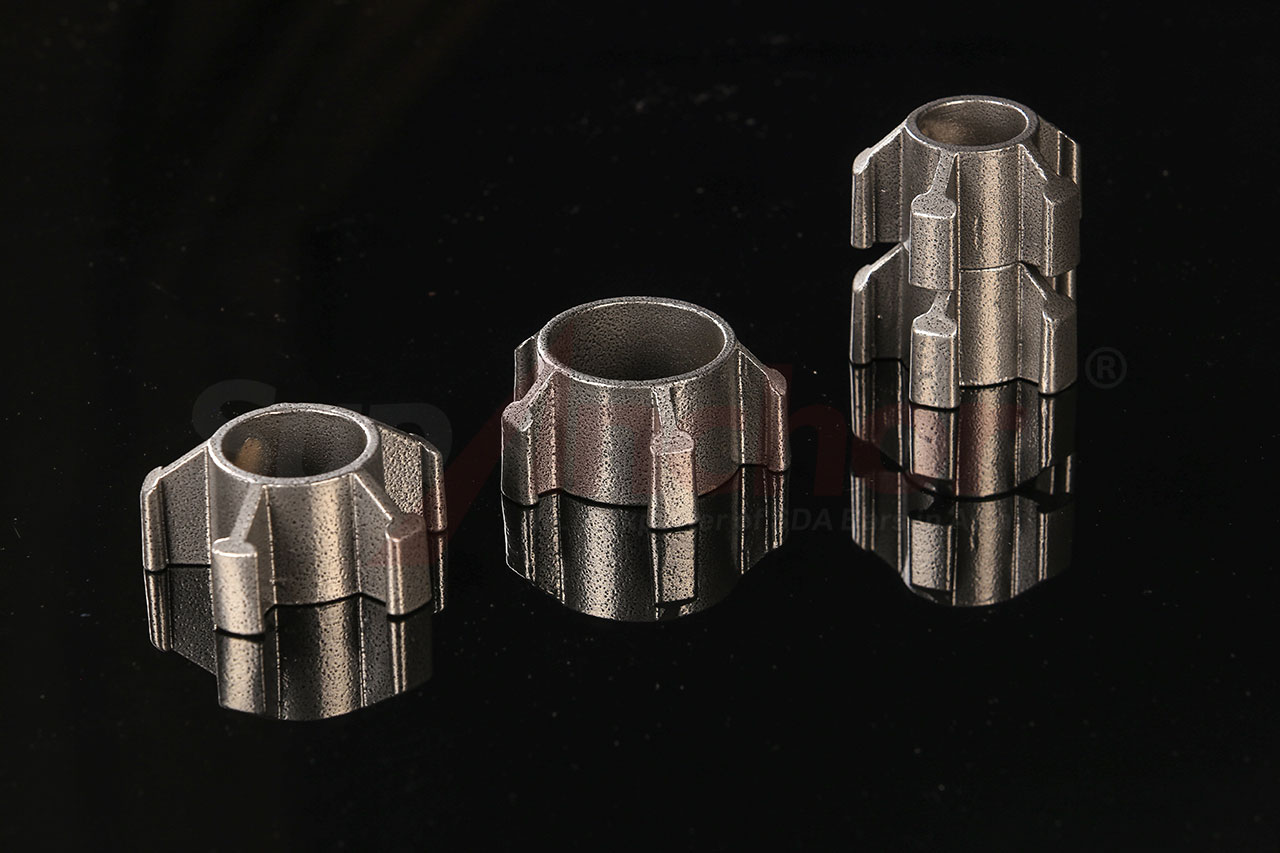

SupAnchor's self drilling anchor bolts feature robust specifications that directly address the geological challenges. For instance, the hollow bar anchor design allows for simultaneous drilling and grouting, enhancing bond strength and stability. Below are the detailed technical parameters used in this project:

| Parameter | Specification |

|---|---|

| Tensile Strength | 600 MPa |

| Diameter | 52 mm |

| Length | Customizable up to 15 meters |

| Corrosion Protection | Hot-dip galvanized coating |

| Application Type | Drill-and-grout bolt for slope stabilization |

These specifications enable the ground anchor bolt system to withstand high tensile loads and corrosive environments, making it ideal for long-term infrastructure projects. The self drilling anchor bolt's design reduces installation time by up to 30% compared to traditional methods, as reported by site engineers. This efficiency is vital in projects where geological instability poses ongoing risks, such as landslides or soil erosion.

This project reflects broader global trends in infrastructure development, where geotechnical safety is paramount. With urbanization and climate change increasing the frequency of geological hazards, the demand for reliable ground stabilization anchor systems is rising. SupAnchor's self drilling anchor system aligns with these trends by offering solutions for tunneling, mining, and transportation projects worldwide. For example, similar systems are being adopted in North American and Asian markets for retaining walls and underground mining applications, highlighting the versatility of the soil nail system manufacturer's offerings.

Moreover, the use of micropile hollow bar anchors and other geotechnical reinforcement systems is becoming standard in civil engineering, driven by stricter safety regulations and the need for sustainable construction. SupAnchor's contributions in this area demonstrate how innovation can enhance project resilience, reduce environmental impact, and lower lifecycle costs. As infrastructure investments grow, particularly in developing regions, the role of advanced anchor bolt systems for geotechnical engineering will only expand.

SupAnchor emphasizes its core values of professionalism, innovation, and collaboration through this project. As a ground anchor bolt factory with ISO 9001 certification, the company adheres to rigorous quality standards, ensuring that products like the self drilling anchor for retaining walls meet international benchmarks. Their global portfolio includes projects in over 20 countries, showcasing their expertise in diverse geotechnical conditions.

Innovation is at the heart of SupAnchor's approach; for instance, their SDA bolt factory direct supply model streamlines logistics, reducing lead times and costs for clients. By collaborating with engineering firms and contractors, SupAnchor tailors solutions to specific site challenges, such as using rock bolt for underground mining in hazardous terrains. This collaborative spirit fosters trust and long-term partnerships, reinforcing the brand's reputation as a leader in the geotechnical sector.

Looking ahead, SupAnchor continues to invest in research and development to advance self drilling bolt for civil engineering applications, with a focus on digital integration and eco-friendly materials. Their efforts contribute to safer, more efficient infrastructure worldwide, aligning with global sustainability goals.

In conclusion, SupAnchor's self drilling anchor system not only solved immediate geotechnical challenges in this highway project but also set a precedent for future applications in the industry. By combining technical excellence with strategic innovation, the company solidifies its position as a key player in the global market for geotechnical reinforcement.

SupAnchor's self drilling anchor system addresses complex geology in a large-scale project, highlighting innovation in geotechnical engineering for global infrastructure trends.

SupAnchor's Sup2000 and Sup5000 grout pumps, with high delivery rates and robust design, optimize injection work in tunneling, civil engineering, and mining applications worldwide.

A large-scale tunnel project in Europe utilizes SupAnchor's self-drilling anchor bolts to overcome complex geology, improving infrastructure safety and efficiency.

SupAnchor introduces the GFRP SDA Bolt, an innovative self drilling anchor system that integrates drilling, grouting, and anchoring for fast installation in soft rock and clay soil, improving safety and efficiency in global infrastructure projects.

SupAnchor's advanced self drilling anchor bolt system provides critical support in a challenging Alpine tunneling project, showcasing innovation in geotechnical reinforcement systems for global infrastructure.