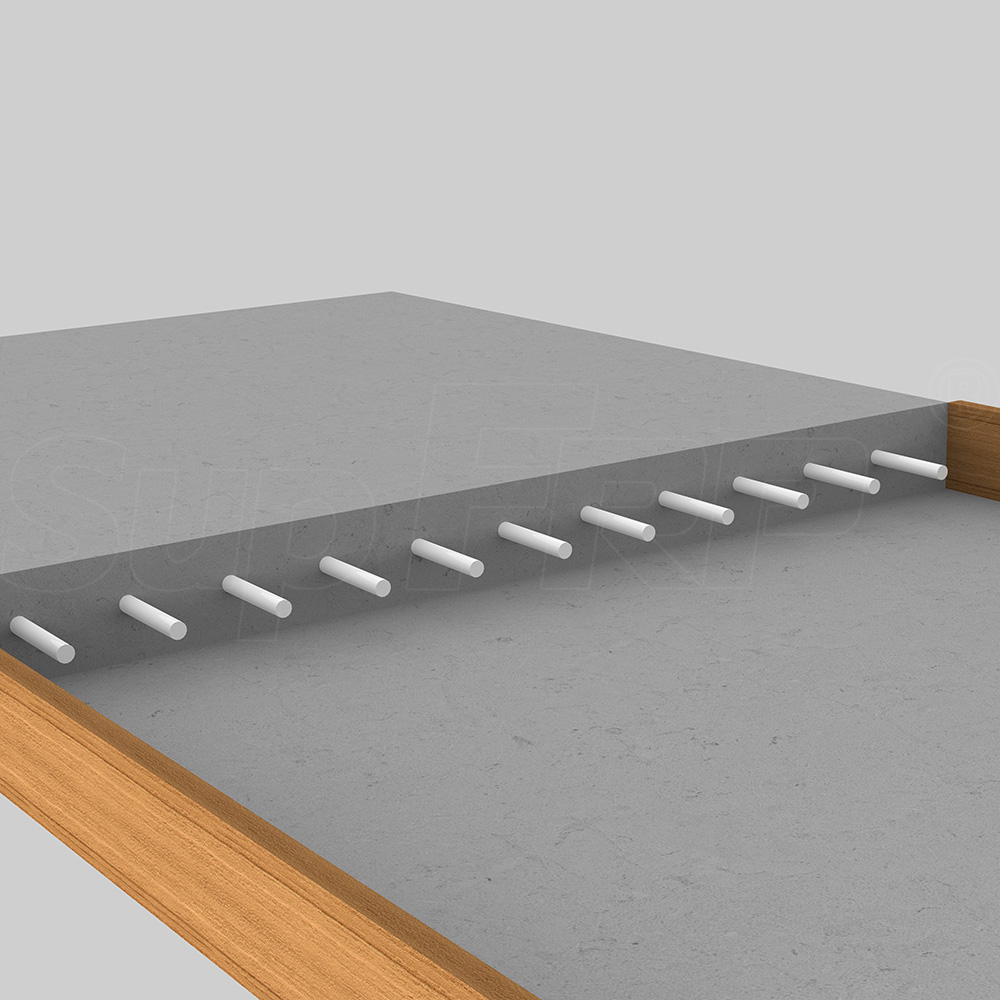

In recent years, European and American infrastructure projects have faced increasing challenges related to thermal expansion, corrosion, and the need for durable construction materials in diverse geological conditions. SupAnchor®, a leader in geotechnical reinforcement systems, has introduced its SupFRP® GFRP Dowel Bar to address these issues, providing a reliable solution for load transfer in concrete slabs. This product is designed to offer superior performance in jointed rigid pavements, embankments, and other critical applications, ensuring structural stability and longevity.

The SupFRP® GFRP Dowel Bar is manufactured from premium raw materials, allowing customization to meet specific project requirements. It functions as a mechanical link between adjacent concrete slabs, facilitating horizontal movements to accommodate thermal fluctuations while maintaining load transfer efficiency. Key advantages include a service life exceeding 100 years, rust-free properties, high strength, non-conductivity, and non-magnetic characteristics, making it ideal for environments with electromagnetic sensitivities. These features solve engineering challenges by reducing maintenance costs, enhancing safety, and improving overall structural integrity in infrastructure projects.

To illustrate the technical specifications, the following table provides detailed data for various models, showcasing the adaptability of SupAnchor's dowel bars in different engineering scenarios. This data underscores how the product's parameters, such as transverse shear load and diameter, align with the demands of modern construction, including those addressed by self drilling anchor systems in geotechnical reinforcement.

| Model | Outside Diameter (mm) | Transverse Shear Load (kN) | Nominal Cross Sectional Area (sq. m) | Coefficient of Thermal Expansion (x10-6/℃) | Weight (kg/m) |

|---|---|---|---|---|---|

| DB16 | 16 | 35 | 200 | 9-11 | 0.43 |

| DB20 | 20 | 55 | 310 | 9-11 | 0.67 |

| DB25 | 25 | 85 | 490 | 9-11 | 1.05 |

| DB32 | 32 | 130 | 800 | 9-11 | 1.71 |

| DB38 | 38 | 180 | 1130 | 9-11 | 2.41 |

| DB45 | 45 | 255 | 1590 | 9-11 | 3.37 |

The SupAnchor® GFRP Dowel Bar is extensively used in jointed rigid pavement, construction joints, embankments, and mechanically stabilized earth (MSE) walls. Its non-conductive and non-magnetic properties make it particularly valuable in work areas with electromagnetic sensitivities, such as near power lines or in medical facilities. By enabling efficient load transfer and accommodating thermal movements, this product supports the development of resilient infrastructure across Europe and America, from highways to urban projects. In contexts where self drilling anchor bolts and hollow bar anchors are employed for geotechnical reinforcement, the dowel bar complements these systems by ensuring joint stability in concrete structures.

The adoption of SupAnchor's GFRP Dowel Bar contributes significantly to global infrastructure, tunneling, mining, and geotechnical safety initiatives. Its long service life and corrosion resistance reduce environmental impact and maintenance demands, aligning with sustainable construction practices. As part of a broader geotechnical reinforcement system, including drill-and-grout bolts and soil nail systems, this product enhances the reliability of critical projects. SupAnchor's innovation in this area addresses the growing need for durable materials in aging infrastructure, supporting economic growth and public safety in regions with varying climatic and geological challenges.

SupAnchor® has established itself as a professional and innovative leader in the construction industry, with a strong focus on research and development. The company holds ISO certifications and has successfully implemented its products in global projects, from European transportation networks to American urban developments. By offering customized solutions like the GFRP Dowel Bar, SupAnchor demonstrates a collaborative approach, working closely with engineers and contractors to meet specific needs. This commitment extends to their portfolio of self drilling anchor systems and other geotechnical reinforcement products, ensuring comprehensive support for modern construction demands.

In conclusion, the SupAnchor® GFRP Dowel Bar represents a key advancement in construction technology, providing a robust solution for load transfer in concrete slabs. Its technical features, wide applications, and alignment with SupAnchor's brand values of professionalism, innovation, and collaboration make it a valuable asset for infrastructure projects worldwide. As the industry continues to evolve, products like this dowel bar, alongside self drilling anchor bolts and other geotechnical systems, will play a crucial role in building safer, more durable environments for future generations.

SupAnchor's self drilling anchor system addresses complex geology in a large-scale project, highlighting innovation in geotechnical engineering for global infrastructure trends.

SupAnchor's Sup2000 and Sup5000 grout pumps, with high delivery rates and robust design, optimize injection work in tunneling, civil engineering, and mining applications worldwide.

A large-scale tunnel project in Europe utilizes SupAnchor's self-drilling anchor bolts to overcome complex geology, improving infrastructure safety and efficiency.

SupAnchor introduces the GFRP SDA Bolt, an innovative self drilling anchor system that integrates drilling, grouting, and anchoring for fast installation in soft rock and clay soil, improving safety and efficiency in global infrastructure projects.

SupAnchor's advanced self drilling anchor bolt system provides critical support in a challenging Alpine tunneling project, showcasing innovation in geotechnical reinforcement systems for global infrastructure.