In a significant advancement for infrastructure development, a major tunneling project in Central Europe is leveraging SupAnchor's cutting-edge self drilling anchor system to overcome complex geological challenges. This project, set in a region with mixed soil and rock formations, requires robust foundation support to ensure long-term stability and safety. SupAnchor, a leading geotechnical reinforcement system provider, is playing a pivotal role by deploying its innovative hollow bar anchor technology, which integrates drilling and grouting in a single operation, reducing installation time and enhancing structural integrity.

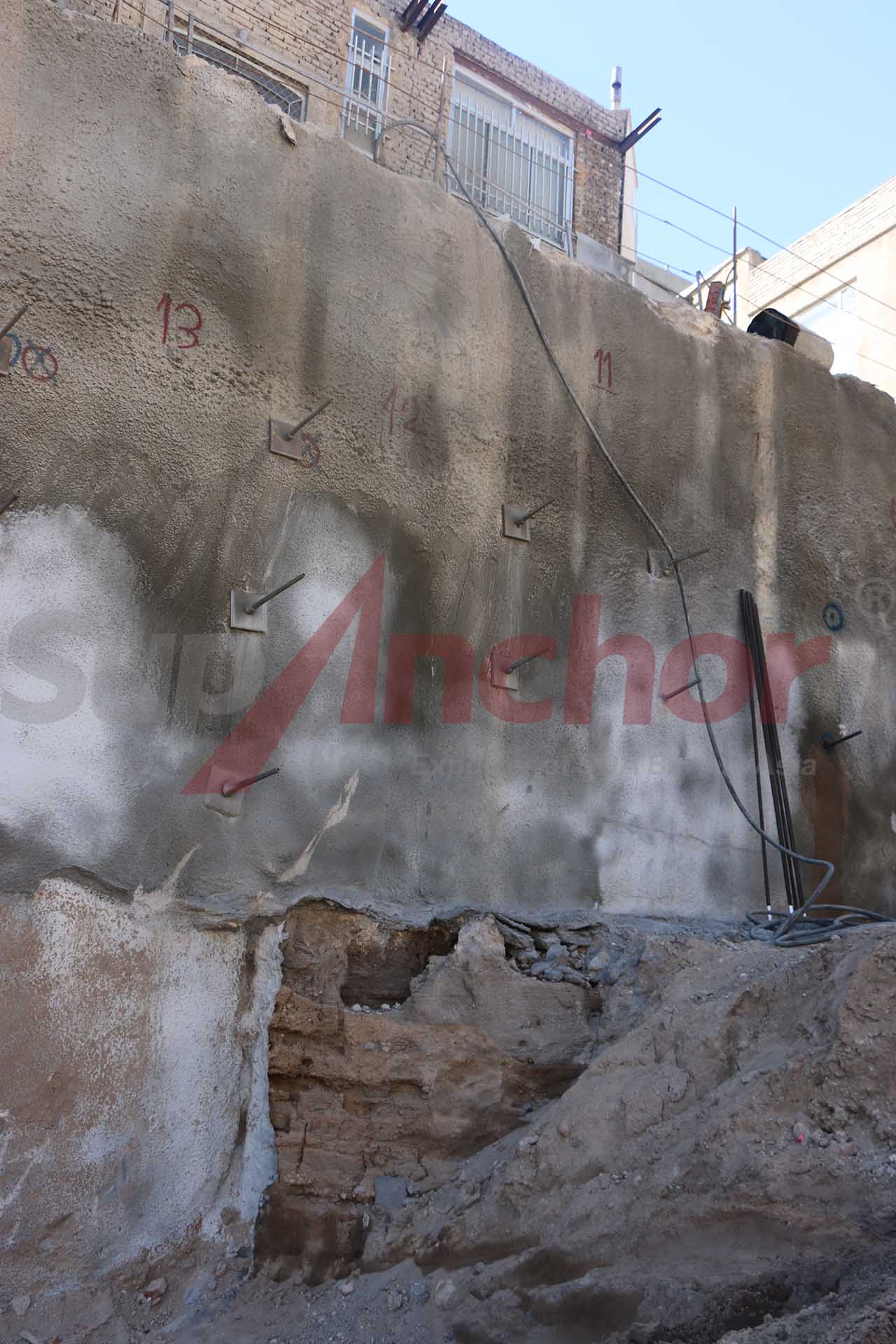

The construction site image vividly illustrates the installation of SupAnchor's self drilling anchor bolts, showcasing their efficiency in challenging terrains. These bolts are designed as a drill-and-grout bolt solution, offering superior performance in applications such as slope stabilization and retaining walls. Key technical specifications, derived from SupAnchor's product line, address site-specific issues like soft soil penetration and high tensile loads.

| Parameter | Value | Application Benefit |

|---|---|---|

| Tensile Strength | 600 MPa | Ensures durability under high stress in tunneling and mining. |

| Diameter | 25 mm | Optimal for precision in geotechnical reinforcement systems. |

| Length | Up to 12 m | Allows deep anchoring in variable soil conditions for ground stabilization. |

| Corrosion Protection | Epoxy Coating | Extends lifespan in harsh environments, ideal for civil engineering projects. |

| Installation Method | Self-Drilling with Grout Injection | Reduces labor and time, enhancing efficiency for SDA bolt factory direct supply. |

These parameters enable the self drilling anchor system to provide reliable support, mitigating risks such as ground movement and ensuring the project meets stringent safety standards. The use of micropile hollow bar anchors in this context highlights SupAnchor's adaptability as a soil nail system manufacturer, offering tailored solutions for diverse geotechnical needs.

The adoption of SupAnchor's self drilling anchor bolt aligns with global trends in infrastructure development, where urbanization and transportation expansion drive demand for advanced geotechnical solutions. Projects like this tunnel are part of a broader movement toward sustainable construction, emphasizing geotechnical safety and efficiency. The ground anchor bolt factory expertise of SupAnchor supports this by providing rock bolts for underground mining and other applications, contributing to resilient infrastructure worldwide.

In Europe and North America, there is a growing focus on retrofitting aging structures and building new ones with enhanced reinforcement systems. SupAnchor's self drilling anchor for retaining walls and ground stabilization anchor system are instrumental in this shift, offering cost-effective and reliable options. As a self drilling bolt for civil engineering specialist, the company addresses key challenges in tunneling and slope stabilization, pushing the industry toward innovative practices.

SupAnchor stands out as a professional leader in the geotechnical sector, with ISO 9001 certifications underscoring its commitment to quality and innovation. The company's collaborative approach involves partnering with global engineering firms to deploy its anchor bolt system for geotechnical engineering, ensuring projects benefit from cutting-edge technology and expert support. Their self drilling anchor system exemplifies this by integrating research-driven designs with practical on-site applications.

Innovation is at the core of SupAnchor's ethos, as seen in their development of hollow bar anchors that streamline installation processes. By offering SDA bolt factory direct supply, they maintain control over production standards, delivering products that meet the highest specifications for durability and performance. This commitment extends to global projects, where SupAnchor's ground stabilization anchor system has been used in diverse environments, from urban developments to remote mining sites.

In summary, SupAnchor's self drilling anchor system is setting new benchmarks in geotechnical engineering, driven by a focus on professionalism, innovation, and collaboration. As infrastructure demands grow, their solutions, including the self drilling anchor bolt and related geotechnical reinforcement systems, will continue to play a vital role in ensuring safety and sustainability across the construction industry.

SupAnchor's self drilling anchor system addresses complex geology in a large-scale project, highlighting innovation in geotechnical engineering for global infrastructure trends.

SupAnchor's Sup2000 and Sup5000 grout pumps, with high delivery rates and robust design, optimize injection work in tunneling, civil engineering, and mining applications worldwide.

A large-scale tunnel project in Europe utilizes SupAnchor's self-drilling anchor bolts to overcome complex geology, improving infrastructure safety and efficiency.

SupAnchor introduces the GFRP SDA Bolt, an innovative self drilling anchor system that integrates drilling, grouting, and anchoring for fast installation in soft rock and clay soil, improving safety and efficiency in global infrastructure projects.

SupAnchor's advanced self drilling anchor bolt system provides critical support in a challenging Alpine tunneling project, showcasing innovation in geotechnical reinforcement systems for global infrastructure.