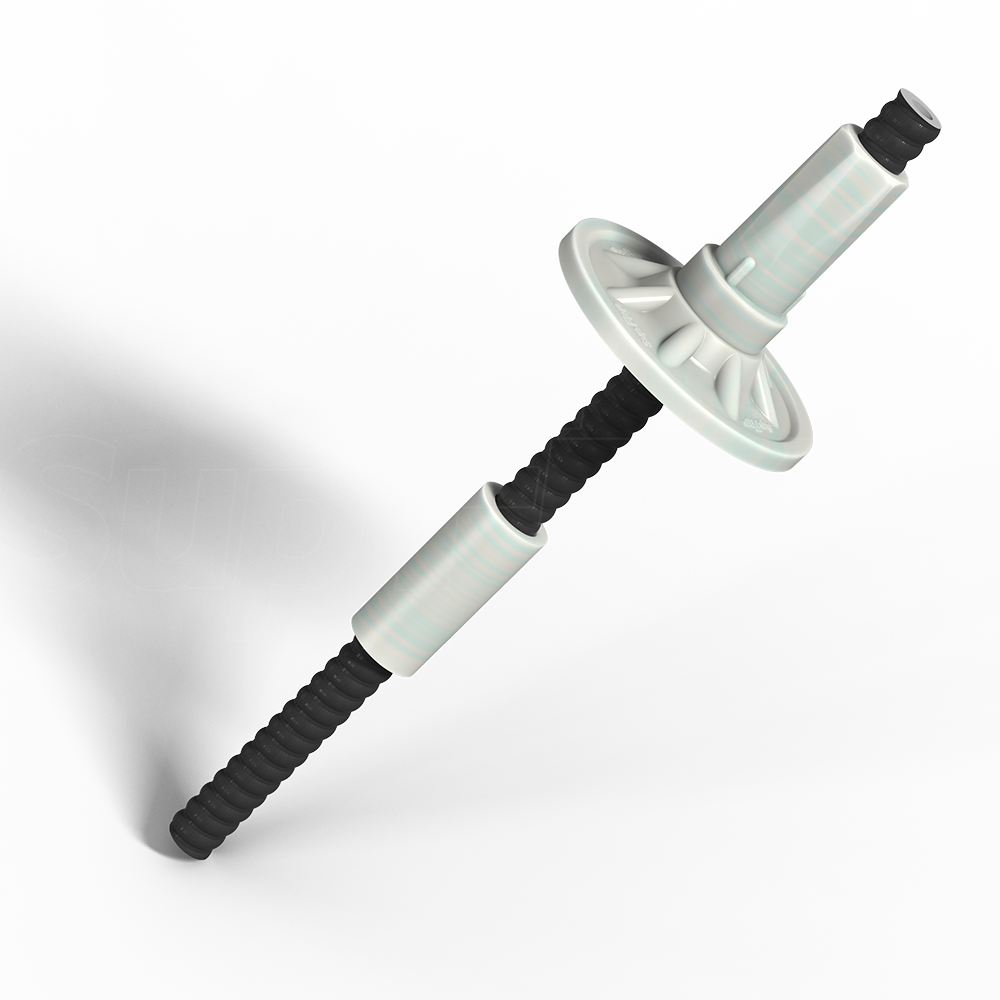

In the ever-evolving field of geotechnical engineering, projects across Europe and America are increasingly confronted with complex geological challenges, from unstable slopes in mountainous regions to high-pressure tunneling operations. SupAnchor, a prominent player in the industry, has responded with its SupFRP® GFRP Hollow Injection Bolt, a core product designed to integrate rock bolting and injection grouting functions. This innovation is set to transform how engineers approach reinforcement in demanding environments, ensuring safety and durability in infrastructure development.

The self drilling anchor system operates by allowing grouting material to be injected through the hollow core, after which the bolt remains securely in place to bear loads alongside end plates and nuts. This process not only streamlines installation but also enhances bonding with various grouting materials, thanks to high injection pressures that achieve full grouting. Applications span slope stabilization, TBM face support, forepoling, and confined ground conditions, making it versatile for both temporary and permanent uses in geotechnical projects.

SupAnchor's hollow bar anchor is engineered with key features that address specific site needs. It offers high tensile load capacities, excellent pressure resistance, low weight for easy handling, cuttability for adjustments, high corrosion resistance, and strong bond forces. These attributes are critical in solving challenges like load-bearing in soft rock or preventing corrosion in harsh mining environments. For instance, in tunneling, the bolt's ability to withstand high stresses ensures reliable support during excavation, while its lightweight nature reduces labor costs and installation time.

To highlight the performance, here are technical data for selected models, showcasing the diversity of options available:

| Model | Guaranteed Tensile Load (kN) | Pressure Resistance (MPa) | Weight (kg/m) | Outside Diameter (mm) |

|---|---|---|---|---|

| H25/220 | 220 | 5 | 0.64 | 25 |

| H28/320 | 320 | 5 | 0.88 | 28 |

| H32/360 | 360 | 5 | 1.20 | 32 |

| H22/230 | 230 | 18 | 0.58 | 22 |

These specs demonstrate how the geotechnical reinforcement system adapts to varying project requirements. For example, the H22/230 model's higher pressure resistance of 18 MPa makes it ideal for applications where grouting pressures are elevated, such as in deep mining shafts. The bolt's design, including waved thread structures and customizable lengths from 2 to 11 meters, provides engineers with flexibility to tailor solutions for specific site conditions, enhancing overall project quality and safety.

The drill-and-grout bolt is making significant strides in global infrastructure sectors. In Europe and America, where aging infrastructure and new developments demand robust solutions, SupAnchor's product is being adopted for tunneling projects, such as metro expansions and highway tunnels, where TBM face support is crucial. For slope stabilization, it secures unstable terrains in regions prone to landslides, contributing to environmental safety. In mining, its corrosion resistance ensures longevity in acidic or wet conditions, reducing maintenance costs and downtime.

This self drilling anchor bolt aligns with industry trends toward sustainable and efficient construction methods. By improving load-bearing capacities and reducing installation times, it helps projects meet tight deadlines and budget constraints. The geotechnical reinforcement system is also gaining traction in emerging markets, where rapid urbanization requires reliable ground anchor solutions for high-rise buildings and transportation networks.

SupAnchor's commitment to research and development underpins the success of its hollow injection bolt. With ISO certifications and a focus on innovation, the brand has established itself as a leader in the geotechnical products market. Their collaborative approach involves working closely with engineers and contractors globally to refine products based on real-world feedback, ensuring that solutions like the self drilling anchor system are both professional and practical.

The brand's message of being professional, innovative, and collaborative is reflected in their global projects, from major tunneling initiatives in Europe to slope stabilization efforts in North America. By investing in advanced materials like GFRP, which offers superior strength-to-weight ratios, SupAnchor continues to push boundaries in geotechnical engineering. This dedication not only enhances their reputation as a reliable ground anchor bolt factory but also sets new standards for the industry.

In summary, SupAnchor's GFRP Hollow Injection Bolt represents a pivotal advancement in geotechnical reinforcement technology. Its combination of high performance, adaptability, and brand excellence makes it a valuable asset for engineers worldwide, driving safer and more efficient infrastructure development. As the demand for innovative solutions grows, products like this are poised to play a central role in shaping the future of construction and mining industries.

SupAnchor's self drilling anchor system addresses complex geology in a large-scale project, highlighting innovation in geotechnical engineering for global infrastructure trends.

SupAnchor's Sup2000 and Sup5000 grout pumps, with high delivery rates and robust design, optimize injection work in tunneling, civil engineering, and mining applications worldwide.

A large-scale tunnel project in Europe utilizes SupAnchor's self-drilling anchor bolts to overcome complex geology, improving infrastructure safety and efficiency.

SupAnchor introduces the GFRP SDA Bolt, an innovative self drilling anchor system that integrates drilling, grouting, and anchoring for fast installation in soft rock and clay soil, improving safety and efficiency in global infrastructure projects.

SupAnchor's advanced self drilling anchor bolt system provides critical support in a challenging Alpine tunneling project, showcasing innovation in geotechnical reinforcement systems for global infrastructure.