In the rugged terrains of European infrastructure projects, engineers frequently encounter unstable geological conditions that threaten construction timelines and worker safety. SupAnchor has responded with its SupFRP® GFRP Hollow Injection Bolt, a core product designed to integrate rock bolting and injection functions for superior performance in challenging environments. This innovation is pivotal for projects involving slope stabilization, tunneling, and other geotechnical applications, where reliability and efficiency are paramount.

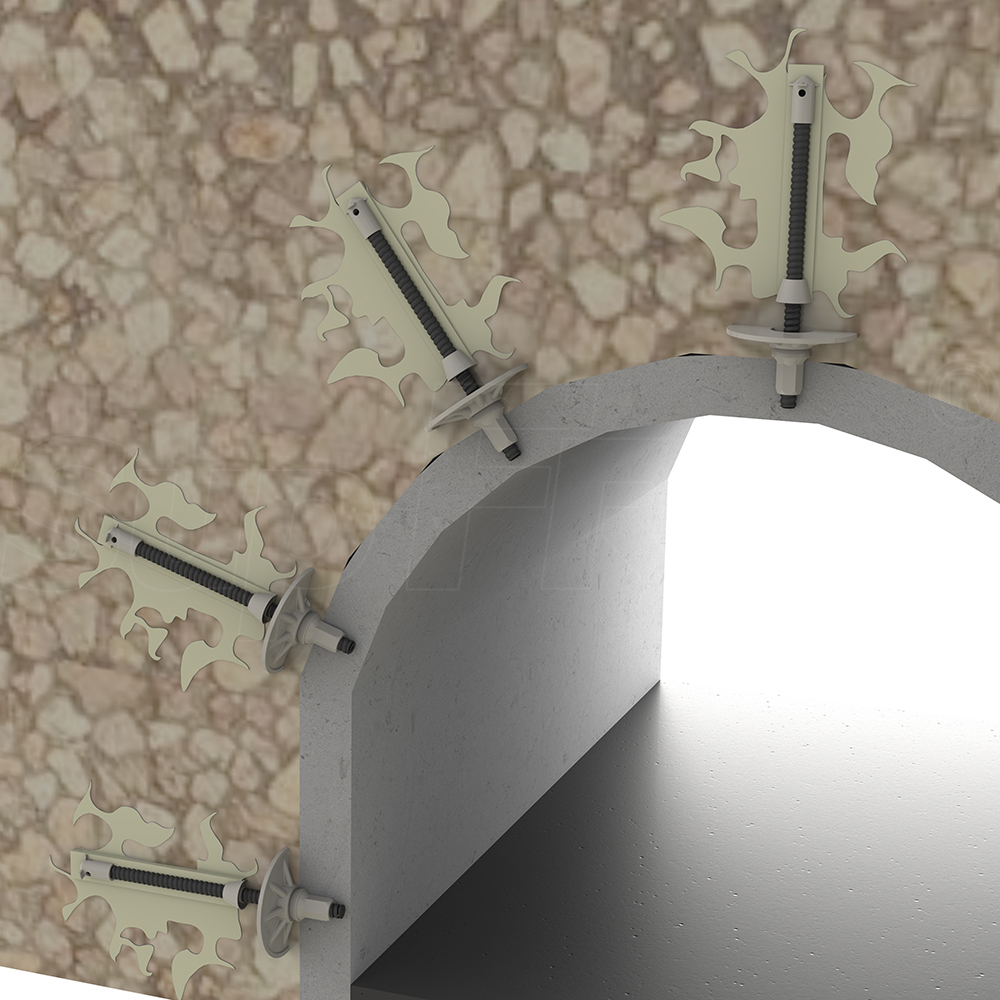

The SupAnchor GFRP hollow injection bolt addresses critical engineering needs by combining high tensile load with pressure resistance, enabling full grouting and strong bonding with various materials. On-site, the process involves drilling the bolt into boreholes, followed by high-pressure injection of grout, which ensures complete filling and enhanced structural integrity. This self drilling anchor system mitigates risks in unstable grounds, such as rock falls or soil shifts, by providing durable support.

| Model | Outside Diameter (mm) | Tensile Load (kN) | Pressure Resistance (MPa) | Weight (kg/m) |

|---|---|---|---|---|

| H25/220 | 25 | 220 | 5 | 0.64 |

| H28/320 | 28 | 320 | 5 | 0.88 |

| H32/360 | 32 | 360 | 5 | 1.20 |

| H38/490 | 38 | 490 | 5 | 1.5 |

| H22/230 | 22 | 230 | 18 | 0.58 |

| H25/300 | 25 | 300 | 30 | 0.79 |

Key parameters like tensile load and pressure resistance directly combat engineering challenges; for example, the high tensile strength prevents bolt failure under stress, while the lightweight design simplifies handling in confined spaces. The hollow bar anchor's cuttability and corrosion resistance further extend its lifespan, reducing maintenance in harsh environments. This geotechnical reinforcement system exemplifies how advanced materials can solve real-world problems, such as in TBM face support where rapid deployment is essential.

The versatility of the SupAnchor self drilling anchor bolt makes it ideal for diverse applications, enhancing safety and efficiency. In slope stabilization, it prevents landslides by securing unstable earth, while in tunneling, it provides critical support for tunnel boring machines. Other uses include forepoling for temporary excavation support and permanent installations in soft rock or confined grounds. This drill-and-grout bolt technology ensures that projects meet stringent safety standards, particularly in urban developments and mining operations where ground stability is non-negotiable.

These applications highlight the product's adaptability, making it a go-to solution for engineers dealing with variable ground conditions. The self drilling anchor system's ability to integrate seamlessly with existing workflows underscores its value in modern geotechnical projects.

Globally, the demand for robust geotechnical solutions is rising with increased infrastructure investments in tunneling, mining, and urban development. SupAnchor's GFRP hollow injection bolt contributes significantly by enhancing safety through its high load-bearing capacity and durability. In Europe and North America, where regulations emphasize worker protection and environmental sustainability, this product helps projects comply with standards while minimizing risks of accidents. The geotechnical reinforcement system not only speeds up construction but also reduces long-term costs by preventing failures and extending structure lifespans. As industries shift towards safer practices, innovations like the hollow bar anchor are setting new benchmarks for reliability and efficiency in ground stabilization.

SupAnchor's commitment to professionalism and innovation is evident in its extensive research and development efforts, which have led to breakthroughs like the GFRP hollow injection bolt. The company holds ISO certifications, ensuring high-quality standards across its product lines, and has successfully deployed its solutions in major global projects, from alpine tunnels to coastal stabilizations. By collaborating closely with engineers and contractors, SupAnchor tailors its offerings to specific needs, fostering a culture of innovation and teamwork. This approach has solidified its reputation as a leader in the geotechnical sector, driving advancements that benefit infrastructure worldwide. The self drilling anchor bolt, in particular, reflects SupAnchor's dedication to creating sustainable, effective tools for the industry.

Looking ahead, SupAnchor continues to pioneer geotechnical reinforcement systems that address evolving challenges, reinforcing its role as a trusted partner in building safer, more resilient infrastructure. Through ongoing innovation and global collaboration, the company aims to set new standards in engineering excellence.

Explore how SupAnchor's self drilling anchor bolt system tackles complex geology in infrastructure, ensuring robust ground stabilization and safety in European projects.

SupAnchor's GFRP hollow injection bolt provides high tensile strength and corrosion resistance, improving safety in slope stabilization and tunneling applications.

An in-depth report on SupAnchor's self drilling anchor bolts used in challenging geotechnical conditions, highlighting technical specs and industry impact on infrastructure safety.

SupAnchor introduces the GFRP Solid Bolt, featuring high tensile strength and corrosion resistance for reliable use in slopes, tunnels, and mines, improving safety and efficiency in geotechnical projects.

Exploring how SupAnchor's self drilling anchor bolts provide geotechnical reinforcement in highway construction, addressing challenges like slope stability and soil erosion for safer infrastructure.