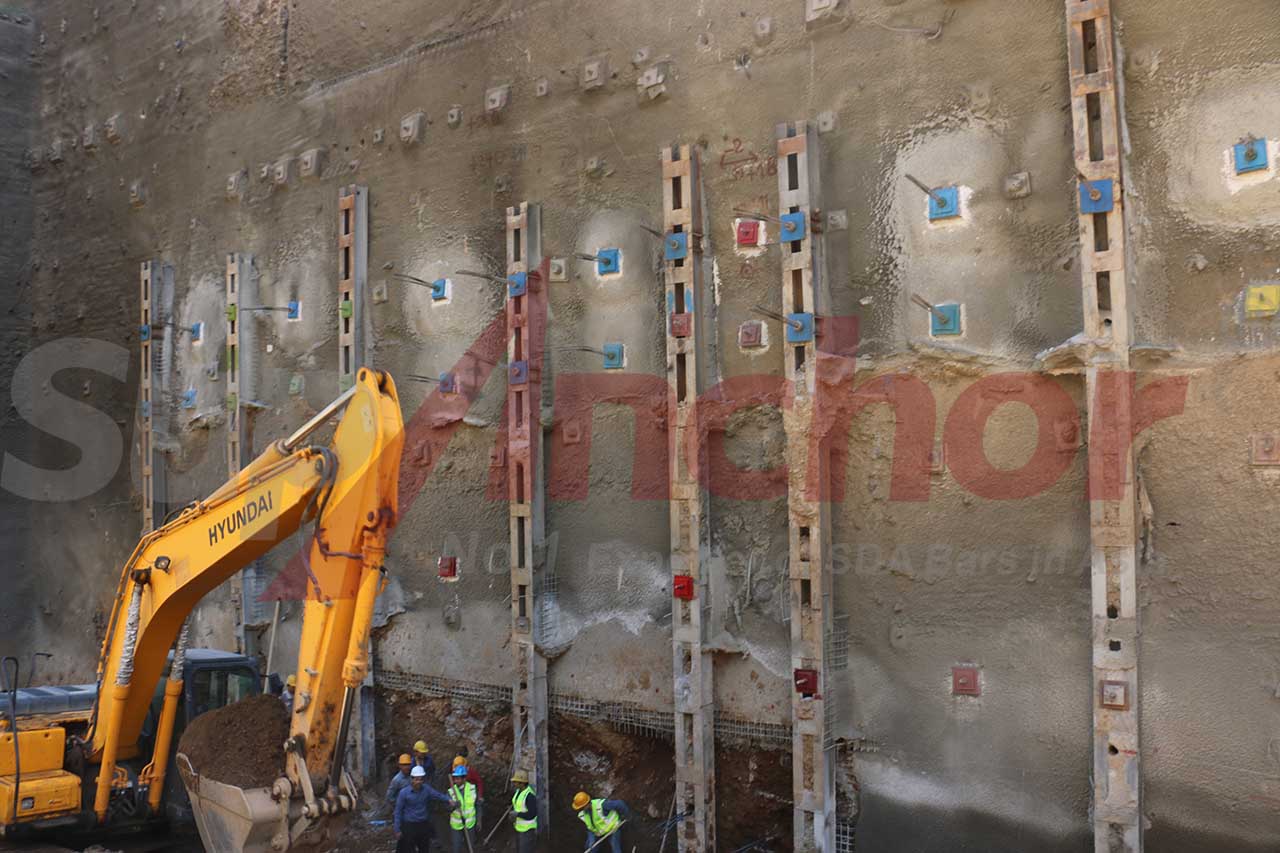

In the dynamic construction industry, particularly across Europe and North America, projects often face challenges such as harsh geological conditions, tight schedules, and increasing demands for sustainability. SupAnchor, a prominent innovator in geotechnical reinforcement systems, has responded with the launch of the SupFRP® GFRP Tie Rod. This specialized product is engineered for formwork applications, offering a permanent alternative to traditional steel rods. By eliminating the need for removal after project completion, it significantly reduces transportation and storage costs, aligning with modern construction efficiencies. The development underscores SupAnchor's role in providing solutions that address both engineering and economic concerns in large-scale infrastructure projects, from urban developments to tunneling and mining operations.

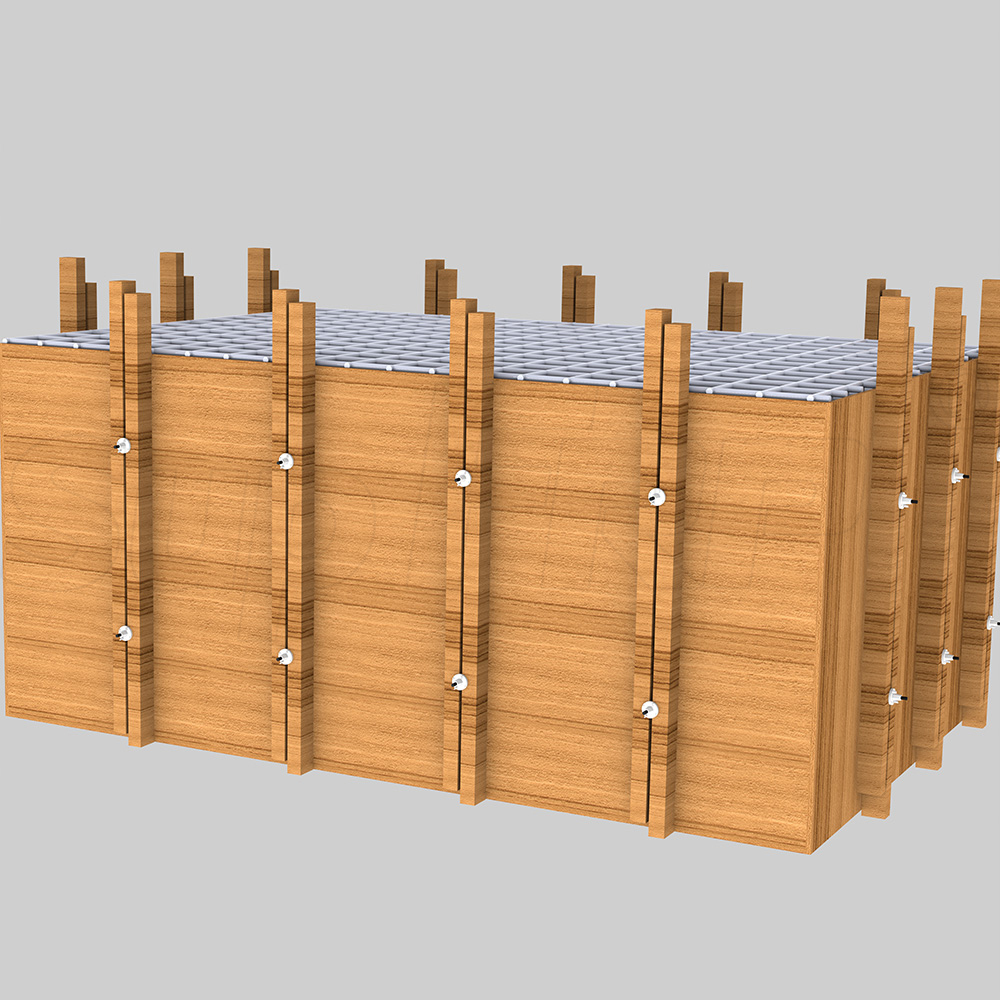

The SupAnchor GFRP Tie Rod is meticulously designed to match the thread profile of standard steel rods, ensuring compatibility with existing accessories and simplifying integration into diverse construction workflows. Key technical features include high tensile strength, exceptional corrosion resistance, and lightweight properties, which collectively enhance performance and ease of handling. Below is a detailed comparison of the two available models, highlighting critical parameters that address common engineering challenges:

| Parameter | T15/130 | T20/250 |

|---|---|---|

| Outside Diameter (mm) | 17 | 22 |

| Nominal Cross Sectional Area (sq. mm) | 130 | 250 |

| Guaranteed Tensile Load (kN) | 130 | 250 |

| Tensile E-Modulus (GPa) | 45 | 45 |

| Ultimate Strain (%) | 2.0 | 2.0 |

| Weight (kg/m) | 0.37 | 0.71 |

| Available Lengths (m) | 1 to 11 | 1 to 11 |

These specifications are tailored to solve engineering challenges in formwork, such as reducing labor-intensive removal processes and mitigating corrosion in aggressive environments. For instance, the high tensile load capacity ensures structural integrity, while the non-conductive and non-magnetic properties enhance safety in electrical applications or near sensitive equipment. The product's cuttability and ease of handling further streamline on-site operations, making it a versatile choice for various construction scenarios.

The SupAnchor GFRP Tie Rod is primarily designed for formwork applications in concrete structures, but its advantages extend to broader geotechnical reinforcement systems. In tunneling and mining projects, where durability and safety are paramount, this tie rod offers a reliable solution that minimizes maintenance and replacement costs. Its permanent application reduces waste and supports sustainable construction practices, which are increasingly prioritized in global infrastructure development.

SupAnchor's expertise in self drilling anchor systems and other products, such as hollow bar anchors and drill-and-grout bolts, complements this launch. The GFRP tie rod can be integrated with existing geotechnical solutions, enhancing overall project efficiency. For example, in projects requiring ground anchor bolts or soil nail systems, the tie rod provides a corrosion-resistant alternative that aligns with long-term performance goals. This adaptability positions SupAnchor as a key player in advancing construction technologies across industries.

The introduction of the GFRP Tie Rod reflects SupAnchor's commitment to innovation and collaboration in the construction sector. As a manufacturer with ISO certifications and a portfolio that includes self drilling anchor bolts and geotechnical reinforcement systems, SupAnchor has built a reputation for professional and reliable solutions. The company's involvement in global projects, from urban skyscrapers to underground tunnels, demonstrates its ability to address complex engineering needs.

This product contributes to industry value by promoting cost-effective and environmentally friendly construction methods. By reducing the reliance on steel and minimizing post-construction work, it supports trends toward infrastructure longevity and safety. SupAnchor's R&D efforts continue to drive advancements, ensuring that their products meet evolving market demands while conveying a brand message of professionalism, innovation, and collaboration.

For further insights, users are encouraged to view the demonstration video available on SupAnchor's website, which showcases practical applications of the GFRP Tie Rod in real-world settings. This resource highlights how the product integrates seamlessly into construction workflows, reinforcing SupAnchor's role as a leader in geotechnical solutions.

A European infrastructure project overcomes soil instability with SupAnchor's self drilling anchor system, highlighting innovation in geotechnical reinforcement for tunneling and slope stabilization.

SupAnchor introduces a GFRP tie rod for formwork, featuring high corrosion resistance, permanent installation, and cost savings, supporting sustainable construction practices in global infrastructure.

A major infrastructure project in Europe leverages SupAnchor's self drilling anchor bolts for slope stabilization and foundation support in complex geological conditions.

SupAnchor launches an innovative GFRP self-drilling anchor bolt that integrates drilling, grouting, and anchoring, offering efficient solutions for soft rock and clay soil stabilization in tunneling and slope projects.

SupAnchor's self drilling anchor bolts provide critical geotechnical reinforcement in challenging projects, improving safety and efficiency for global infrastructure.