As global infrastructure projects expand into more complex terrains, the mining and tunneling industries face heightened challenges from unstable rock formations and demanding safety standards. In response, SupAnchor, a leading manufacturer of self drilling anchor systems, has launched the SupHulk friction rock bolt system, designed to offer reliable and efficient reinforcement. This innovation addresses critical engineering needs by providing immediate load-bearing capacity and adaptability, ensuring enhanced safety and performance in diverse applications.

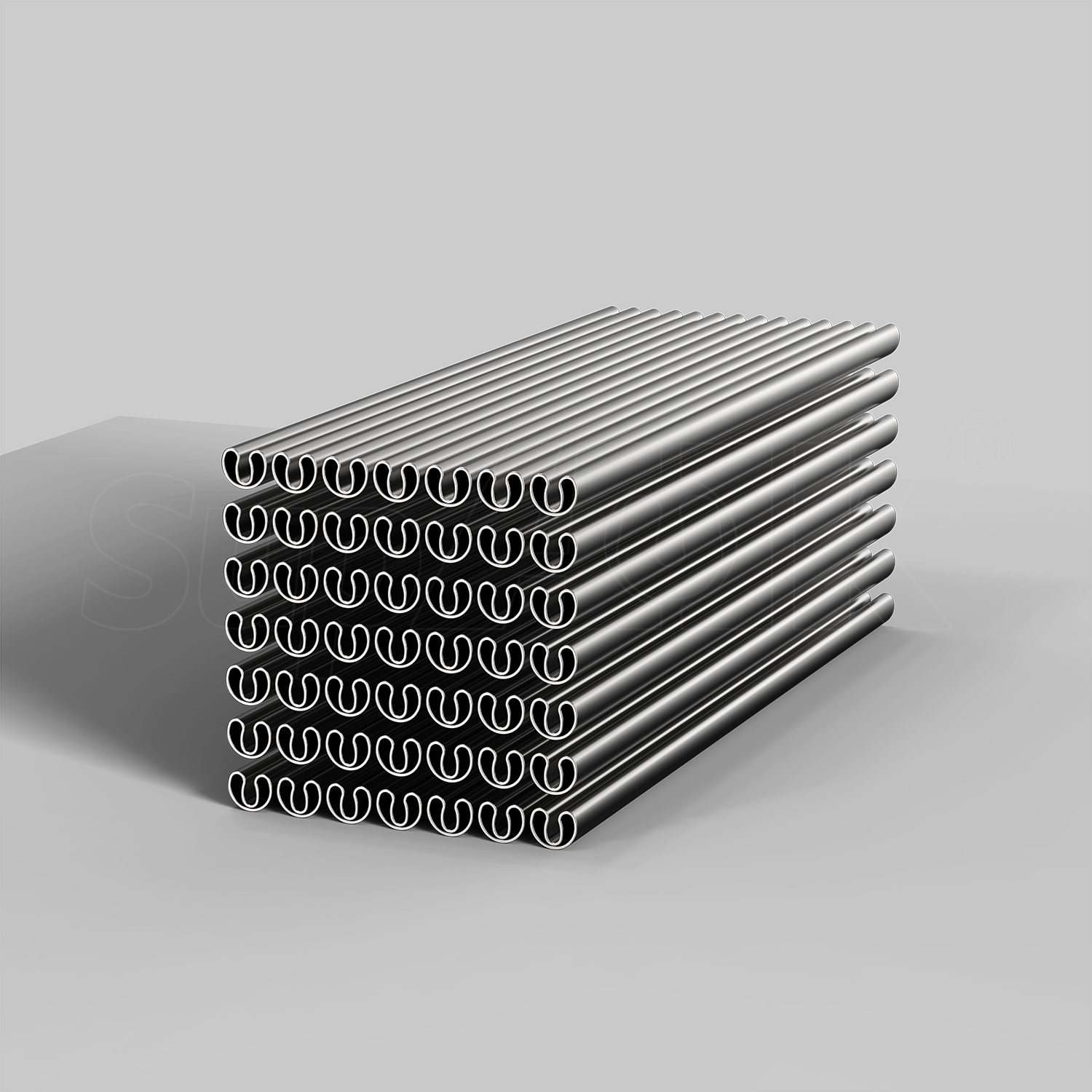

The SupHulk system is engineered for rock strengthening in mining and tunneling construction, utilizing friction between the expanded bolt and rock to achieve full-column support along the entire borehole length. This mechanism allows the bolt to bear full loads directly after installation and absorb rock movements immediately, making it ideal for rapid deployment in high-risk environments.

The installation process of the SupHulk rock bolt is straightforward, involving drilling a hole, inserting the bolt, and inflating it to a pre-determined pressure with a specialized system. This simplicity enhances on-site efficiency while maintaining quality, as the pump automatically stops at the recommended pressure. Key parameters from the Premium line (PM) series highlight its robust performance:

| Model | Minimum Breaking Load (kN) | Minimum Yield Load (kN) | Inflation Pressure (bar) | Hole Diameter Range (mm) |

|---|---|---|---|---|

| PM12 | 110 | 100 | 300 | 32-39 |

| PM16 | 160 | 130 | 240 | 43-52 |

| PM24 | 240 | 200 | 300 | 43-52 |

These specifications enable the SupHulk bolt to handle high-stress conditions, with breaking loads up to 240 kN and elongation of at least 10% for durability. The system's ability to adapt to borehole irregularities and bridge gaps in rock ensures reliable support in varied geological settings, solving engineering challenges like shear movements and instability.

SupHulk rock bolts are highly versatile, suitable for both mining and civil engineering projects. In tunneling, they serve as pattern bolts for excavation support, with bolting patterns tailored to rock mass properties. In mining, common applications include roof bolting and hanging wall bolting, where their rapid installation and high performance improve safety by mitigating rockfall risks.

This geotechnical reinforcement system is critical for global infrastructure, supporting projects in Europe and America where safety regulations are stringent. By providing friction and inter-locking support, SupHulk bolts enhance the stability of tunnels and mines, contributing to reduced accidents and operational delays.

SupAnchor's commitment to research and development underpins the SupHulk system, reflecting their professional, innovative, and collaborative brand message. With ISO certifications and a focus on global projects, SupAnchor ensures that their self drilling anchor bolt solutions meet international standards. The company's expertise in hollow bar anchor technology and drill-and-grout bolt alternatives further solidifies their market leadership.

Specific applications, such as radial systematic anchoring in tunneling and reinforcement in mining, demonstrate SupAnchor's role in advancing geotechnical safety. The SupHulk system, part of their comprehensive product range, underscores their influence as a trusted partner in the construction and mining sectors.

In summary, the SupHulk friction rock bolt system by SupAnchor represents a significant advancement in self drilling anchor systems. By combining high technical specs with ease of use and broad applicability, it addresses critical challenges in mining and tunneling, promoting safety and efficiency on a global scale. As infrastructure demands grow, solutions like the SupHulk bolt will continue to play a pivotal role in shaping a safer and more resilient built environment, supported by SupAnchor's ongoing innovation and collaboration with engineering teams worldwide.

SupAnchor's self drilling anchor system provided crucial geotechnical reinforcement for a challenging European infrastructure project, highlighting innovation in ground stabilization and industry trends.

SupAnchor's SupHulk friction rock bolt system provides high-load capacity and immediate support for rock reinforcement in challenging geological conditions, boosting safety in global infrastructure projects.

A major European tunneling project utilizes SupAnchor's innovative self drilling anchor bolt system to overcome challenging soil conditions, ensuring stability and efficiency in construction.

SupAnchor launches a corrosion-resistant self-drilling anchor system for marine and industrial applications, featuring integrated drilling and grouting for long-term stability.

SupAnchor's innovative self drilling anchor bolts and geotechnical reinforcement systems are solving complex challenges in tunneling and slope stabilization projects across Europe.