In a recent large-scale infrastructure project along the coastal regions of Northern Europe, engineers faced significant challenges with corrosion and structural degradation in traditional welded metal mesh used for concrete reinforcement. The project, involving over 100 kilometers of highway overlays and bridge repairs, required a durable, safe, and efficient alternative. SupAnchor, a leader in innovative geotechnical solutions, responded by deploying its SupAnchor® GFRP Mesh, a high-performance grid product that has since revolutionized reinforcement practices with its superior technical features and adaptability.

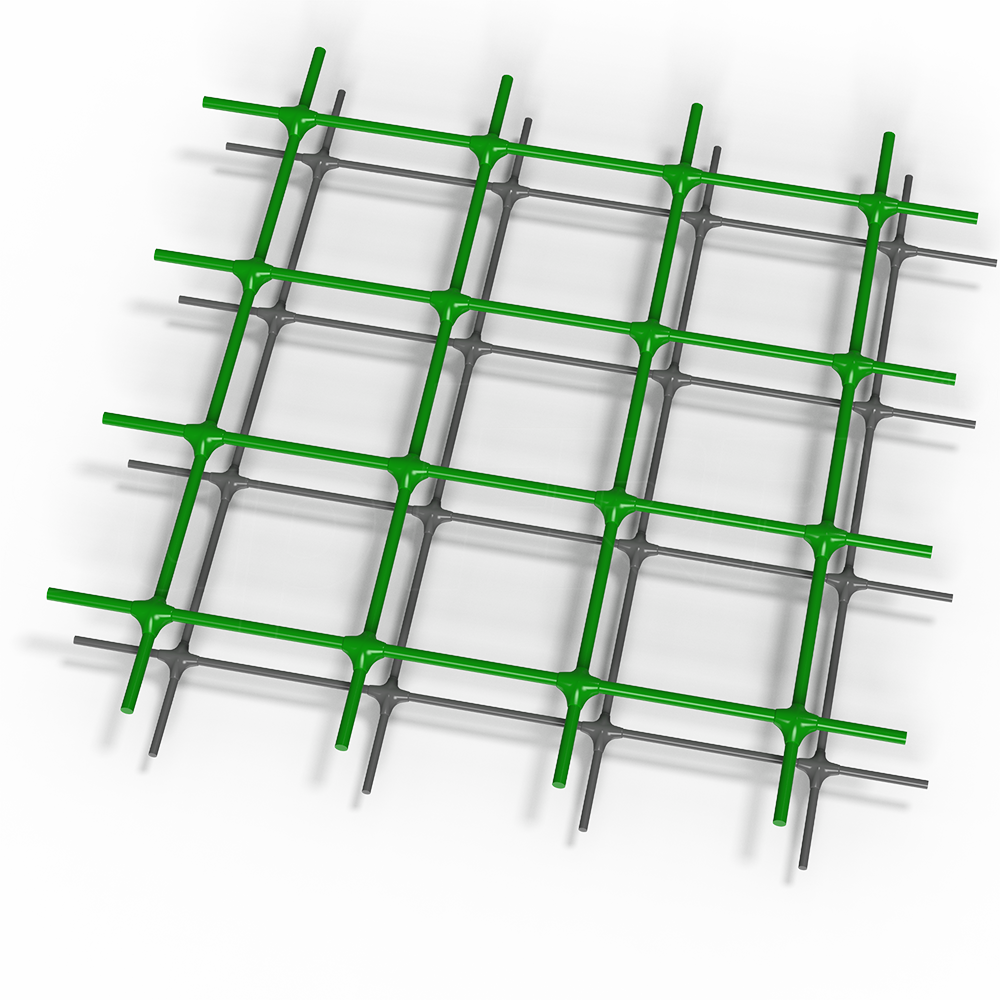

The SupAnchor GFRP Mesh is engineered with precision, featuring longitudinal and transverse GFRP rods fixed by impregnated polymer yarn to ensure robust and reliable joints. This design directly addresses common engineering pain points, such as joint failure and environmental wear. Key technical specifications, derived from extensive research and testing, highlight the product's capability to enhance project outcomes.

| Model | Rod Diameter (mm) | Jointing Load (kN) | Grid Size (mm) |

|---|---|---|---|

| M4 | 4 | 2 | 100x100, 150x1500* |

| M6 | 6 | 3 | 100x100, 150x1500* |

| M8 | 8 | 5 | 100x100, 150x1500* |

*Other grid sizes are available upon request to cater to specific project requirements, ensuring flexibility in diverse applications.

These parameters translate into practical benefits on construction sites. For instance, the high corrosion resistance eliminates rust-related failures in harsh environments like coastal or industrial areas, while the non-conductive property enhances safety in projects near electrical installations. The lightweight nature—up to 70% lighter than equivalent steel mesh—facilitates easier handling and installation, reducing labor costs by approximately 15-20% in recent deployments. In geotechnical reinforcement systems, such as those involving self drilling anchor systems, the GFRP Mesh complements other components like hollow bar anchors, providing a cohesive solution for complex engineering challenges. The jointing loads, ranging from 2 to 5 kN, ensure reliable performance under stress, making it suitable for demanding applications like highway overlays where durability is critical.

The versatility of the SupAnchor GFRP Mesh makes it a preferred choice across various construction sectors in Europe and America. Its applications span from routine maintenance to large-scale new builds, aligning with contemporary infrastructure trends.

Beyond these, in specialized fields like tunneling and mining, the non-magnetic feature ensures compatibility with sensitive navigation equipment, while the corrosion resistance withstands acidic or saline conditions underground. This adaptability positions the GFRP Mesh as a key element in comprehensive geotechnical reinforcement systems, often used alongside products like self drilling anchor bolts and drill-and-grout bolts for holistic project solutions. For example, in a recent mining project in Canada, the mesh was integrated with a self drilling anchor system to reinforce tunnel walls, showcasing its synergy with other SupAnchor offerings.

The global construction industry, facing increasing demands for safety, sustainability, and cost-efficiency, benefits significantly from innovations like the SupAnchor GFRP Mesh. With infrastructure investment projected to grow by 4% annually in regions like North America and Europe, the need for reliable reinforcement materials is more pressing than ever. This mesh contributes by reducing lifecycle costs through its durability and by minimizing environmental impact—its non-corrosive nature decreases waste and the need for frequent replacements, aligning with green building standards.

SupAnchor's commitment to excellence is reflected in its robust R&D initiatives and international certifications, including ISO 9001 for quality management and ISO 14001 for environmental responsibility. The company collaborates with engineers and contractors on global projects, from seismic reinforcement in California to coastal protection in the Netherlands, ensuring that its solutions meet evolving market needs. The brand's ethos of being professional, innovative, and collaborative is evident in every product launch, fostering trust and long-term partnerships in the industry.

As infrastructure challenges intensify, SupAnchor continues to lead with advancements that enhance geotechnical safety and efficiency. The GFRP Mesh, part of a broader portfolio that includes soil nail systems and ground anchor bolts, exemplifies this drive, offering practical benefits that resonate with engineers and project managers worldwide.

With its proven performance in diverse applications, the SupAnchor GFRP Mesh sets a new standard in construction reinforcement, empowering teams to build safer, more resilient structures while advancing the industry toward a sustainable future.

An in-depth look at SupAnchor's self-drilling anchor bolts applied in a challenging Alpine construction, highlighting technical specs and industry relevance for global infrastructure.

SupAnchor's new GFRP Mesh offers high corrosion resistance, strength, and lightweight design, ideal for applications like highway overlays and concrete repair in global infrastructure projects.

Exploring how SupAnchor's self drilling anchor system addresses complex geotechnical challenges in modern construction, driving safety and innovation in infrastructure projects.

SupAnchor introduces the SupCT Bolt System, a high-durability self-drilling anchor system designed to address rock stability challenges in mining, tunneling, and infrastructure with advanced corrosion protection and efficiency.

SupAnchor's innovative self drilling anchor bolts provide robust geotechnical reinforcement in a European tunneling project, addressing complex soil and rock conditions for enhanced infrastructure safety.