In an era where infrastructure durability and safety are paramount, construction projects across Europe and America face significant challenges from thermal expansion, corrosion, and electromagnetic interference. SupAnchor, a leader in geotechnical reinforcement systems, has launched its SupAnchor® GFRP Dowel Bar, designed to address these issues in construction joints for concrete slabs, pavements, and embankments. This innovative product, part of SupAnchor's comprehensive self drilling anchor system portfolio, promises to enhance structural stability and longevity in demanding environments.

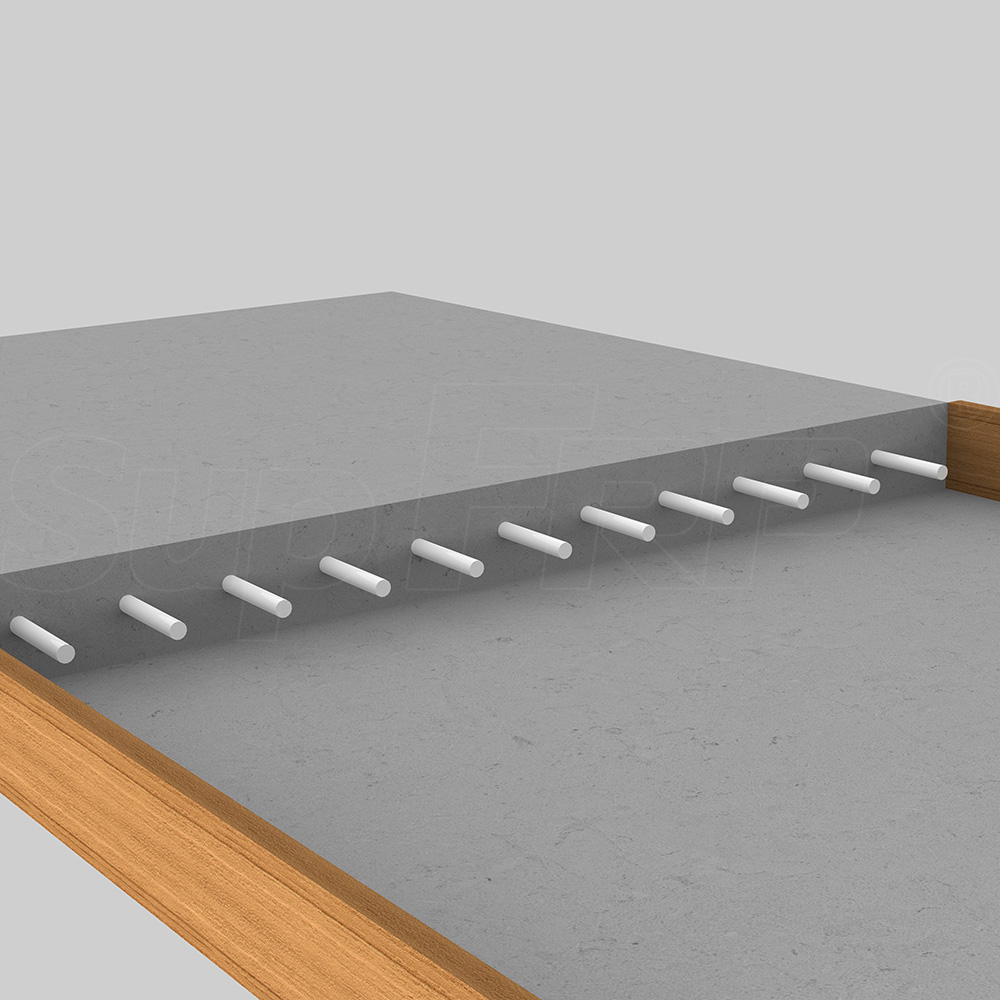

The SupAnchor® GFRP Dowel Bar is engineered from premium glass fiber reinforced polymer (GFRP) raw materials, ensuring high strength and a service life exceeding 100 years. Its primary function is as a load transfer device, mechanically linking adjacent concrete slabs while allowing horizontal movements to accommodate thermal expansion and contraction. This makes it ideal for applications such as jointed rigid pavements, work areas with electromagnetic sensitivities, and MSE walls, where traditional steel dowels might fail due to rust or conductivity issues.

Key technical features include a no-rust design, non-conductive and non-magnetic properties, and superior load transfer efficiency. The product can be customized to meet specific project requirements, highlighting SupAnchor's commitment to adaptability. To illustrate its capabilities, here are selected technical data points for common diameters, presented in a table format for clarity:

| Diameter (mm) | Transverse Shear Load (kN) | Weight (kg/m) | Coefficient of Thermal Expansion (x10-6/℃) |

|---|---|---|---|

| 16 | 35 | 0.43 | 9-11 |

| 20 | 55 | 0.67 | 9-11 |

| 25 | 85 | 1.05 | 9-11 |

| 32 | 130 | 1.71 | 9-11 |

| 38 | 180 | 2.41 | 9-11 |

| 45 | 255 | 3.37 | 9-11 |

These parameters demonstrate how the dowel bar solves engineering challenges by providing reliable shear resistance and thermal compatibility, reducing maintenance needs and improving safety in structures subjected to temperature fluctuations. For instance, in airport runways or highway pavements, the GFRP dowel bar ensures seamless joint performance without conductive interference, aligning with SupAnchor's expertise in drill-and-grout bolt technologies.

The GFRP Dowel Bar is versatile, with main applications including:

This product complements SupAnchor's broader geotechnical reinforcement system, which includes self drilling anchor bolts and hollow bar anchors, offering a holistic solution for soil nailing and ground anchoring. By integrating this dowel bar into projects, engineers can achieve cost savings through reduced corrosion and extended service life, contributing to sustainable infrastructure development in Europe and America.

The introduction of the GFRP Dowel Bar underscores SupAnchor's role in advancing global infrastructure safety and efficiency. With increasing emphasis on resilient construction in mining, tunneling, and urban development, this product addresses key industry needs for non-corrosive, high-performance materials. SupAnchor's commitment to innovation is backed by robust R&D, ISO certifications, and successful implementation in global projects, from earthquake-prone regions to high-traffic transport hubs.

SupAnchor's brand message of being professional, innovative, and collaborative is evident in this launch. The company works closely with clients to customize solutions, ensuring that products like the GFRP Dowel Bar meet specific engineering demands. As part of its self drilling anchor system offerings, this dowel bar reinforces SupAnchor's position as a leading soil nail system manufacturer and ground anchor bolt factory, driving progress in geotechnical engineering.

In summary, the SupAnchor® GFRP Dowel Bar represents a significant leap forward in construction joint technology, offering unparalleled durability and adaptability. By leveraging SupAnchor's expertise in geotechnical reinforcement systems, including self drilling anchor bolts and drill-and-grout bolts, this product is set to transform how infrastructure projects manage thermal and mechanical stresses, paving the way for safer, longer-lasting structures worldwide.

Exploring how SupAnchor's self drilling anchor system provides robust geotechnical reinforcement for challenging construction sites, ensuring stability and safety in modern infrastructure.

SupAnchor unveils its GFRP Dowel Bar, a high-strength, non-corrosive solution for construction joints in pavements and structures, offering over 100 years of service life and superior load transfer efficiency.

A European urban tunneling project leverages SupAnchor's self-drilling anchor systems to address complex geological challenges, advancing geotechnical engineering standards and safety.

SupAnchor launches the Grade 75 self-drilling hollow anchor, a high-strength solution designed to enhance load-bearing capacity in demanding geotechnical engineering applications globally.

Industry report on SupAnchor's self drilling anchor system stabilizing slopes in a complex tunneling project, highlighting technical specs and global geotechnical trends.