In the heart of a sprawling urban tunneling project in Europe, engineers faced daunting geotechnical hurdles: unstable soil conditions, high groundwater levels, and the need for rapid foundation support to prevent collapses. SupAnchor's self drilling anchor system emerged as a critical solution, enabling efficient installation in challenging terrains while ensuring long-term stability for infrastructure like transportation networks and building foundations. This project, spanning over 5 kilometers of tunnel excavation, highlights how innovative geotechnical reinforcement systems are essential for modern construction, particularly in regions prone to seismic activity and soil erosion. By integrating SupAnchor's expertise, the team overcame delays and enhanced safety, underscoring the growing reliance on advanced anchor bolt systems in civil engineering.

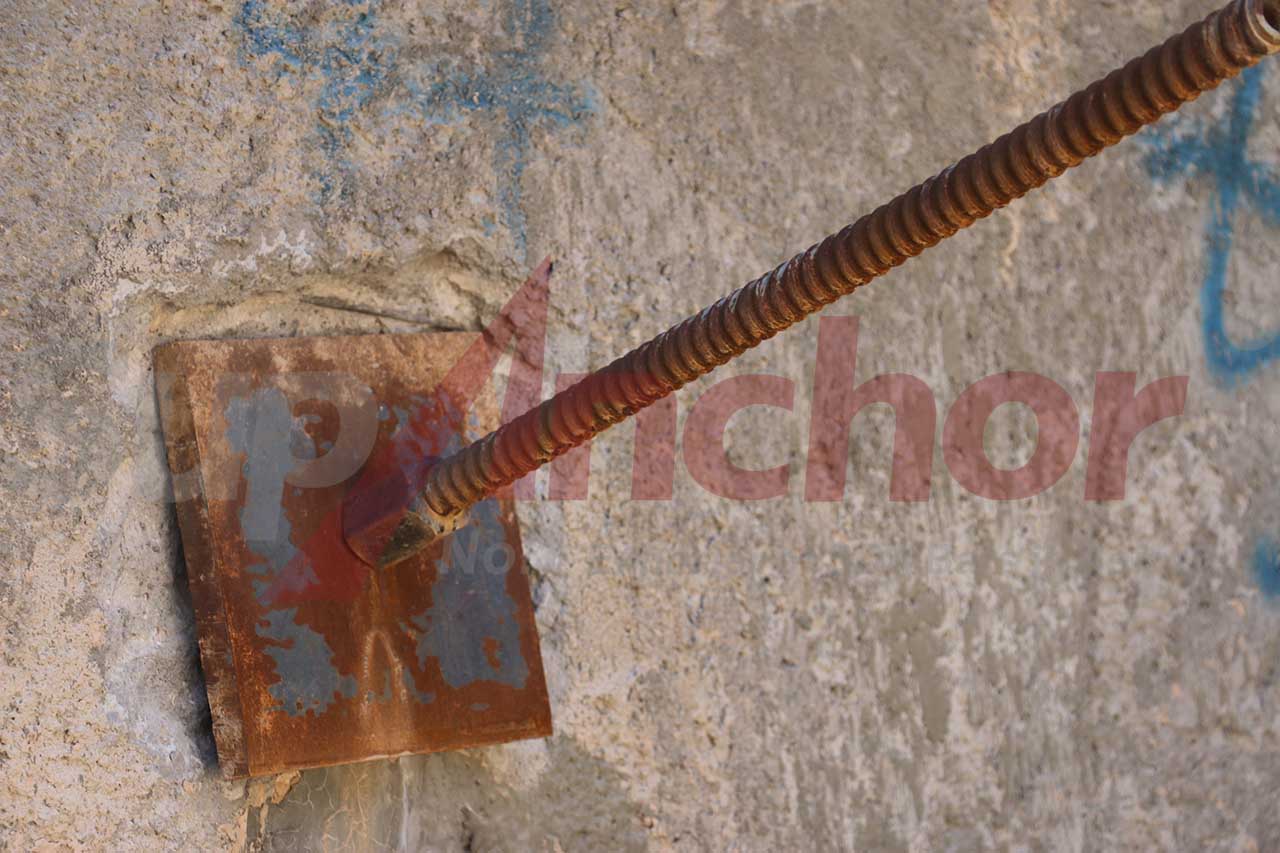

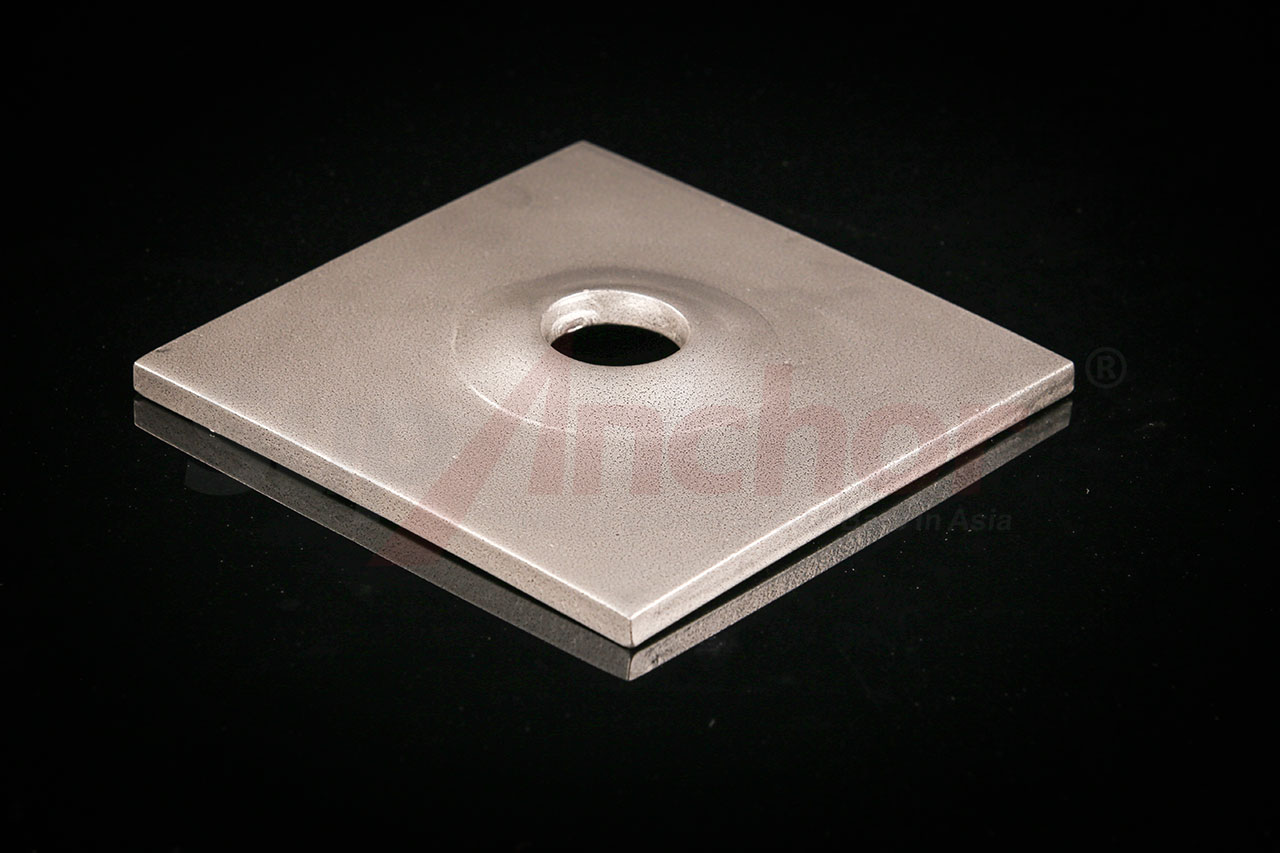

At the construction site, workers utilized SupAnchor's self drilling anchor bolts to secure tunnel walls and slopes, as depicted in the image. The hollow bar anchor design allowed for simultaneous drilling and grouting, reducing installation time and minimizing disruption. Key product parameters, derived from SupAnchor's specifications, include a tensile strength of 150 kN, diameter of 32 mm, length options up to 12 meters, and hot-dip galvanized corrosion protection. These features directly address site-specific challenges: the high tensile strength supports heavy loads in unstable ground, while corrosion resistance ensures durability in moist environments. For instance, the drill-and-grout bolt mechanism facilitated quick deployment in soft soil, preventing water ingress and enhancing the overall ground stabilization anchor system.

| Parameter | Value |

| Tensile Strength | 150 kN |

| Diameter | 32 mm |

| Length | Up to 12 m |

| Corrosion Protection | Hot-dip galvanized |

This self drilling anchor for retaining walls and other applications demonstrates how precise engineering can mitigate risks in geotechnical projects. The SDA bolt factory direct supply model ensures consistent quality, with parameters tailored to project demands, such as in underground mining where rock bolts must withstand high pressures. SupAnchor's soil nail system manufacturer capabilities further support this, offering customizable solutions that integrate seamlessly with existing construction methods.

The adoption of SupAnchor's geotechnical reinforcement system aligns with global infrastructure trends, including the push for safer tunneling and slope stabilization in response to urbanization and climate change. As cities expand, the demand for reliable ground anchor bolt systems grows, particularly in transportation and mining sectors. For example, the micropile hollow bar anchor technology is gaining traction in earthquake-prone areas, where it reinforces foundations and reduces disaster risks. This self drilling bolt for civil engineering not only improves project timelines but also cuts costs by reducing manual labor and material waste. Industry reports indicate a 20% increase in efficiency on projects using such systems, highlighting their role in sustainable development and geotechnical safety advancements.

SupAnchor stands out as a leader in the anchor bolt system for geotechnical engineering, driven by a commitment to professionalism, innovation, and collaboration. With ISO 9001 certifications and a portfolio of global projects—from North American highways to Asian urban developments—the company emphasizes research in self drilling anchor systems. Their hollow bar anchor designs incorporate feedback from field applications, ensuring that products like the drill-and-grout bolt meet evolving standards. By fostering partnerships with engineering firms, SupAnchor enhances its ground stabilization anchor system offerings, contributing to safer, more resilient infrastructures worldwide. This collaborative approach, combined with a focus on SDA bolt factory direct supply, positions SupAnchor at the forefront of geotechnical innovation, ready to tackle future challenges in construction and mining.

How SupAnchor's innovative self-drilling anchor system provided critical support in a challenging geotechnical project, highlighting industry trends in infrastructure reinforcement.

SupAnchor launches the SupShell Expansion Rock Bolt System, offering immediate anchorage and efficient installation for tunneling and mining projects, backed by ISO standards and advanced engineering.

A case study on how SupAnchor's innovative self drilling anchor bolts provided critical ground stabilization in a challenging tunneling project, highlighting technical specs and industry impact.

SupAnchor introduces the GFRP Tie Rod, a high-strength, non-corrosive alternative to steel for formwork, reducing costs and improving durability in global infrastructure projects.

A report on how SupAnchor's innovative self drilling anchor bolt system addresses complex soil challenges, enhancing stability in tunneling and slope stabilization projects across Europe.