In a recent high-profile infrastructure initiative across the Alpine regions of Europe, engineers encountered formidable geotechnical challenges, including unstable rock formations, high groundwater levels, and steep slopes. SupAnchor's self drilling anchor system was strategically deployed to ensure foundational integrity and slope stabilization, playing a critical role in the project's success. This industry news report delves into the technical applications, industry relevance, and brand value of SupAnchor's solutions, tailored for European and American readers seeking insights into modern geotechnical engineering.

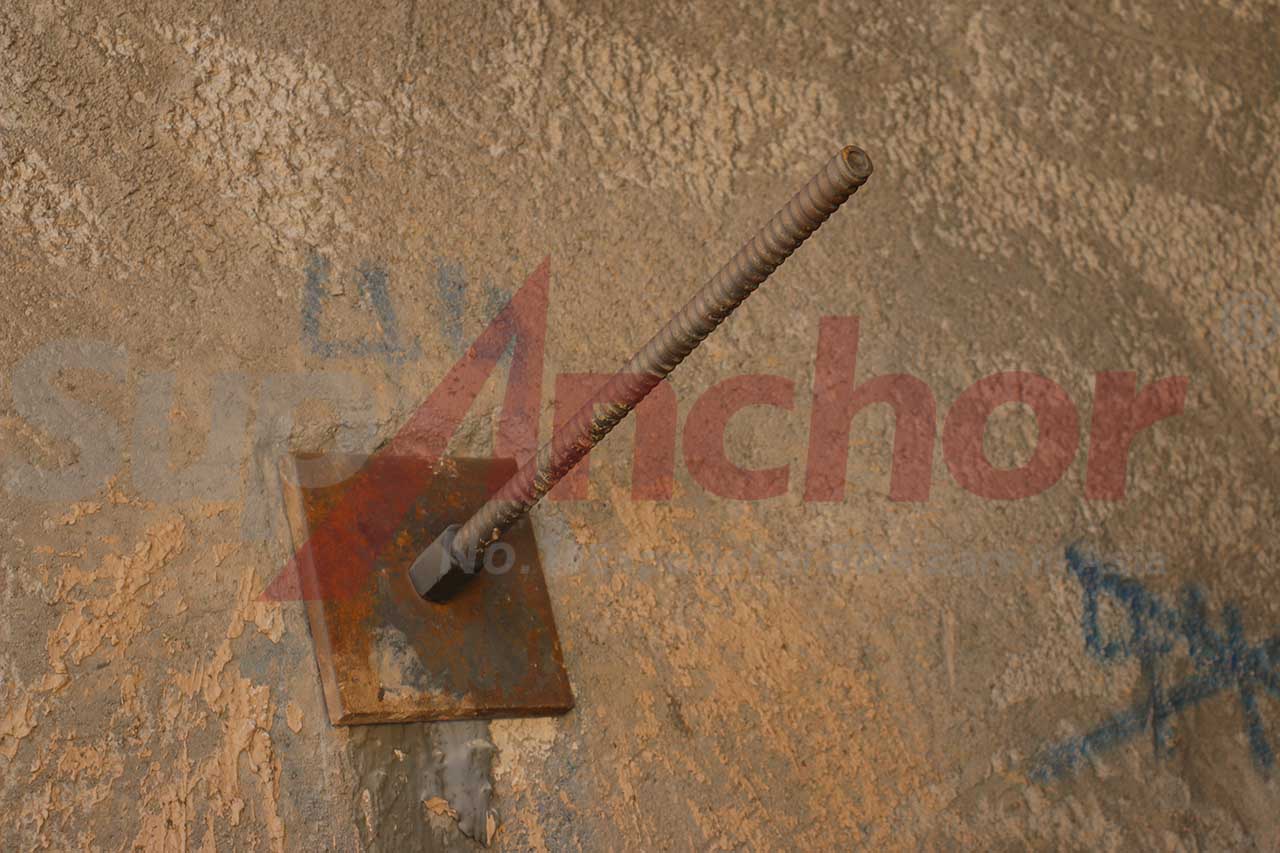

The construction site image illustrates the efficient installation of SupAnchor's hollow bar anchors in a slope stabilization effort. The self drilling anchor bolt system enables simultaneous drilling and grouting, significantly reducing installation time while enhancing bond strength in difficult terrains. This approach not only mitigates risks associated with ground movement but also optimizes resource allocation, making it a preferred choice for tunneling and foundation support projects worldwide.

SupAnchor's geotechnical reinforcement system is engineered to address specific site challenges with precision. Key product parameters, derived from the company's extensive portfolio, include tensile strength, diameter, length, and corrosion protection, all designed to solve real-world issues. Below is a detailed table outlining these specifications:

| Parameter | Value | Application Benefit |

|---|---|---|

| Tensile Strength | Up to 600 kN | Provides high load-bearing capacity for critical supports in retaining walls and tunneling. |

| Diameter | 25 mm to 51 mm | Offers versatility for various project scales, from micropile hollow bar anchors to larger ground anchor bolts. |

| Length | Up to 15 m | Enables deep anchoring in challenging geologies, ideal for rock bolts in underground mining and slope stabilization. |

| Corrosion Protection | Hot-dip Galvanized | Ensures durability in harsh environments, enhancing the longevity of the ground stabilization anchor system. |

These specifications allow the drill-and-grout bolt to effectively combat issues like soil erosion and structural instability. For instance, the high tensile strength supports heavy loads in civil engineering projects, while the corrosion protection extends service life in wet conditions. The self drilling anchor for retaining walls integrates seamlessly with modern construction techniques, reducing labor costs and improving safety on-site.

The deployment of SupAnchor's products aligns with emerging global trends in infrastructure development, where geotechnical safety and efficiency are paramount. As urbanization accelerates and climate change intensifies, there is a growing demand for reliable ground anchor bolt systems in transportation, mining, and public works. This project exemplifies how innovative solutions can address complex challenges, such as:

Moreover, the geotechnical reinforcement system contributes to cost savings by streamlining installation processes, making it a valuable asset for projects ranging from highway expansions to dam reinforcements. As industries worldwide prioritize risk mitigation, SupAnchor's SDA bolt factory direct supply model ensures timely access to quality components, fostering collaboration across engineering teams.

SupAnchor, recognized as a leading soil nail system manufacturer, emphasizes a triad of core values: Professionalism, Innovation, and Collaboration. With ISO 9001 certification and a global project portfolio spanning Europe, North America, and Asia, the company leverages cutting-edge research to develop customized solutions. Their anchor bolt system for geotechnical engineering is designed not only for performance but also for ease of integration with existing methodologies.

The product image showcases the precision engineering of SupAnchor's self drilling anchor bolt, highlighting features like the hollow bar design that facilitates efficient grouting and load distribution. By maintaining a focus on R&D and customer-centric approaches, SupAnchor drives advancements in ground stabilization anchor systems, ensuring that projects meet stringent regulatory standards while achieving operational excellence.

In summary, this case study underscores the pivotal role of SupAnchor's self drilling anchor system in modern infrastructure. As geotechnical challenges evolve, such innovations will continue to shape the industry, promoting safer and more efficient construction practices globally. For more insights into geotechnical solutions, visit SupAnchor's official website.

SupAnchor's self drilling anchor bolt system provides robust foundation support in complex geotechnical conditions, highlighting innovation in ground stabilization for global infrastructure.

SupAnchor unveils the SupPump SDA Grout Pump models Sup2000 and Sup5000, enhancing productivity in tunneling, mining, and civil engineering with advanced technical features.

How SupAnchor's self drilling anchor bolts are solving complex geotechnical challenges in a Swiss tunneling project, highlighting innovation and industry trends.

SupAnchor launches the SupFRP® GFRP Hollow Injection Bolt, offering high tensile strength and pressure resistance for enhanced safety in slope stabilization, tunneling, and mining projects globally.

SupAnchor's innovative self drilling anchor system addresses complex geotechnical challenges in a recent construction project, highlighting its role in foundation support and industry safety trends.