In today's rapidly evolving construction landscape, the demand for durable and resilient materials is paramount, especially in challenging environments such as coastal regions, industrial zones, and infrastructure hubs. SupAnchor®, a leader in geotechnical and reinforcement solutions, has launched its SupFRP® GFRP Reinforcement Rebar, a high-performance alternative designed to address these pressing needs. This product emerges as a response to increasing concerns over corrosion and structural integrity in long-term projects, offering a innovative approach to concrete internal reinforcement.

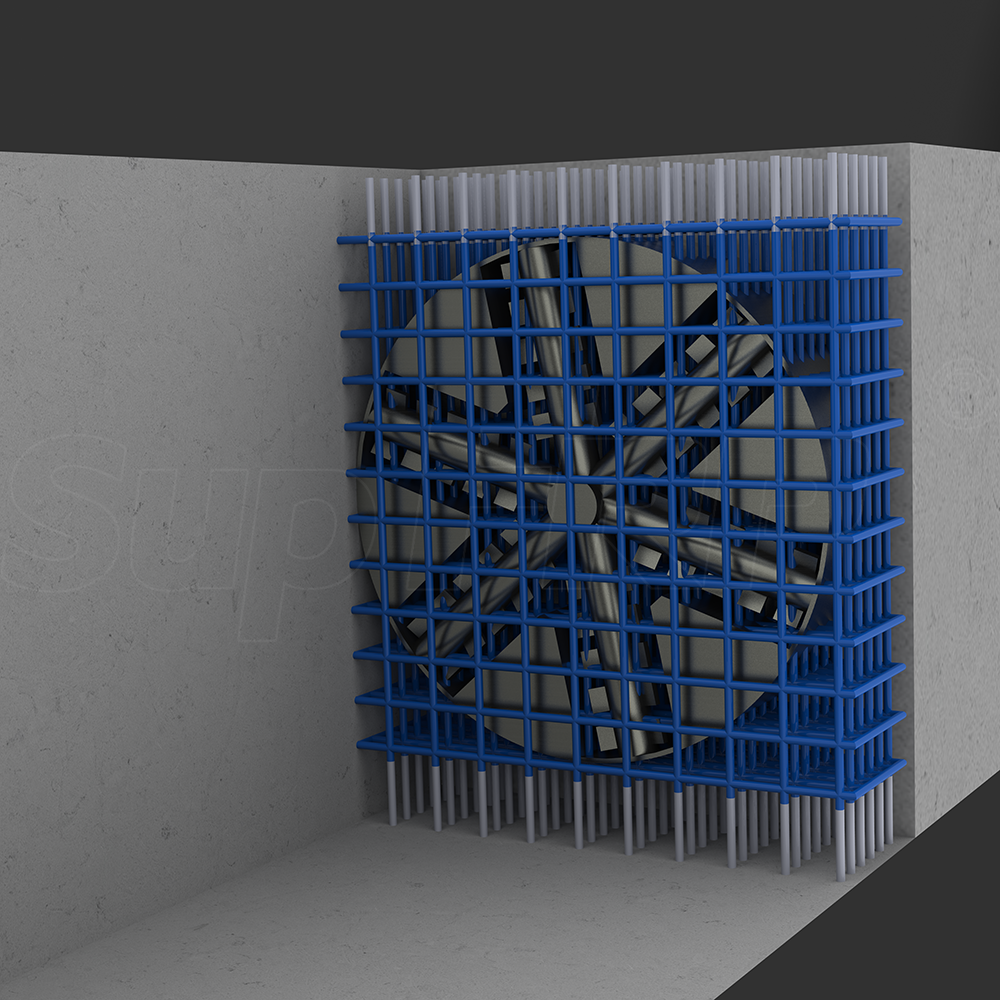

The SupAnchor® GFRP Reinforcement Rebar is meticulously crafted using high-quality corrosion-resistant resin and fiberglass materials, ensuring permanent application in aggressive conditions. Developed through extensive research and development, this product can be factory-produced into various shapes to meet specific construction requirements, from soft-eye excavations to sea walls. As global infrastructure projects expand, SupAnchor's role in enhancing engineering adaptability and safety becomes increasingly vital.

To understand the value of the SupAnchor® GFRP Reinforcement Rebar, it's essential to delve into its technical data. The product boasts a range of sizes, each with optimized parameters for different load-bearing scenarios. Key features include high tensile strength, excellent bonding with concrete, and non-conductive properties, making it ideal for applications where electromagnetic interference is a concern.

From the provided technical data, several critical parameters stand out:

To illustrate this, here is a table summarizing selected sizes:

| Model | Outside Diameter (mm) | Guaranteed Tensile Load (kN) | Tensile Strength (MPa) | Weight (kg/m) |

|---|---|---|---|---|

| ReB-8 | 9 | 50.3 | 1000 | 0.125 |

| ReB-16 | 18 | 201 | 1000 | 0.50 |

| ReB-32 | 36 | 720 | 900 | 2.00 |

This data highlights how the SupAnchor® GFRP rebar addresses engineering challenges such as load distribution and environmental durability. For instance, in bridge deck construction, the high tensile strength and corrosion resistance prevent premature failure, reducing maintenance costs and enhancing safety. The waved thread structure ensures excellent bonding with concrete, facilitating easy installation and long-term stability.

The versatility of the SupAnchor® GFRP Reinforcement Rebar is evident in its wide range of applications. Key scenarios include:

These applications underscore the product's engineering adaptability, allowing for cost-effective solutions across various construction phases. The ease of cutting and handling further enhances on-site efficiency, making it a practical choice for modern projects.

The introduction of the SupAnchor® GFRP Reinforcement Rebar aligns with global trends towards sustainable and resilient infrastructure. As cities expand and climate challenges intensify, materials that offer longevity and reduced environmental impact are crucial. SupAnchor's commitment to innovation is reflected in its ISO-certified manufacturing processes and ongoing R&D efforts, which have led to breakthroughs in geotechnical reinforcement systems.

SupAnchor's influence extends beyond product development to collaborative projects worldwide. From tunneling in Europe to mining operations in the Americas, the brand's solutions have been integral to geotechnical safety and efficiency. This reinforces the core message of being professional, innovative, and collaborative—values that resonate with engineers and stakeholders seeking reliable partners.

In conclusion, the SupAnchor® GFRP Reinforcement Rebar represents a significant advancement in concrete reinforcement technology. By combining high performance with practical benefits, it sets a new standard for durability and adaptability in construction. As the industry evolves, SupAnchor continues to lead with solutions that address real-world challenges, from self drilling anchor systems to advanced rebar products.

Industry news on SupAnchor's self drilling anchor bolt application in a complex geology tunnel project, featuring technical parameters and global relevance.

SupAnchor introduces high-performance GFRP reinforcement rebar, offering superior corrosion resistance and tensile strength for diverse construction needs in harsh environments.

SupAnchor's self drilling anchor systems provide critical ground stabilization in a challenging hydropower project, highlighting innovation in geotechnical engineering for infrastructure development.

SupAnchor launches the SupCT Bolt System, a self drilling anchor bolt with high ductility and corrosion resistance, ideal for tunneling and mining projects worldwide.

Report on SupAnchor's application of self drilling anchor bolts for slope stabilization in a major infrastructure project, highlighting technical parameters and industry relevance.