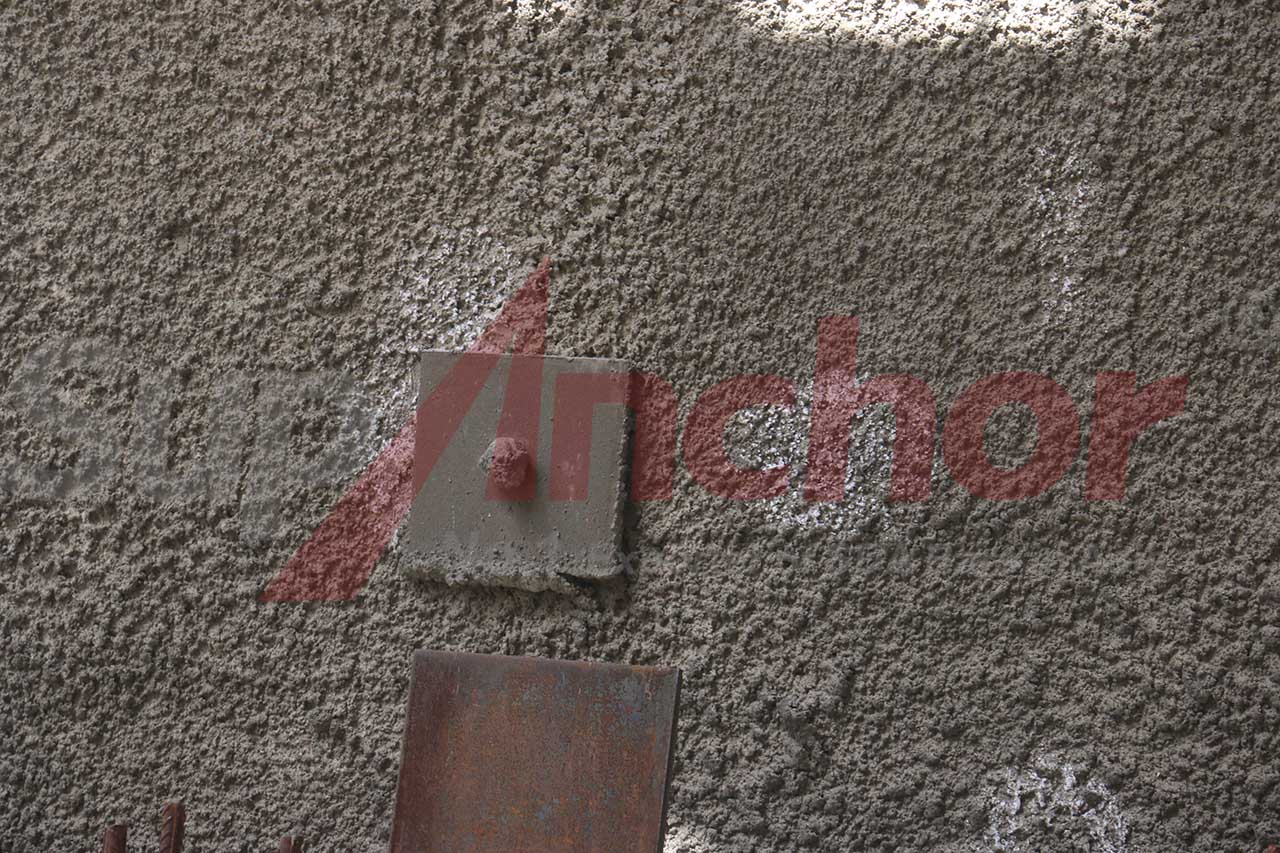

In an era where geotechnical engineering faces escalating demands from complex ground conditions, SupAnchor, Asia's leading manufacturer of self-drilling anchors, has launched the SupUTS self-drilling hollow anchor. This innovation addresses critical challenges in deep foundations, tunnel support, and slope stabilization, where traditional methods often fall short due to inefficiencies and inadequate strength. The SupUTS series is engineered to deliver superior performance in unconsolidated soils and harsh environments, reinforcing SupAnchor's commitment to advancing geotechnical reinforcement systems worldwide.

The SupUTS series leverages a 3-in-1 integration principle, where a ribbed hollow steel bar serves as a drilling rod, injection tube, and reinforcing bar simultaneously. This design streamlines construction processes, reducing labor and time in challenging scenarios like soft soil or deep excavations. With the "UTS" designation indicating a focus on ultimate tensile strength, these anchors offer enhanced mechanical properties, making them ideal for high-load applications such as bridge foundations or industrial structures.

Key parameters from the product introduction highlight its robust performance. For instance, the SupUTS models provide significant load capacities, ensuring reliability in demanding projects. Below is a table summarizing technical data for core models, illustrating how specifications address engineering needs:

| Model | Outside Diameter (mm) | Ultimate Load (kN) | Yield Load (kN) | Weight (kg/m) |

|---|---|---|---|---|

| SSTR32/360 | 32 | ≥360 | ≥280 | 3.5-4.0 |

| SSTR38/660 | 38 | ≥660 | ≥520 | 6.3-6.8 |

| SSTR51/930 | 51 | ≥930 | ≥730 | 9.0-9.5 |

These self-drilling anchor bolts are designed to meet high tensile demands, with standardized threads ensuring compatibility and rapid installation. The rib structure maximizes bond with grouting materials, reducing soil damage and maintaining structural stability. In applications like tunnel reinforcement or deep slope stabilization, this geotechnical reinforcement system mitigates risks associated with conventional methods, offering a drill-and-grout bolt solution that enhances safety and efficiency.

To adapt to diverse environmental conditions, the SupUTS series offers three anti-corrosion treatments: hot-dip galvanizing for general use, SupCoating (a dual-layer of HDG and epoxy) for moderate corrosion resistance, and stainless steel for highly corrosive settings like coastal projects. This flexibility extends service life, making the hollow bar anchor suitable for long-term applications in water conservancy or industrial zones, where durability against harsh media is critical.

The SupUTS self-drilling anchor system is well-suited for heavy-duty geotechnical projects, including deep foundation reinforcement for skyscrapers, support for large-span bridges, and stabilization in soft soil environments. Its high-strength performance addresses global infrastructure needs, particularly in mining, tunneling, and transportation sectors where ground anchor bolt reliability is paramount. By reducing construction delays and enhancing load-bearing capacity, this product contributes to geotechnical safety and sustainable development, aligning with industry trends towards more resilient engineering solutions.

SupAnchor's development of the SupUTS series underscores its role as a professional and innovative leader in the self-drilling anchor market. With ISO certifications and a history of successful global projects, the brand emphasizes collaborative R&D to meet evolving engineering challenges. As a top soil nail system manufacturer and ground anchor bolt factory, SupAnchor continues to drive advancements in geotechnical technology, reinforcing its message of delivering reliable, high-performance products for complex applications.

In conclusion, the SupUTS self-drilling hollow anchor represents a significant step forward in geotechnical engineering, offering enhanced strength, versatility, and durability. It exemplifies SupAnchor's commitment to innovation and collaboration, setting new benchmarks for the industry while supporting critical infrastructure projects worldwide.

SupAnchor's self drilling anchor bolt system enhances safety in London's metro expansion, addressing soft soil and high groundwater with advanced geotechnical reinforcement.

SupAnchor introduces the SupUTS self-drilling anchor system, offering enhanced load capacity and anti-corrosion options for challenging ground conditions, supporting global infrastructure development.

SupAnchor's innovative self drilling anchor system addresses complex geological challenges in infrastructure projects, ensuring stability and reducing construction risks with advanced geotechnical reinforcement.

SupAnchor's new GFRP tie rod offers a permanent, corrosion-resistant alternative to steel, enhancing safety and reducing costs in global construction projects.

An in-depth look at how SupAnchor's self-drilling anchor bolts provided critical ground stabilization in a challenging geotechnical project, showcasing technical innovation and industry-wide implications for safety and efficiency.