In the challenging landscapes of European and American infrastructure projects, from rugged mountain slopes to deep urban tunnels, engineers face persistent issues with unstable ground conditions and corrosion-prone materials. SupAnchor, a leader in geotechnical reinforcement systems, addresses these challenges with its SupFRP® GFRP Hollow Injection Bolt, a core product designed to integrate drilling and grouting for superior performance. This innovative self drilling anchor bolt is transforming how professionals approach slope stabilization, TBM face support, and other critical applications, ensuring durability and safety in complex geological environments.

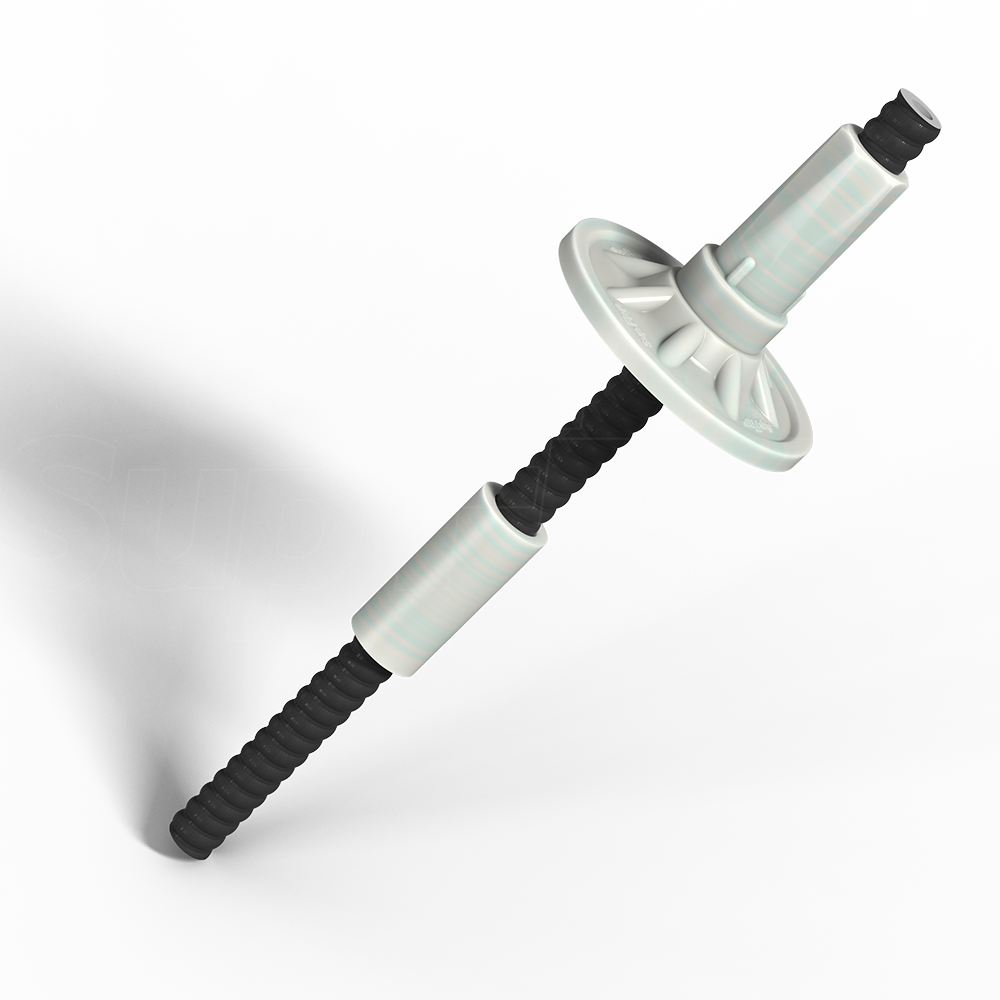

The SupAnchor hollow injection bolt combines the functions of a rock bolt and injection system, allowing it to remain in place post-grouting to bear loads alongside plates and nuts. Its key advantages include high pressure resistance, low weight for easy handling, and excellent bond force with grouting materials, which enables full grouting under high pressure to improve project outcomes. For instance, in confined ground conditions or soft rock stabilization, the bolt's high tensile load and cuttability ensure adaptability to varying site requirements.

To illustrate the technical prowess, here are key parameters from the product lineup, highlighting how these specs address common engineering hurdles such as load-bearing capacity and corrosion mitigation in harsh environments.

| Model | Outside Diameter (mm) | Guaranteed Tensile Load (kN) | Pressure Resistance (MPa) | Weight (kg/m) | Length Options (m) |

|---|---|---|---|---|---|

| H25/220 | 25 | 220 | 5 | 0.64 | 2-11 |

| H28/320 | 28 | 320 | 5 | 0.88 | 2-11 |

| H32/360 | 32 | 360 | 5 | 1.20 | 2-11 |

| H38/490 | 38 | 490 | 5 | 1.5 | 2-11 |

| H22/230 | 22 | 230 | 18 | 0.58 | 2-11 |

| H25/300 | 25 | 300 | 30 | 0.79 | 2-11 |

This geotechnical reinforcement system leverages a tensile E-modulus of 45 GPa and ultimate strain of 2.0% across models, providing reliable performance under stress. The hollow bar anchor design facilitates efficient grout flow, enhancing bond strength and reducing installation time, which is critical in projects like forepoling or permanent applications where speed and durability are paramount.

The versatility of the SupAnchor self drilling anchor system extends to numerous high-stakes environments. In slope stabilization efforts across mountainous regions, the bolt's high corrosion resistance ensures long-term integrity against weather elements. For tunneling and mining operations, such as TBM face support, the product's ability to handle high pressures and loads improves safety and reduces downtime. These applications align with growing global demands for sustainable infrastructure, where drill-and-grout bolts contribute to safer urban development and resource extraction.

By addressing these needs, SupAnchor supports advancements in geotechnical engineering, reducing risks and costs associated with ground failures. The self drilling anchor bolt technology is particularly valuable in regions with soft rock or variable soil conditions, offering a reliable solution for engineers seeking to optimize project outcomes.

As a professional leader in the field, SupAnchor emphasizes R&D and innovation, holding ISO certifications that validate its quality standards. The company's global projects, from European railways to American mining sites, demonstrate a collaborative approach with clients to tailor solutions for specific challenges. This brand message of being professional, innovative, and collaborative is embedded in every product, ensuring that the hollow injection bolt not only meets technical specs but also fosters trust in long-term partnerships.

The integration of this geotechnical reinforcement system into diverse projects underscores SupAnchor's role in enhancing safety and efficiency worldwide. By continuously improving materials and designs, the company sets a benchmark for the industry, inspiring confidence among stakeholders in infrastructure development.

In conclusion, SupAnchor's GFRP Hollow Injection Bolt represents a significant leap forward in geotechnical reinforcement, blending advanced engineering with practical adaptability. As demands for robust infrastructure grow, this product stands ready to support a safer, more resilient built environment, driven by SupAnchor's unwavering commitment to excellence.

SupAnchor's geotechnical reinforcement system, featuring self drilling anchor bolts, ensures slope stability in a high-risk Alpine construction site, highlighting innovation in civil engineering.

SupAnchor introduces advanced hollow injection bolts for slope stabilization and tunneling, offering high tensile load, corrosion resistance, and easy installation to enhance project quality and safety globally.

SupAnchor's self-drilling anchor bolts deliver critical ground stabilization in complex geology, advancing infrastructure safety and geotechnical innovation worldwide.

SupAnchor introduces the SupShell Expansion Rock Bolt System, providing immediate anchorage and superior grip for strata control in tunneling, mining, and geotechnical applications.

SupAnchor's self drilling anchor system addresses complex geology in a large-scale project, highlighting innovation in geotechnical engineering for global infrastructure trends.