In a major infrastructure project across challenging European terrains, engineers grappled with corrosion issues in traditional steel formwork systems, leading to increased maintenance and replacement costs. SupAnchor®, a leader in geotechnical reinforcement systems, has stepped in with its innovative SupFRP® GFRP Tie Rod, designed to provide a durable, permanent solution for formwork applications. This product eliminates the need for removal upon project completion, significantly cutting transportation and storage expenses while enhancing structural integrity.

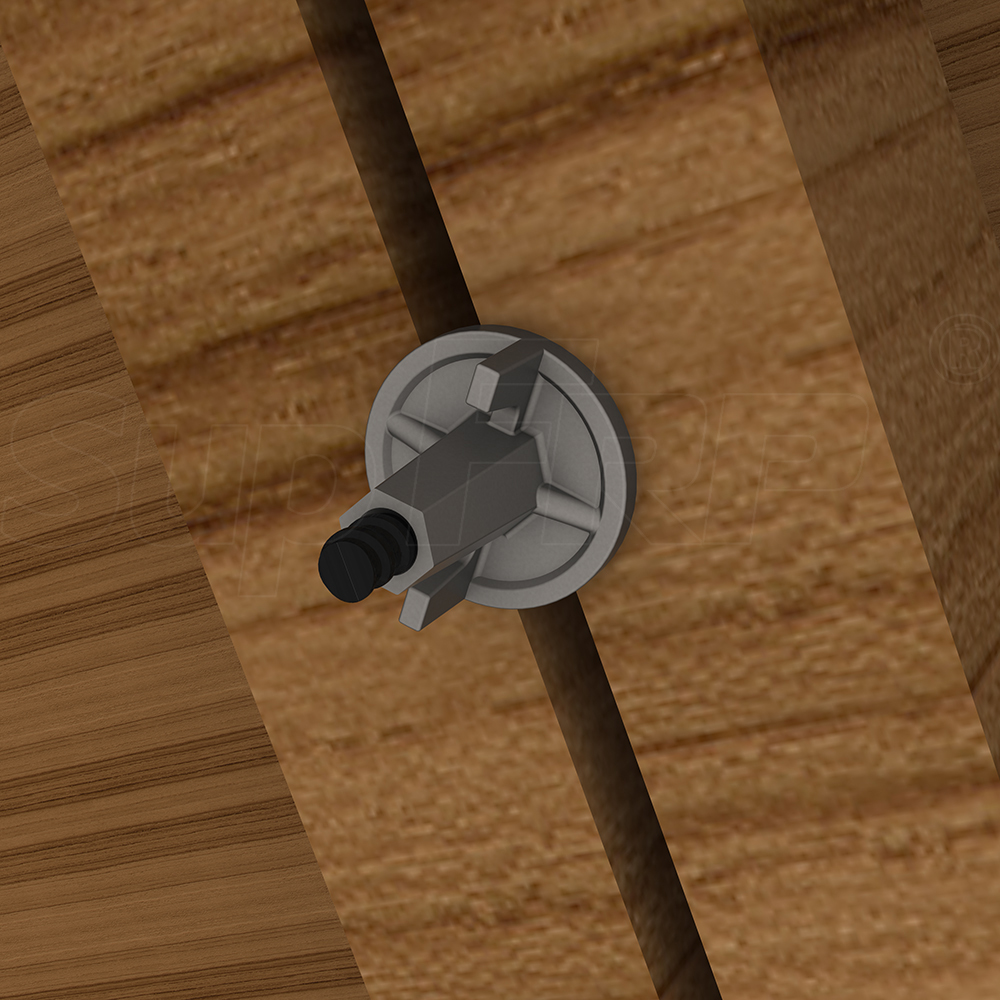

The SupFRP® GFRP Tie Rod is engineered to meet the rigorous demands of modern construction, with key specifications that address common formwork challenges such as corrosion, weight, and adaptability. Unlike steel rods, it boasts high corrosion resistance, non-conductive properties, and compatibility with standard accessories, making it ideal for diverse site conditions. For instance, in a tunneling project with high moisture levels, this self drilling anchor bolt alternative ensures longevity without compromising safety.

The following table highlights critical technical data from the product introduction, demonstrating how these parameters solve engineering problems:

| Parameter | T15/130 | T20/250 |

|---|---|---|

| Outside Diameter (mm) | 17 | 22 |

| Guaranteed Tensile Load (kN) | 130 | 250 |

| Weight (kg/m) | 0.37 | 0.71 |

| Tensile E-Modulus (GPa) | 45 | 45 |

| Ultimate Strain | 2.0% | 2.0% |

With a guaranteed tensile load of up to 250 kN and high end loading capabilities, this hollow bar anchor equivalent ensures stability in large-scale projects, such as mining operations or bridge constructions. The easy handling and cuttability features allow for quick adjustments on-site, reducing labor time and improving efficiency. SupAnchor's focus on innovation is evident in how this product integrates seamlessly into existing drill-and-grout bolt systems, offering a versatile upgrade for geotechnical reinforcement.

The SupFRP® GFRP Tie Rod is primarily applied in formwork, but its benefits extend to various sectors, including tunneling, mining, and geotechnical safety. In European projects, where environmental regulations demand sustainable solutions, this product's non-magnetic and non-conductive properties make it suitable for sensitive areas like underground railways or coastal defenses. For example, in a recent urban development in Germany, engineers used this tie rod to reinforce formwork for a high-rise building, citing reduced long-term costs and enhanced durability against harsh weather.

This aligns with global trends in infrastructure development, where safety and cost-efficiency are paramount. By providing a reliable alternative to steel, SupAnchor contributes to safer construction practices and reduced environmental impact, positioning itself as a key player in the geotechnical reinforcement system market.

SupAnchor's development of the GFRP Tie Rod underscores its dedication to research and development, backed by ISO certifications and a portfolio of successful global projects. The company's collaborative approach with engineers and contractors has led to tailored solutions for complex challenges, such as those in seismic zones or deep excavation sites. As a soil nail system manufacturer and ground anchor bolt factory, SupAnchor leverages its expertise to ensure that products like this tie rod meet international standards for quality and performance.

Brand messages of professionalism, innovation, and collaboration are woven into every aspect of this launch. By focusing on user needs, such as the availability of a demonstration video for application guidance, SupAnchor fosters trust and adoption in the industry. This product not only enhances the company's reputation but also drives forward the adoption of advanced self drilling anchor systems worldwide.

In summary, the SupFRP® GFRP Tie Rod represents a significant advancement in formwork technology, offering practical benefits that resonate with European and American construction sectors. With its robust technical specs and alignment with industry demands, SupAnchor continues to lead in providing innovative geotechnical reinforcement solutions that prioritize safety, efficiency, and sustainability.

SupAnchor's innovative self drilling anchor bolts provide robust geotechnical reinforcement in a European tunneling project, addressing complex soil and rock conditions for enhanced infrastructure safety.

SupAnchor introduces a GFRP tie rod for formwork, offering high corrosion resistance and permanent installation to reduce costs and improve safety in construction projects.

SupAnchor's self drilling anchor system provides critical support in challenging geotechnical projects, highlighting trends in global infrastructure safety and innovation.

SupAnchor's SupUTS self-drilling hollow anchor offers superior tensile capacity and integrated design, streamlining construction in challenging ground conditions for global infrastructure.

SupAnchor's geotechnical reinforcement system, featuring self drilling anchor bolts, ensures slope stability in a high-risk Alpine construction site, highlighting innovation in civil engineering.