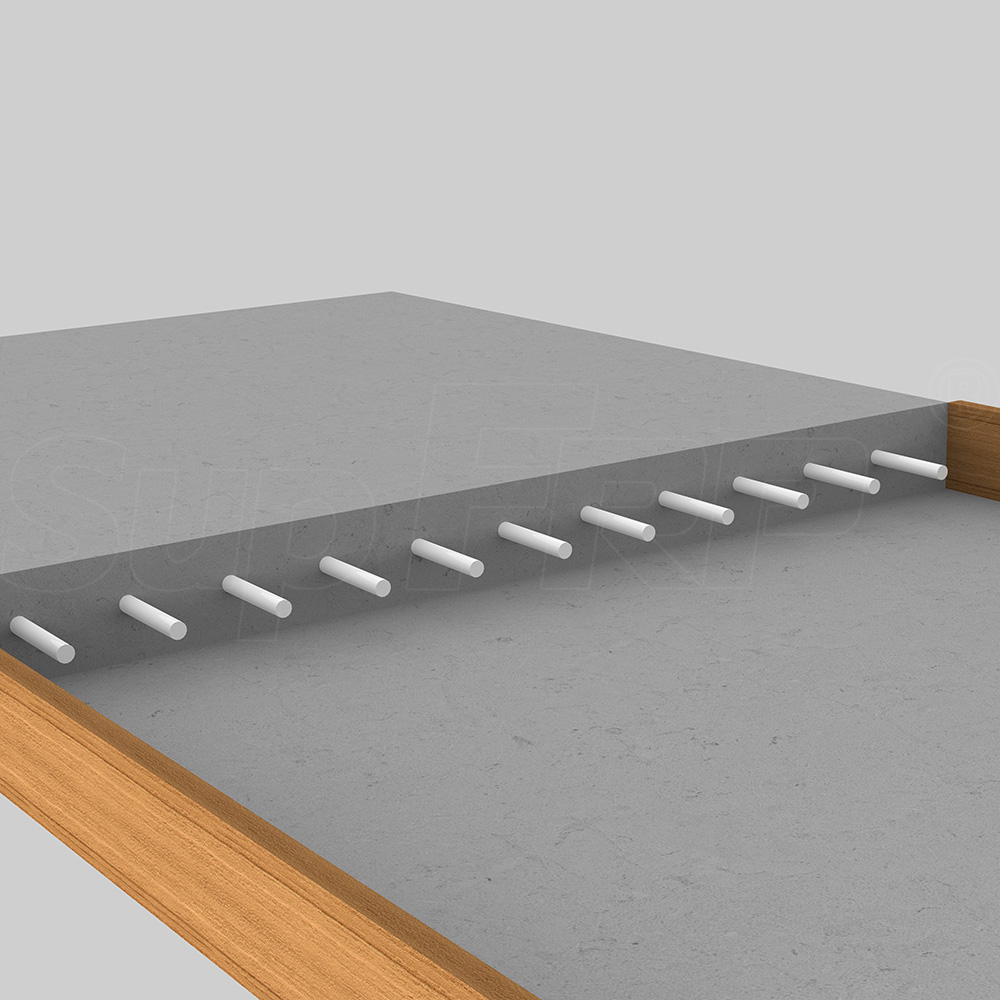

In the face of increasing demands for durable and efficient infrastructure, SupAnchor, a prominent manufacturer in the geotechnical reinforcement industry, has launched the SupFRP® GFRP Dowel Bar. This product is designed to address critical challenges in construction joints, such as thermal expansion and corrosion, which are common in concrete slabs across Europe and America. With applications ranging from urban pavements to environmentally sensitive sites, this innovation highlights SupAnchor's commitment to advancing construction technology through professional and innovative solutions.

The GFRP Dowel Bar is manufactured from premium raw materials and offers customization to meet specific project requirements. It functions as a load transfer device, providing a mechanical link between adjacent concrete slabs while allowing for horizontal movements to accommodate thermal fluctuations. This ensures structural stability and prevents cracking, even under extreme temperature variations. Key advantages include a service life exceeding 100 years, no-rust properties, high strength, superior load transfer efficiency, non-conductive characteristics, and non-magnetic features, making it ideal for a variety of engineering scenarios.

To support engineers in selecting the appropriate model, SupAnchor provides detailed technical data for various sizes. The product's compatibility with other geotechnical reinforcement systems, such as self drilling anchor systems and drill-and-grout bolts, enhances its adaptability in complex projects. For instance, in jointed rigid pavement, the dowel bar's ability to handle transverse shear loads ensures long-term durability, while its non-interfering properties make it suitable for work areas with electromagnetic sensitivities, such as near medical facilities or communication hubs.

Below is a summary of the technical specifications for the GFRP Dowel Bar models:

| Model | Outside Diameter (mm) | Transverse Shear Load (kN) | Nominal Cross Sectional Area (sq. m) | Coefficient of Thermal Expansion (x10-6/℃) | Weight (kg/m) |

|---|---|---|---|---|---|

| DB16 | 16 | 35 | 200 | 9-11 | 0.43 |

| DB20 | 20 | 55 | 310 | 9-11 | 0.67 |

| DB25 | 25 | 85 | 490 | 9-11 | 1.05 |

| DB32 | 32 | 130 | 800 | 9-11 | 1.71 |

| DB38 | 38 | 180 | 1130 | 9-11 | 2.41 |

| DB45 | 45 | 255 | 1590 | 9-11 | 3.37 |

These parameters allow for precise engineering decisions, ensuring that the dowel bar meets load requirements and environmental conditions, thereby solving common challenges like corrosion and thermal stress in infrastructure projects.

The versatility of the GFRP Dowel Bar extends to numerous applications, including jointed rigid pavement, construction joints, embankments, and mechanically stabilized earth (MSE) walls. In pavements, it enhances durability by reducing maintenance needs and extending lifespan. For environments with electromagnetic sensitivities, such as airports or research facilities, its non-conductive and non-magnetic properties eliminate risks of interference, aligning with strict safety standards in Europe and America.

Moreover, the product integrates well with SupAnchor's broader portfolio, including soil nail systems and hollow bar anchors, which are essential for geotechnical reinforcement. This adaptability makes it a valuable component in tunneling, mining, and urban development projects, where reliable load transfer is critical for safety and efficiency. By offering customization options, SupAnchor ensures that the dowel bar can be tailored to specific site conditions, further demonstrating its engineering adaptability and market value.

SupAnchor's GFRP Dowel Bar contributes significantly to global infrastructure by addressing key issues such as longevity and corrosion resistance. With a 100+ year service life, it reduces lifecycle costs and promotes sustainability in projects like highways, bridges, and industrial facilities. The company's focus on innovation is supported by ISO certifications and a track record of successful implementations worldwide, including collaborations on major tunneling and mining ventures.

The product's role in enhancing geotechnical safety is particularly notable, as it provides reliable support in challenging conditions, such as in embankments or areas prone to seismic activity. By incorporating advanced technologies like self drilling anchor bolts and drill-and-grout systems, SupAnchor reinforces its position as a leader in the ground anchor bolt manufacturing sector. This not only boosts brand influence but also fosters a collaborative approach with engineers and contractors to achieve optimal project outcomes.

SupAnchor has established itself as a trusted name in the geotechnical reinforcement industry, driven by continuous research and development. The introduction of the GFRP Dowel Bar underscores the company's commitment to professionalism, innovation, and collaboration. With a global presence and a focus on customer-centric solutions, SupAnchor is poised to shape the future of construction technology, particularly in regions with stringent environmental and safety regulations.

As infrastructure demands grow, products like the GFRP Dowel Bar will play a pivotal role in ensuring resilient and efficient structures. SupAnchor's ongoing investments in R&D and quality assurance promise further advancements, solidifying its reputation for delivering cutting-edge products that meet the evolving needs of the construction sector.

SupAnchor's innovative self drilling anchor bolt system provides robust geotechnical reinforcement, addressing complex geological challenges in modern infrastructure projects across Europe and America.

SupAnchor introduces its GFRP Dowel Bar, offering superior load transfer, corrosion resistance, and a 100+ year service life for pavements and sensitive environments.

A European infrastructure project overcomes soil instability with SupAnchor's self drilling anchor system, highlighting innovation in geotechnical reinforcement for tunneling and slope stabilization.

SupAnchor introduces a GFRP tie rod for formwork, featuring high corrosion resistance, permanent installation, and cost savings, supporting sustainable construction practices in global infrastructure.

A major infrastructure project in Europe leverages SupAnchor's self drilling anchor bolts for slope stabilization and foundation support in complex geological conditions.